5. Chemical Resistance

5.1. Touch Screen and Overlay Material

5.1.1. Protective Film

The Autoflex protective film covers the overlay surrounding the screen.

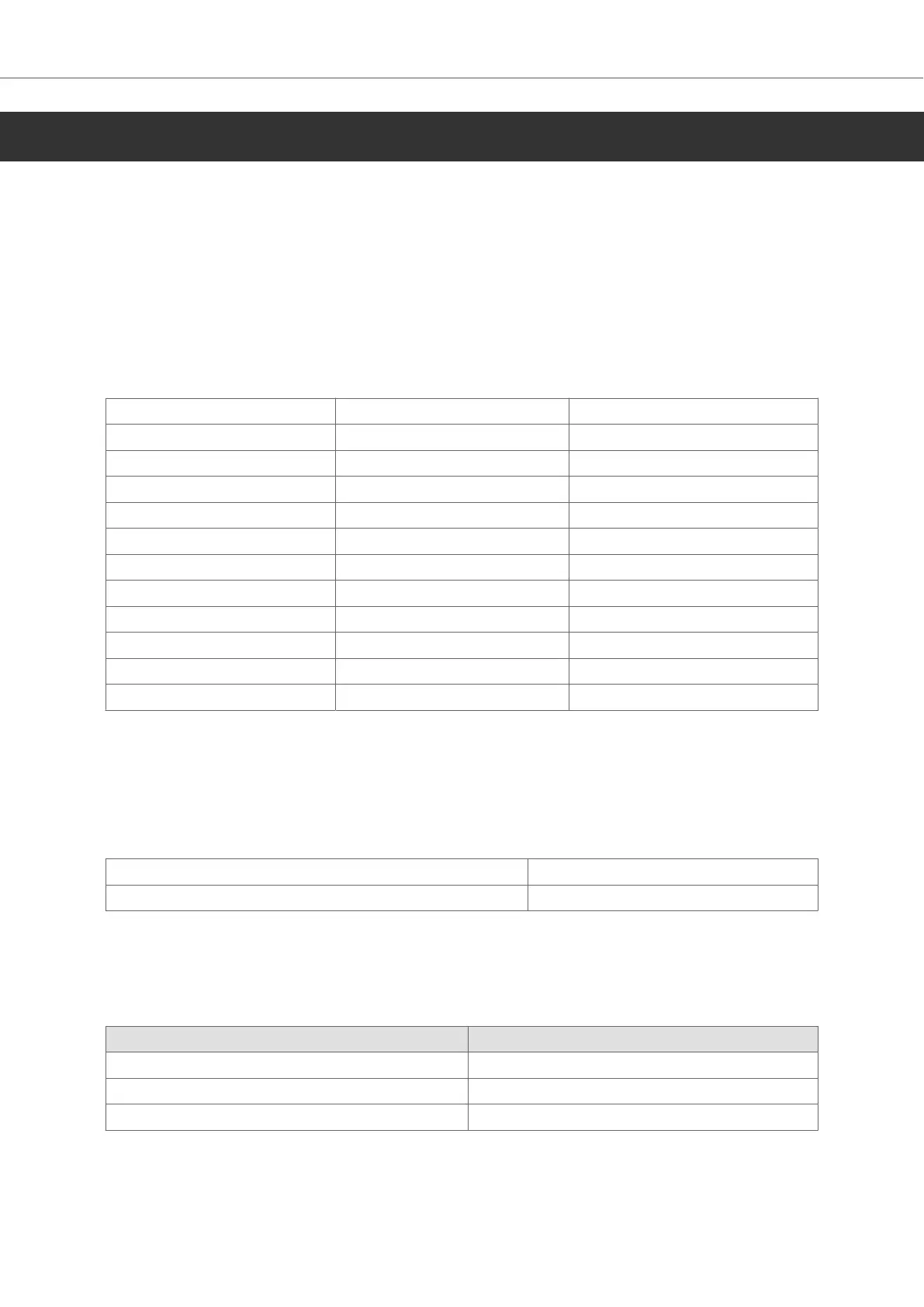

Solvent Resistance

The protective film withstands exposure of more than 24 hours duration under DIN 42115 Part 2 to

the following chemicals without visible change:

Acetonitrile Diesel Petroleum spirit

1

Ajax / Vim in solution Downy / Lenor

1

Phosphoric acid (<30%)

Alkalicarbonate solution

1

Ethanol Potassium ferricyanide

Ammonia (<40%)

1

Glycerine Potassium hydroxide (<30%)

Acetic acid (<50%) Glycol Pure Turpentine

Ariel powder in solution

1

Gumption

1

SBP 60/95

1

Bleach

1

Hydrochloric acid (<36%) Sulfuric acid (<10%)

Castor oil Linseed oil Tomato ketchup

Caustic soda (<40%)

1

Methanol Trichloroacetic acid (<50%)

Cutting oil Nitric acid (<10%) White Spirit

Cyclohexanol Paraffin oil Windex

1

Diacetone alcohol Persil powder in solution

1

Wisk

1

Extremely faint glossing of the texture was noted.

