Operating Instructions

19

• For profile tubes:

For some drive adapters, tolerances of the channel widths in different roller tubes

can be balanced by turning the drive adapter in a different channel slot. These chan-

nel slots come in different sizes and make it an exact fit possible when the drive is

installed.

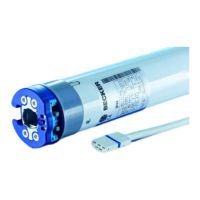

• For round tubes:

Release the tube from the motor died in advance, so that the cam of the ring can

also be inserted into the tube. The cam of the ring must not engage with the tube.

For rings without pulling cams, the roller tube must be connected to the ring by a

4.8 x 10 mm sheet-metal screw.

4. Assemble the tubular drive with the relevant ring (A) and drive adapter (B). Insert the

tubular drive with the pre-assembled ring and drive adapter into the tube as shown.

Ensure that the ring and drive adapter are correctly positioned in the tube. (Fig. 7)

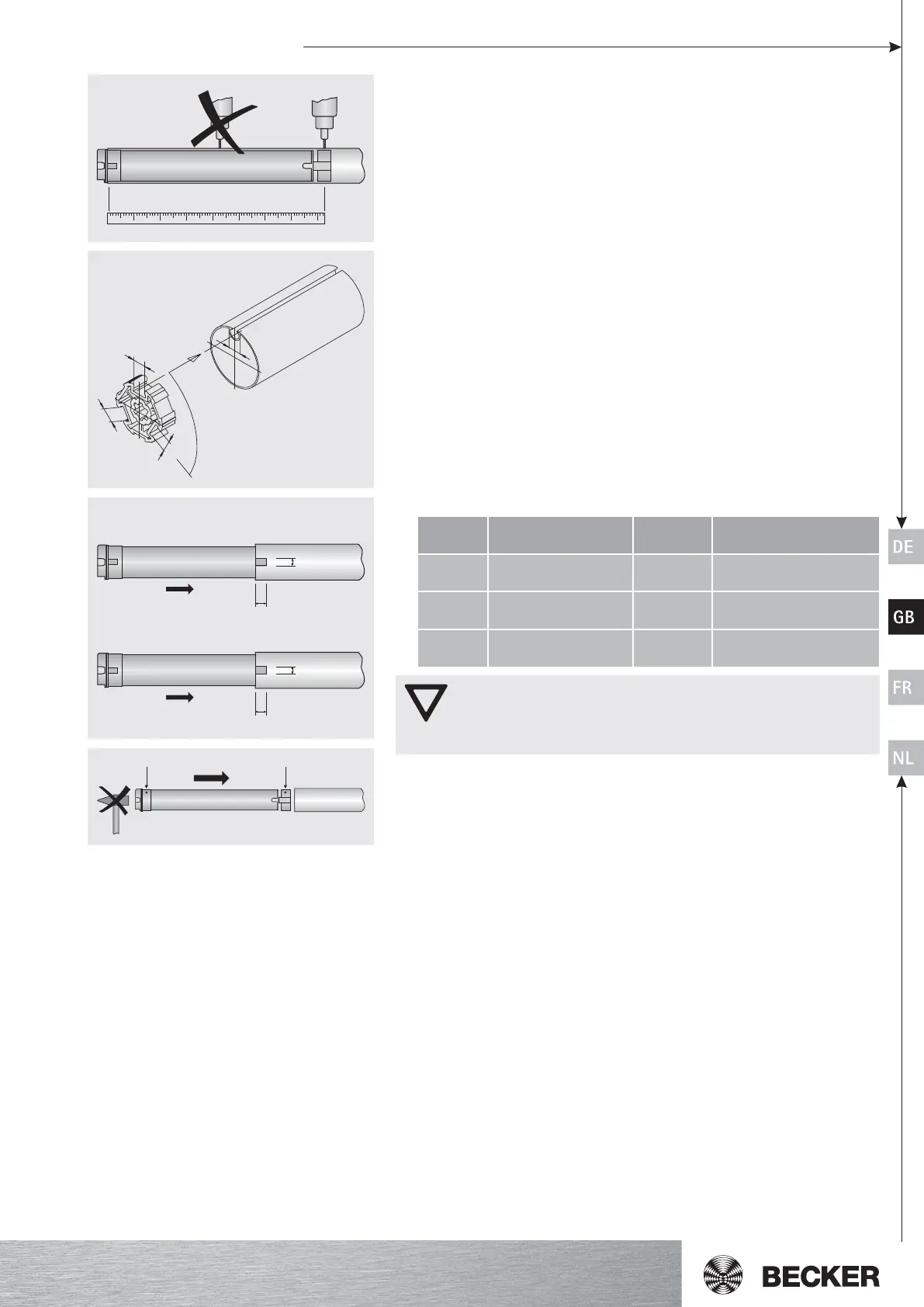

The drive adapter of the tubular drive is connected to the roller tube as follows:

Attention

When drilling into the roller tube, never drill near the tubular drive!

The tubular drive must not be hit into the tube or dropped into the

roller tube!

