6/16 - Subject to change. © Belimo Aircontrols

USA

, Inc

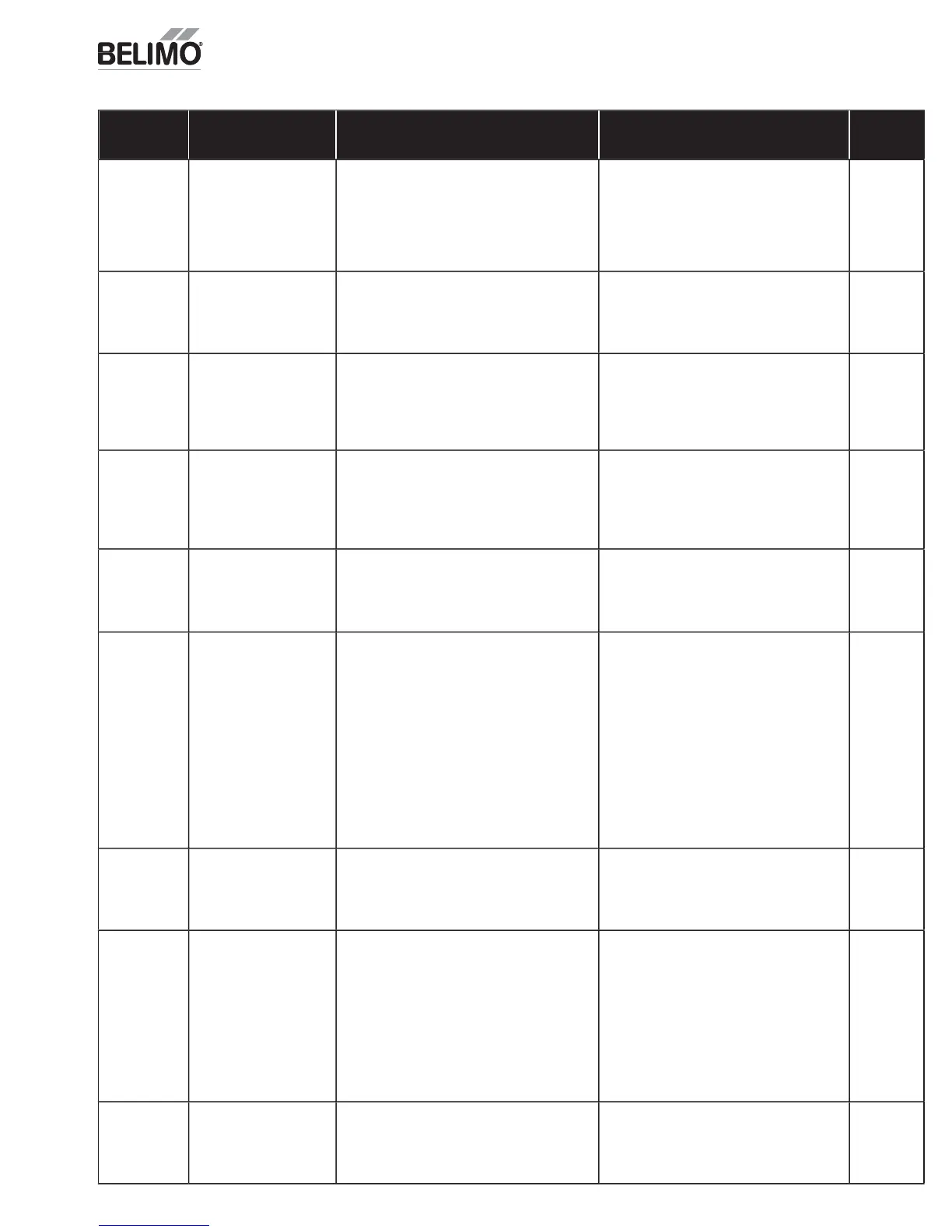

