26

86107 BA-en/01

English

⋅

Fornax

®

T

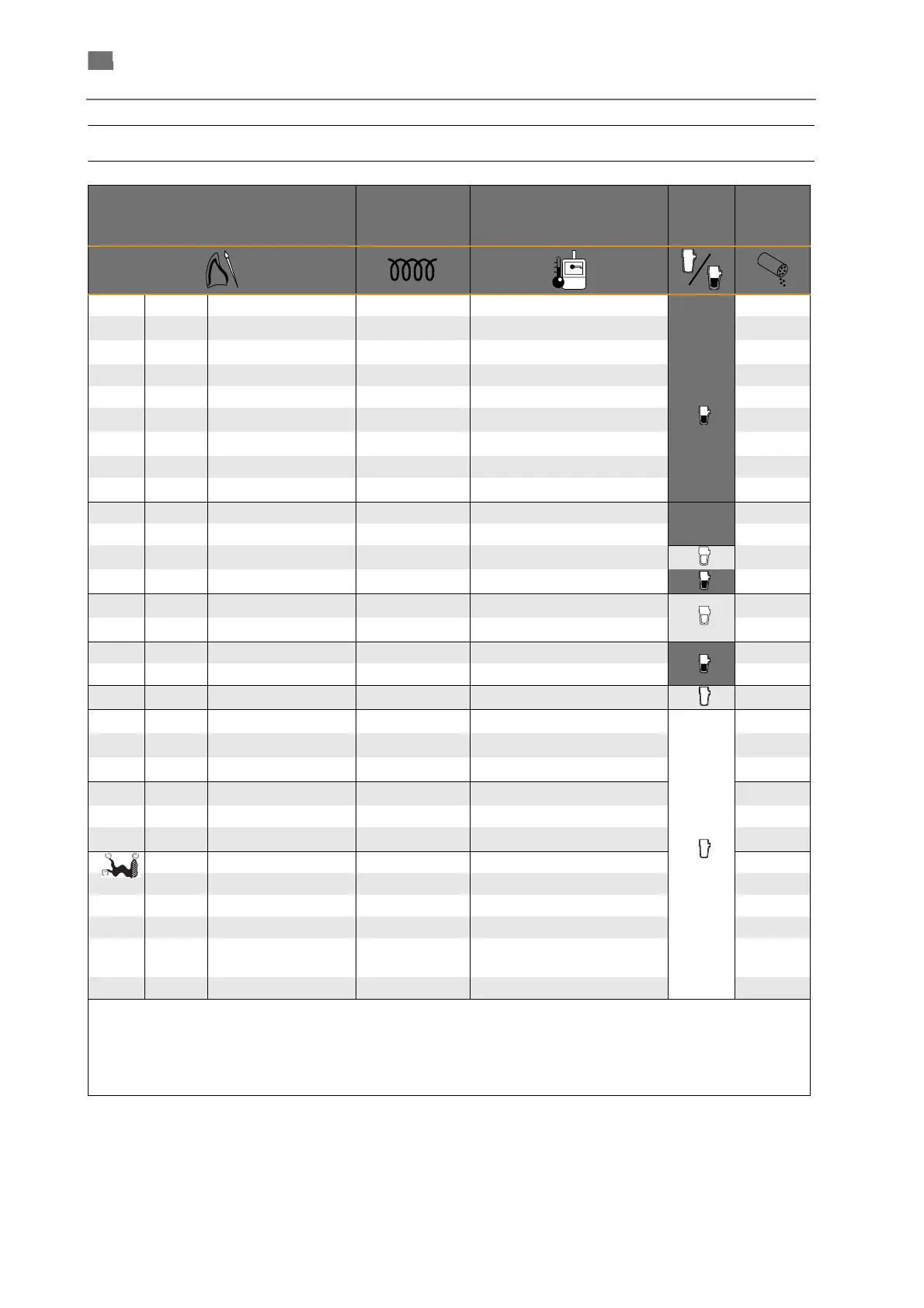

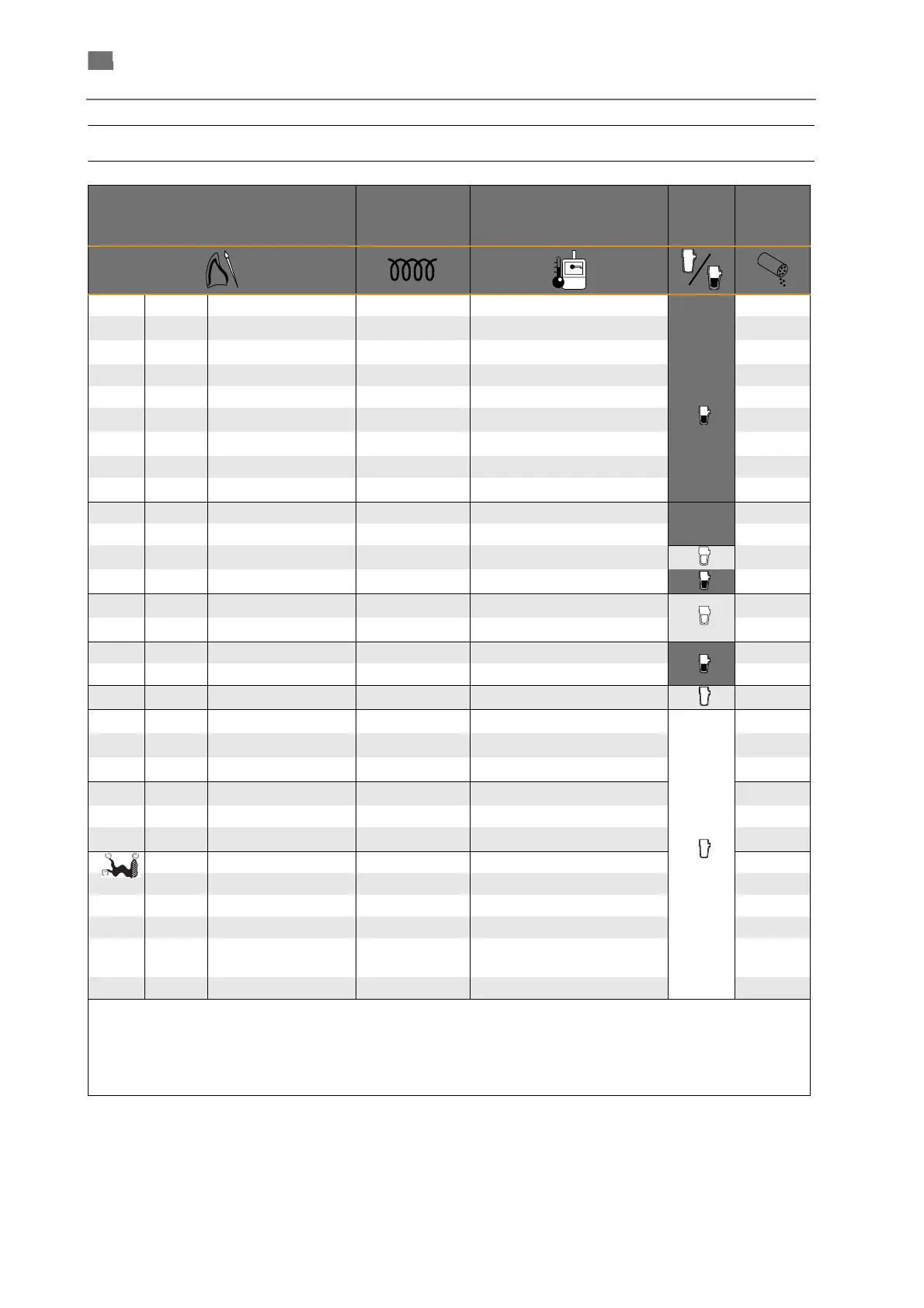

Casting table

Alloys

Continuous

heating /

holding time*

Preheating temperatures

Crucible

and

insert

Melting

powder

Au LFC BioPlatinLloyd

®

14...17 sec 700 °C (1290 °F) -- Auromelt

✔

BioPontoStar

®

15...18 sec 850 °C (1530 °F)

✔

BioPontoStar

®

XL 17...22 sec 850 °C (1530 °F)

LFC PlatinLloyd

®

KF 10...13 sec 700 - 750 °C (1290 - 1380 °F)

- PlatinLloyd

®

M/100 10...13 sec 700 °C (1290 °F)

✔

PontoLloyd

®

G 22...25 sec 850 °C (1530 °F)

✔

PontoLloyd

®

P 18...22 sec 850 °C (1530 °F)

LFC Pontonorm 12...15 sec 700 °C (1290 °F)

✔

PontoStar

®

G/H 17...20 sec 850 °C (1530 °F)

Au LFC AuroLloyd

®

KF 17...20 sec 700 °C (1290 °F)

- AuroLloyd

®

M 17...20 sec 700 °C (1290 °F)

✔

BegoCer

®

G 12...18 sec 850 - 950 °C (1530 - 1740 °F) -- Auromelt

✔

BegoStar

®

22...25 sec 850 °C (1530 °F)

Pd

✔

BegoPal

®

/S 13...16 sec 850 °C (1530 °F) -- Auromelt

✔

BegoPal

®

300 13...16 sec 850 - 950 °C (1530 - 1740 °F) -- Auromelt

Ag LFC BegoStar

®

LFC 17...20 sec 700 °C (1290 °F) -- Auromelt

LFC ECO d’OR 17...20 sec 700 °C (1290 °F)

Eco

✔

BegoStar

®

ECO 07...11 sec 850 °C (1530 °F) -- Auromelt

