Wiring Diagrams

LMB(X)24-MFT - Typical Specification:

Proportional control damper actuators shall be electronic

direct-coupled type, which require no crankarm and linkage

and be capable of direct mounting to a shaft from 1/4” to 5/8”.

Actuators must provide control in response to a control input

from an electronic controller or positioner. Actuators shall have

Brushless DC motor technology and be protected from over-

load at all angles of rotation. Actuators shall have reversing

switch and manual override on the cover. Run time shall be

constant and independent of torque. Actuators shall be cULus

listed, have a 5-year warranty, and be manufactured under

ISO 9001 International Quality Control Standards. Actuators

shall be as manufactured by Belimo.

LMB (X) 24-MFT

Proportional Control, Non-Spring Return, Direct Coupled, 24V, Multi-Function Technology

®

Accessories

K-LM20 3/4” [20 mm] Shaft Clamp

AV6-20 Shaft Extension

ZG-LMSA Shaft Adaptor for 1/2” Diameter Shafts

ZG-LMSA-1 Shaft Adaptor for 3/8” Diameter Shafts

ZS-100 Weather Shield - Steel

ZS-150 Weather Shield - Polycarbonate

Tool-06 8 mm & 10 mm Wrench

S1A, S2A Auxiliary Switch (es)

P370 Shaft Mount Auxiliary Switch

P…A Feedback Potentiometers

SGA24 Min positioners in NEMA 4 housing

SGF24 Min positioners for flush panel mounting

ADS-100 Analog to Digital Switch

ZG-R01 Resistor for 4 to 20 mA Conversion

NSV24 US Battery Back-Up Module

1

2

Provide overload protection and disconnect as required.

Actuators may be connected in parallel if not mechanically mounted

to the same shaft. Power consumption and input impedance must

be observed.

3

Actuators may also be powered by 24 VDC.

Notes:

4

Position feedback cannot be used with a Triac sink controller.

The actuator internal common reference is not compatiable.

5

Control signal may be pulsed from either the Hot (Source)

or Common (Sink) 24 VAC line.

6

ZG-R01 may be used.

7

Contact closures A & B also can be triacs. A & B should

both be closed for triac source and open for triac sink.

8

For triac sink the common connection from the actuator

must be connected to the hot connection of the controller.