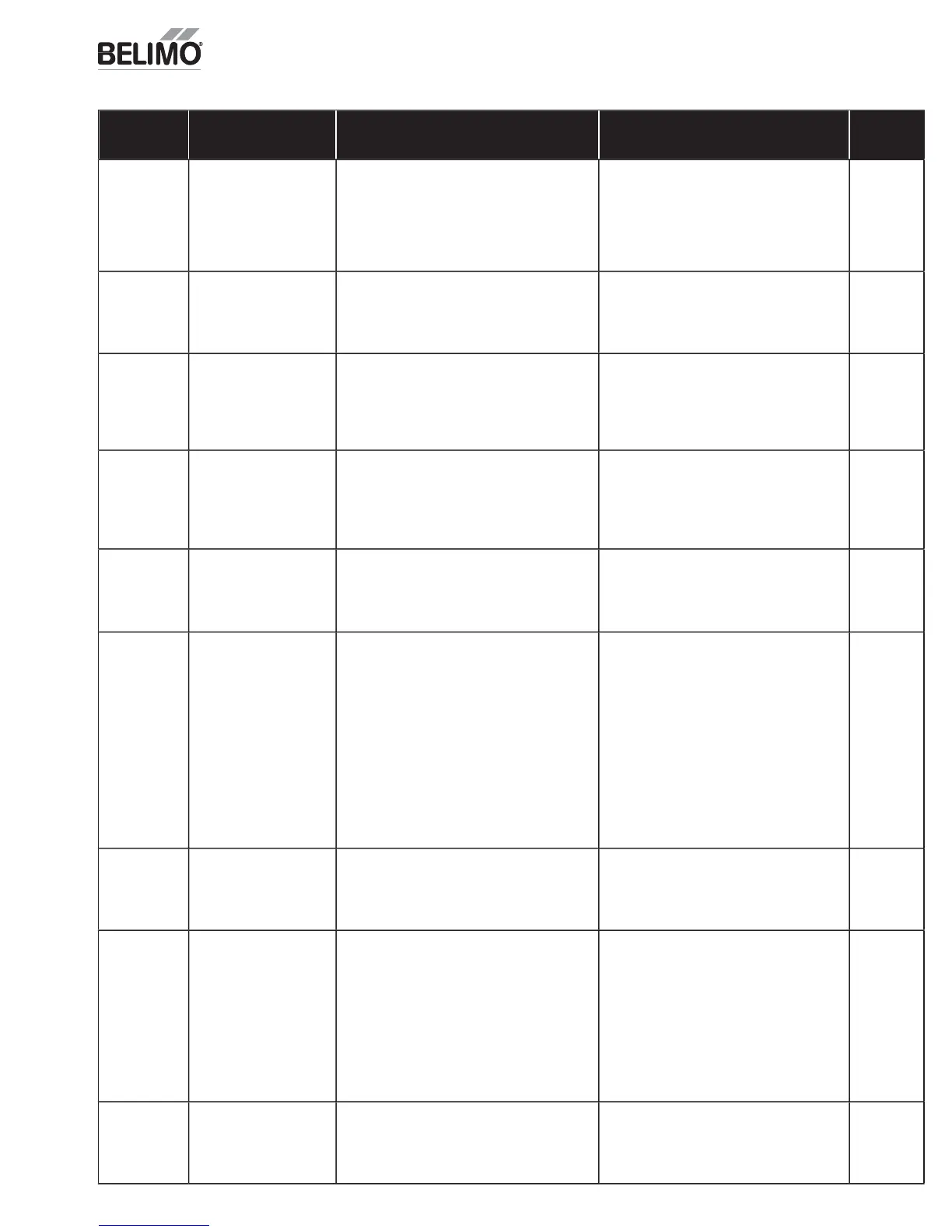

Fault Detection Problem

Diagnostic Action

(in addition to alarm stored / transmitted)