NiCr

✔

Wirocer plus 06...12 sec 900 - 950 °C (1650 - 1740 °F)

✔

Wiron

®

99 07...10 sec 900 - 950 °C (1650 - 1740 °F)

✔

Wiron

®

light 03...07 sec 800 °C (1472 °F)

CoCr

✔

Wirobond

®

C 07...10 sec 900 - 1000 °C (1650 - 1830 °F)

LFC Wirobond

®

LFC 04...08 sec 900 - 1000 °C (1650 - 1830 °F)

✔

Wirobond

®

SG/280 02...04 sec 900 - 1000 °C (1650 - 1830 °F)

- Wironit

®

07...10 sec 950 - 1050 °C (1740 - 1920 °F)

- Wironit

®

LA 06...08 sec 950 - 1050 °C (1740 - 1920 °F)

Wironit

®

extra-hard 02...10 sec 950 - 1050 °C (1740 - 1920 °F)

- WIRONIUM

®

02...04 sec 950 - 1050 °C (1740 - 1920 °F)

- WIRONIUM

®

extra-

hard

06...08 sec 950 - 1050 °C (1740 - 1920 °F)

- WIRONIUM

®

plus 06...08 sec 950 - 1050 °C (1740 - 1920 °F)

* The determined continuous heating times correspond with our technical process experience with castings using

exclusively new materials and are provided as recommendations. The specified values may deviate depending on

the specific alloys, in particular when using non-BEGO alloys.

Note: The table on the following page is provided to record individually determined continuous heating times.

** A glassy-carbon insert may be used as an alternative to the ceramic insert.

Loading...

Loading...