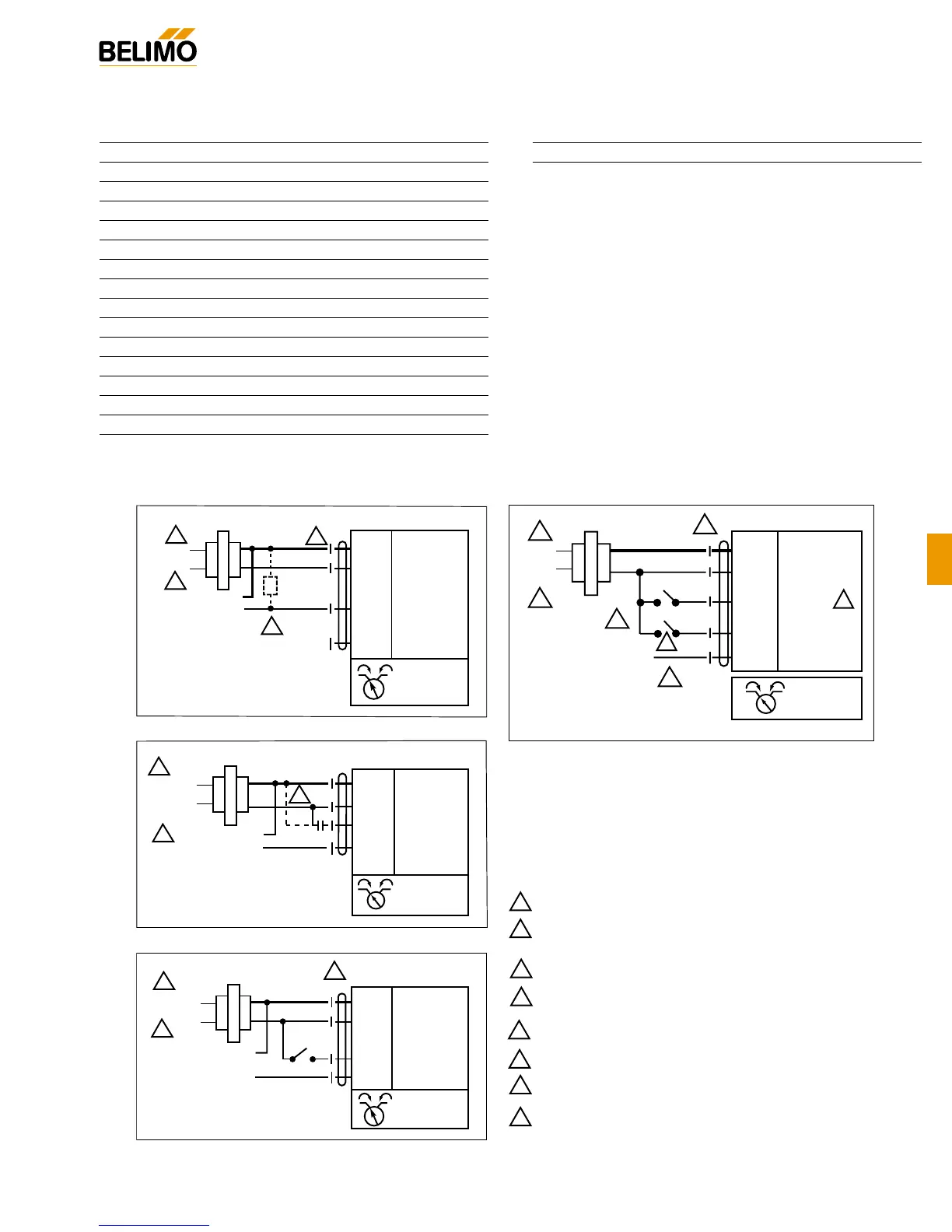

VDC/4-20 mA

6

Blk

(1) Common

Red

(2) + Hot

Wht

(3) Y

1

Input, 2 to 10V

Org (5) U Output, 2 to 10V

4 to 20 mA

or

2 to 10 VDC

Control Signal

Line

Volts

24 VAC Transformer

2

1

3

(+)

(–)

Ω

500Ω

1/4 watt

On/Off

Blk (1) Common

Red

(2) Hot

Wht

(3) Y Input

Org

(5) U Output

Line

Volts

24 VAC/DC Transformer

…MFT

a

Position

Feedback VDC

(+)

(–)

2

1

3

PWM

Blk (1) Common

Red

(2) + Hot

Wht

(3) Y Input

Org

(5) U Output

Line

Volts

24 VAC Transformer (AC only)

(+)

(–)

5

2

…MFT

…MFT

Position

Feedback VDC

1

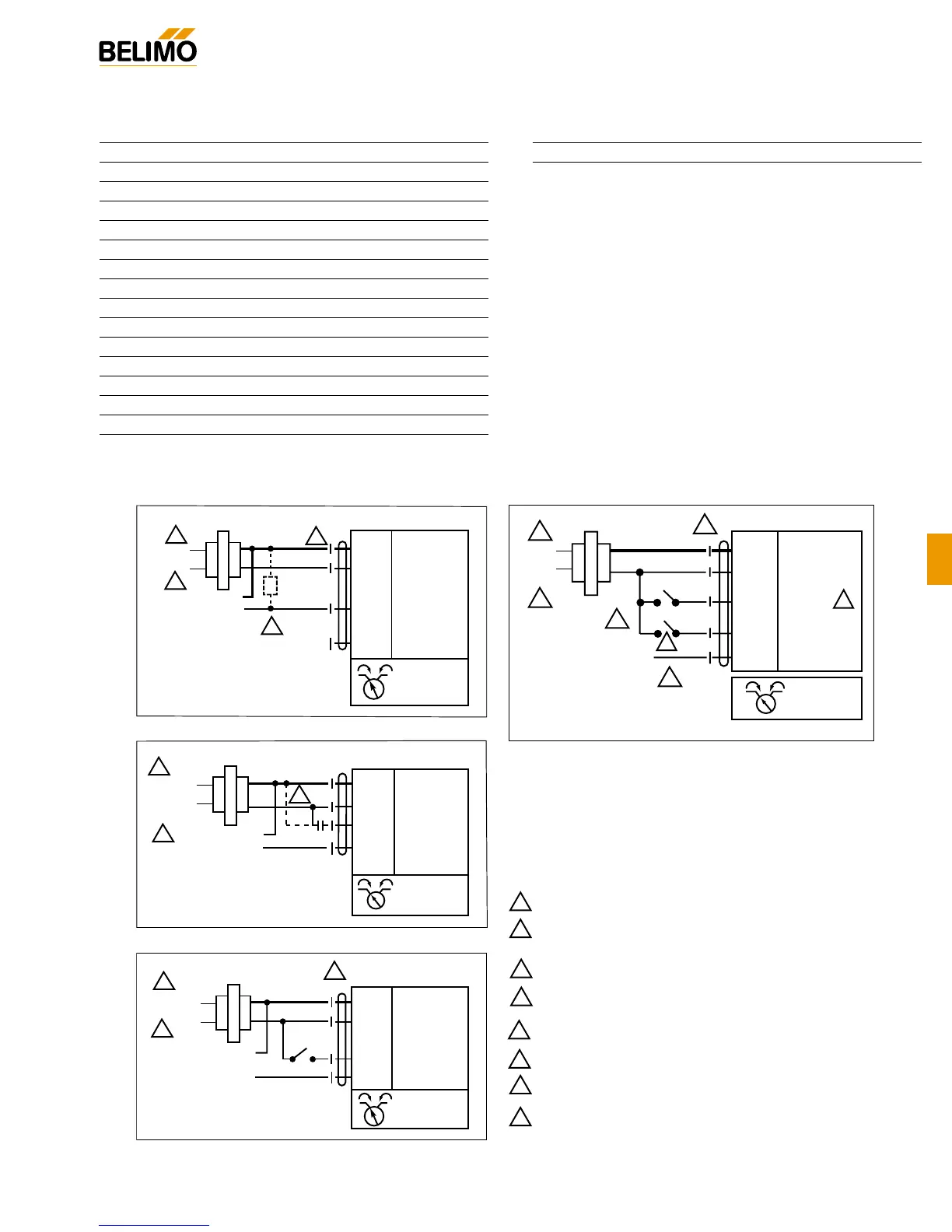

Floating Point

…MFT

Line

Volts

2 to 10 VDC

Feedback Signal

24 VAC Transformer

Blk

(1) Common –

Red

(2) Hot +

Wht

(3) Y

1

Input

Pnk

(4) Y

2

Input

Org (5) U Output 2 to 10V

1

3

5

4

2

A

B

7

8

Loading...

Loading...