Potential Cause

CA Fault

Code

RAH sensor

detected but

AH

n

r

not

etecte

ensor previousl

nstalled

s not detected

r

n

r h

n

t

n

nstalled -

i

erential Enthalpy

• Economizing functioning b

differential

temperature with return air humidit

limi

• Intended con

gurat

on o

d

erent

al enthalp

ot completed or OAH sensor faile

• Intended con

gurat

on o

s

ngle enthalp

,

AH sensor inadvertentl

placed on RAH

erm

na

•

AH sensor deleted or set to not installed, but

AH sensor left installe

, B

RAH sensor

etecte

ut

RAT sensor

not detected

ensor previously

nstalled

s not detected

r sensor

as not

een

n

t

ll

-

ifferential Enthal

• Economizing functioning b

OAE single enthalp

•

han

e over limit modified to 28 Btu

lb 75°

• Intended con

gurat

on o

d

erent

al enthalp

ot com

leted or RAT sensor faile

• RAT sensor deleted, but RAH sensor le

t

nstalle

,

AT

n

r

out of ran

e

ensor is returning a

v

l

th

t

t

th

predetermined ran

e

• Economizing functionalit

disabled

• Freeze detection based on

AT onl

• Low d

scharge l

m

t control 45°F d

sable

• Compressor SAT drop error detection disable

• Limitin

2nd sta

e operation based on low SAT

SAT Y2 limit

disabled

• Th

rm

t

r

l

r

• Damage to wire increasing resistance

B

AT

n

r

not detected

ensor previousl

n

t

ll

n

t

t

t

r sensor has not been

n

t

ll

• Economizing functionalit

disabled

• Freeze detection based on

AT onl

• Low d

scharge l

m

t control 45°F d

sable

• Compressor SAT drop error detection disable

• Limitin

2nd sta

e operation based on low SAT

SAT Y2 limit

disabled

• Sensor never installe

• Installed sensor has o

en or short

• W

r

h

rn

r

k

n

B

Y2

resent

w

thout Y1

ll f

r Y2 with

t

ll

or Y1

• Enable 1st sta

e

ree cool

n

or mechan

cal

coolin

in accordance chan

e over

con

gurat

o

• I

Y1

ollows Y2, 2nd sta

e

nte

rated or

mechan

cal cool

n

w

ll be enable

• Miswired or reverse wired thermostat

• Mi

wir

ZIP E

n

miz

• Thermostat

a

lur

• W

re harness broken

N/A

SAT drop for

CC1 or CC2

nsu

c

en

AT sensor determined

t

at temperature

ownstream o

vaporator d

d not drop

b

at least 5°F a

ter 4

in of CC1 or CC2 bein

ner

ze

• In

ormat

onal onl

- no act

on

• F

lters or co

ls are d

rt

or blocked –

nspect

• SAT sensor in a location where it is not mixed

perform temperature travers

• Indoor fan is ino

erable -

heck rela

, belt, motor, bearing

• Condenser fan is inoperable -

heck rela

, motor, head pressure control

•

ompressor is fault

(internal damage) -

ec

amperage, pressures

• Contactor ener

izes but compressor is off on

nt

rn

l

xt

rn

l

v

rl

• Hi

h volta

e problem to compressor -

heck wirin

, phases, contacto

• Low on refri

erant - check char

e

N/A

Dam

er Pos

value m

ss

n

E

n

m

z

r

n

t

sens

n

eedback

rom

r

• Lo

c recon

ured to use setpo

nt as re

erence

or

tems de

endent on actual

os

t

on

.e.

nte

rated cool

n

• Damper stuck

ault detect

on capab

l

t

s

l

• Actuator w

res not properl

term

nated

• Actuator w

thout

eedback capab

l

t

use

• W

r

h

rn

r

k

n

• A

t

t

r

l

tr

n

l

r

AT

h

l

e

owe

hen damper is

reater

than 85% o

en, and in

ree coolin

, SAT sensor

eterm

ned that

temperature

s not w

th

n

10°F of OA

• In

ormat

onal onl

- no act

on

• Damper l

nka

e

a

lur

• Actuator clamp

interface between damper

n

t

r

• Damper blades are not secured to damper

shaft properl

• Outside air dam

er and return dam

er do not

stro

e proper

• Return damper does not closes t

ghtl

when

utdoor damper

s

ull ope

•

AT sensor is poorl

located

• SAT sensor is poorl

locate

B

Damper

s

stuc

Feedback s

gnal

s not

w

th

n range o

ommanded pos

t

on

• I

rotat

on

s less than 85%, then

ntegrated

cool

ng w

ll be d

sable

• Damper linkage failur

• Damper blocked w

th

ore

gn ob

ect

• Actuator l

m

t stop engage

• Damper rotat

on has not been scaled us

ng

conom

zer Acceptance Test

B,

, D, E

n

m

z

ault Detection and Diagnostics

FDD

Tabl

Loading...

Loading...