Becker also recommends that the counter bearing be joined to the roller tube.

5. Hang the tube in the bracket and secure the motorhead piece in the drive bracket.

6. Hang the mounted unit consisting of tube, tubular drive and thrust bracket in the

bracket.

5

4

A

B

C

B

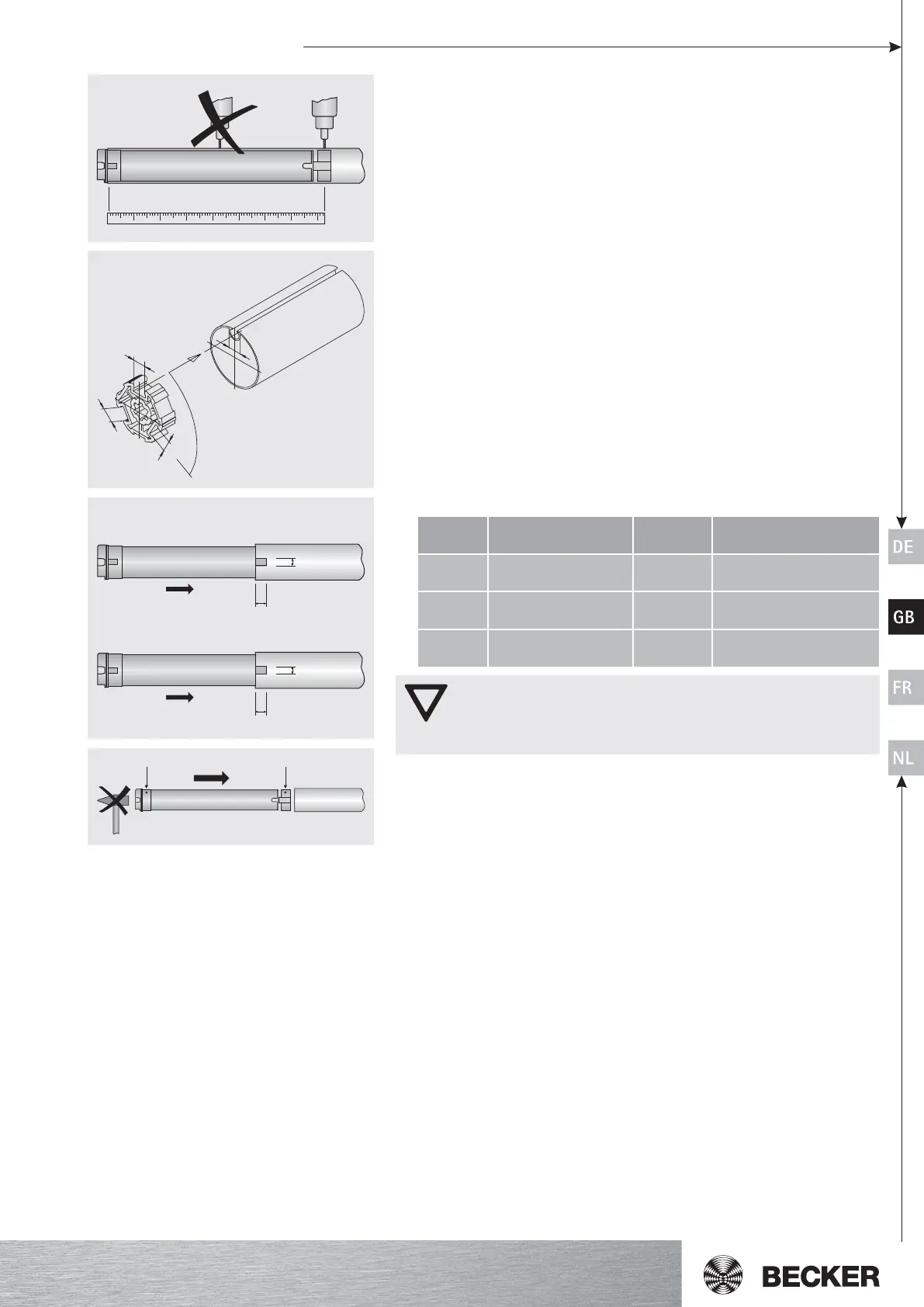

3. Before fitting in the barrel, take the measurement from barrel end to the centre of

the drive adapter and mark on the barrel (Fig. 4).

foeziS

]mm[evird

Ø–sebutrettuhsrelloR

]mm[

.xameuqroT

]mN[

swercsgninetsaF

)x4(srevirdrof

54Ø

rocitsalpmm07-06

retpadaevirdtsaceid

05

latem-teehsdedaeh-talf

2897NID01x3.6TSwercs

85Ø

mm021-36

retpadaevirdtsaceid

021

latem-teehsdedaeh-talf

2897NID01x5.9TSwercs

85Ø

mm331-58

retpadaevirdmuinimula

021

61x8Mswercsdedaeh-talf

1997NID

7

AB

6

7,5mm

11mm

R8/17PS(+) - R50/11PS(+)

8,5mm

18mm

R44/14 - R120/11PS(+) PS(+)

Loading...

Loading...