The Autoflex protective film withstands DIN 42 115 Part 2 exposure of up to 1 hour duration to glacial

acetic acid without visible change.

The Autoflex protective film is not resistant to high pressure steam at over 100°C or the following

chemicals:

Concentrated mineral acids Benzyl alcohol

Concentrated caustic solution Methylene chloride

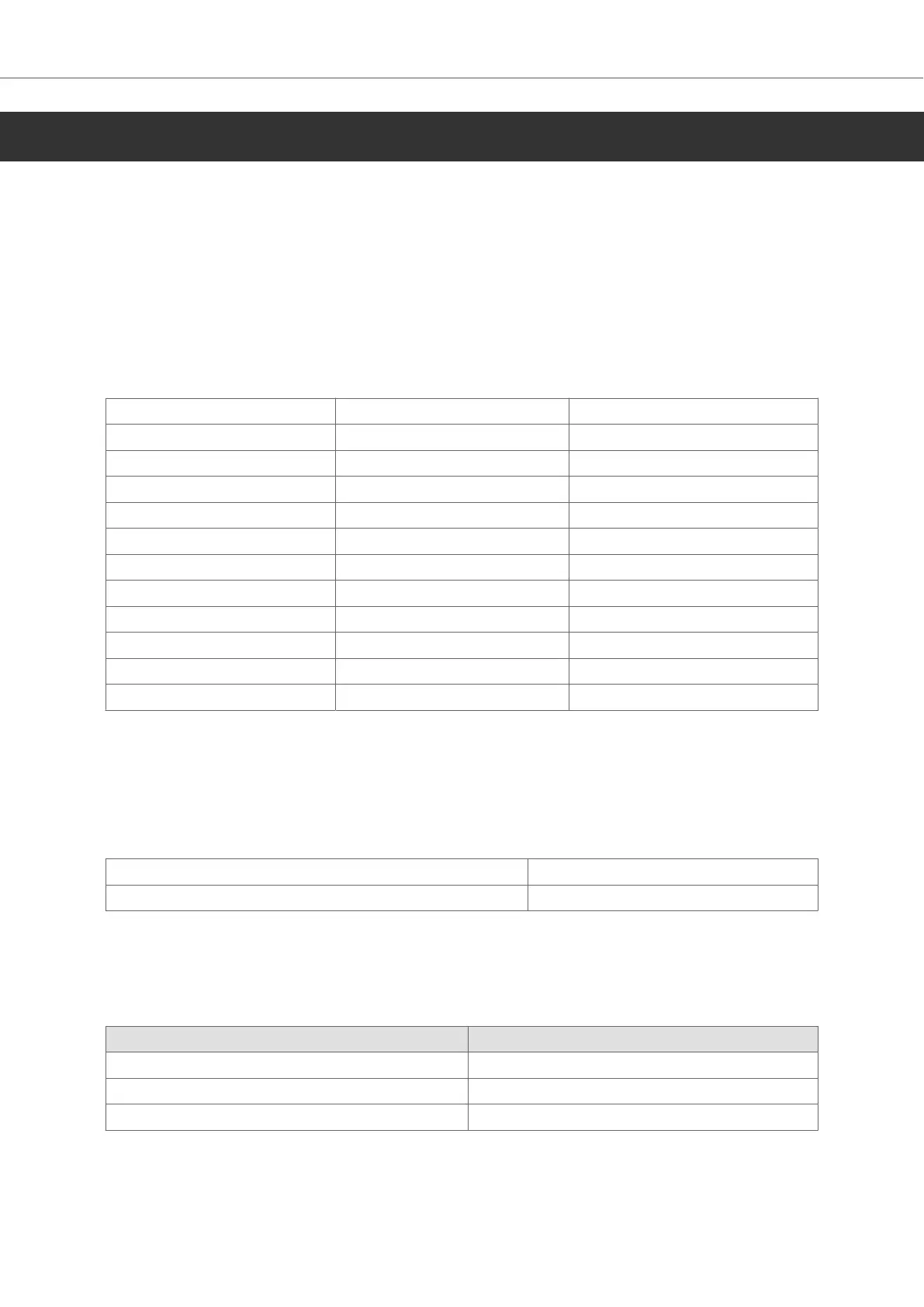

5.1.2. Touch Screen Surface

The touch screen surface on the HMI panel withstands exposure to the following solvents without

visible change:

Solvents Time

Acetone 10 minutes

Isopropanol 10 minutes

Toluene 5 hours

The touch screen surface on the HMI panel is made of polyester with a hard coat to resist scratches

and withstand exposure to many solvents without visible change.

Chemical Resistance

2023-09 16 Beijer Electronics, MAEN330

Loading...

Loading...