26

86105 BA-en/00

English ⋅ Nautilus

®

CC plus ⋅ Nautilus

®

T

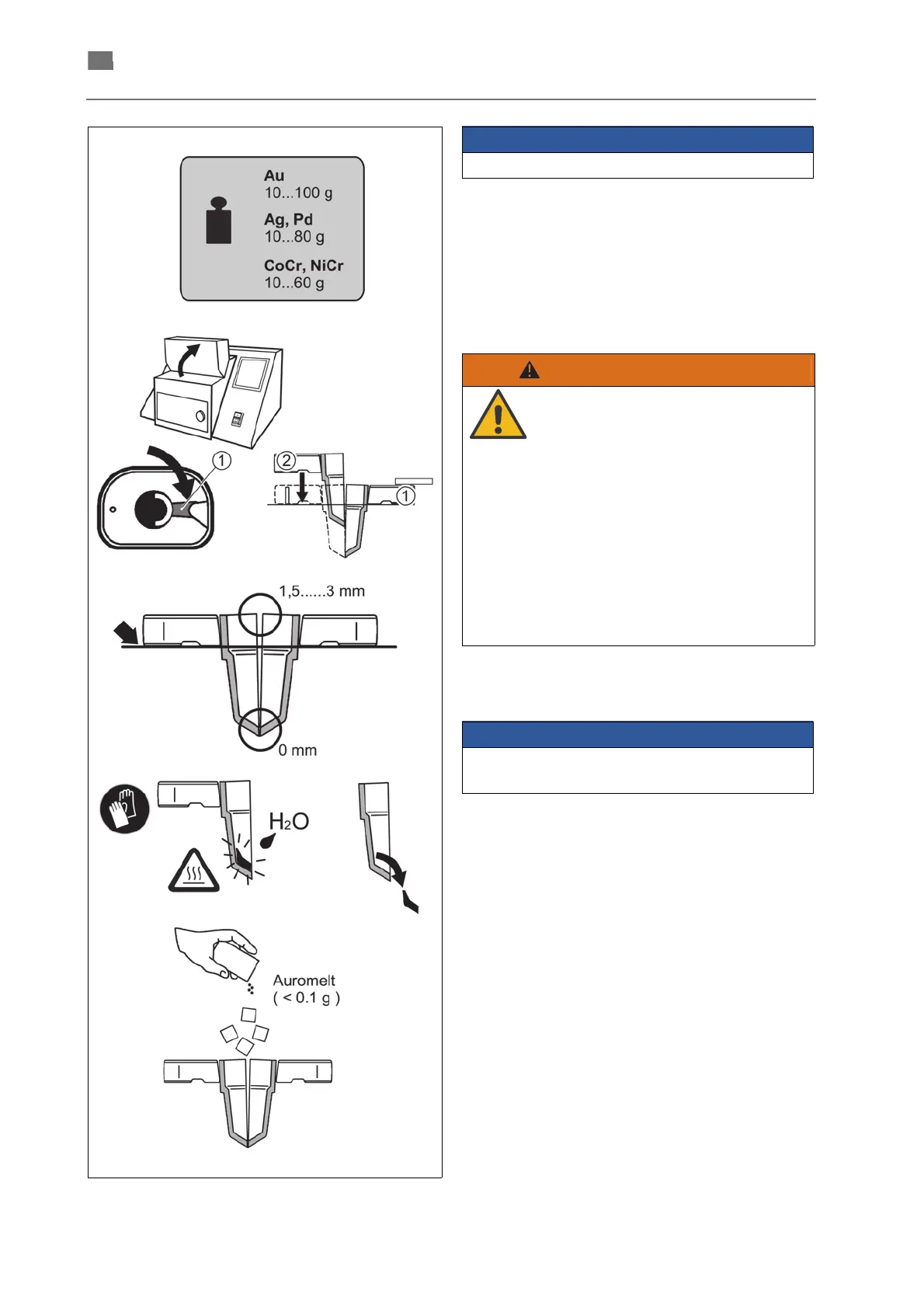

Insert both crucible halves.

(*): Uneven crucible tips that do not close can be

smoothed out by pulling them over fine sandpaper

(grit size ≥ 80).

For special alloys, sprinkle a pinch of BEGO

Auromelt HF melting powder on the alloy (see

program table on page 34).

Melting powder made by other manufacturers may

impair the casting result!

Observe minimum and maximum quantities!

ATTENTION (check before every

casting process)

• The handles must lie on the base

surface.

• The crucible halves must close/seal

on the bottom (*) and leave a gap

between 1.5 to 3 mm at the top.

• Do not use damaged crucible

halves.

• CoCr / NiCr only: do not use crucible

halves with alloy residue on the bot-

tom.

Alloy residues can be easily removed if a drop of

water is added while they are hot.

Loading...

Loading...