Do you have a question about the Beckman Coulter IMMAGE 800 and is the answer not in the manual?

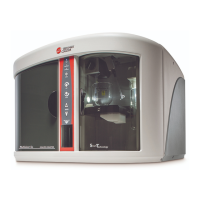

Provides a basic overview of the IMMAGE 800 Immunochemistry System and its intended use.

Explains the scope of the manual and conventions used for guidance.

Covers warranty, service, precautions, hazards, and symbols for safe instrument operation.

Details the physical components of the IMMAGE 800 system.

Describes key instrument parts like the Reagent Compartment and Reaction Module.

Covers specifications and connections for the computer and printer.

Provides an introduction to the graphical user interface (GUI) and basic functions.

Details instrument specifications, power requirements, and environmental conditions.

Explains the scientific principles behind Rate Nephelometry and Rate Turbidimetry.

Describes how light scatter signals are developed and measured during reactions.

Explains the necessity and process of antigen excess (AGXS) testing.

Details calibration curves and system calibration processes.

Provides instructions for the power-on sequence of the IMMAGE 800 system.

Outlines the recommended sequence for powering off the IMMAGE 800 system.

Explains procedures for recovering files and databases after system errors or power outages.

Covers customization of system features for laboratory requirements.

Details how to define, clear, and insert chemistries into the menu.

Explains how to define, edit, and delete chemistry panels.

Covers enabling/disabling symbologies and setting bar code parameters.

Describes how to define, edit, and clear reference intervals and critical ranges.

Covers selecting report formats, defining headers, and disabling automatic printing.

Details available calculations, custom calculations, and enabling/disabling them.

Explains how to select units for reporting and restoring default units.

Covers configuring parameters for laboratory information system (LIS) connection.

Defines default sample types, replicates, and post-run summary time search.

Guides through defining custom reagent chemistry protocols and parameters.

Covers reagent status, loading parameters, and managing buffers/diluents.

Details the process of calibrating the system, including status and history.

Covers essential pre-run checks for sample racks, dilution segments, and reagents.

Guides on entering sample identification, test selection, and options.

Explains how to select predefined panels or individual chemistries for analysis.

Details how to select sample types like Serum, Plasma, or Urine.

Covers the entry of patient information such as name, ID, and age.

Explains how to enable or disable antigen excess testing for individual samples.

Describes how to link samples for special calculations.

Covers defining and programming control samples for quality assurance.

Details how to program samples for priority STAT analysis.

Provides steps for loading samples and initiating a run.

Explains how to pause the system for sample loading or other operations.

Covers options for rerunning samples, including editing programs.

Describes how to request lists of samples or summaries of pending/incomplete tests.

Details procedures for clearing samples by ID or rack/position.

Summarizes routine procedures for bar code and host computer capabilities.

Discusses how to recall and print patient and control results.

Provides steps to recall results using Sample ID.

Details how to recall results based on rack and position.

Explains how to recall results using Patient ID or Control ID.

Describes how to recall results using the Patient Name.

Covers recalling results based on specific date and time ranges.

Provides instructions for printing recalled results in various formats.

Summarizes the QC program, Westgard Rules, and available features.

Explains QC rules like Z-score, 1-2S, 1-3S, and accuracy/precision flags.

Details the minimum information required to save a control definition.

Covers editing control information such as mean, SD, and Control ID.

Allows the operator to review, delete, or print control definitions.

Provides steps to delete control definitions from various screens.

Explains how to display and print QC files by control name or file number.

Displays results with interpretations and allows data point deletion.

Details how to access and print cumulative QC data.

Shows QC results graphically relative to assigned mean and standard deviation.

Explains how to save control information and QC View data to a floppy diskette.

Covers reviewing archived QC data from a floppy diskette.

Divides utilities into Maintenance, Troubleshooting, and Replacing Parts sections.

Covers daily, monthly, and as-indicated maintenance procedures.

Lists tools and supplies needed for maintenance procedures.

Provides essential safety precautions for performing maintenance.

Details the scheduled daily checks and cleaning tasks.

Covers maintenance tasks performed as needed, such as replacing cuvettes.

Guides on diagnosing instrument problems and using error messages.

Explains how to access, display, copy, clear, and print the system event log.

Provides procedures for identifying and isolating instrument malfunctions.

Details procedures for aligning hardware components like probes and optics.

Covers storing and retrieving system data to floppy or hard disks.

Overview of instrument status monitoring and commands.

Covers checking and replacing dilution segments.

Describes how to monitor sample status using colored indicators.

Explains how to access and interpret instrument parameters.

Details accessing commands like Stop, Home, Pause, and Run.

Explains how instrument codes represent chemistry and conditions on reports.

Lists the codes assigned to various chemistries.

Provides the codes used to represent specific conditions on reports.

Introduces examples of reports generated by the IMMAGE 800 system.

Lists the types of reports that can be generated by the system.

Defines alphanumeric characters as A-Z, a-z, 0-9.

Defines an analyte as the component being measured in a test.

Defines antibody as a protein protecting against foreign substances.

Defines antigen as a foreign substance triggering an immune response.

Defines AGXS testing as a test for unbound antibody after antigen reaction.

Defines an assay as a test for a single concentration determination.

Defines assigned mean as the mean value defined for a control.

Defines ASTM protocol as a standardized computer interface specification.

Describes the card containing reagent or calibrator parameters for lot information.

Defines the instrument device that scans and decodes bar codes.

Defines batch as a group of samples with identical programming, except Sample ID.

| Type | Immunochemistry Analyzer |

|---|---|

| Sample Type | Serum, Plasma, Urine, CSF |

| Sample Capacity | Up to 120 samples |

| Power Requirements | 100-240 V AC, 50/60 Hz |

| Detection Method | Nephelometry |

| Assay Methodology | Rate |

| Test Menu | Specific Proteins |

| Reagent Capacity | 44 reagent positions |