218

J20741 - Subject to change. © Belimo Aircontrols (USA), Inc.

Technical Data LMX24-MFT95

Power Supply 24 VAC ± 20% 50/60 Hz

24 VDC ± 10%

Power Consumption 2 W (1.2 W)

Transformer Sizing 3.5 VA (Class 2 power source)

Electrical Connection 18 GA plenum rated cable

1/2” conduit connector

❑ 3 ft [1m] ❑ 10 ft [3m] ❑ 16 ft [5m]

Overload Protection electronic throughout 0 to 95° rotation

Operating Range WRB 0 to 135Ω Honeywell Electronic

Series 90, 0 to 135Ω Input

Input Impedance 100 kΩ (0.1 mA)

Feedback Output U 2 to 10 Vdc, 0.5mA max

VDC Variable

Angle of Rotation max. 95°, adjust. with mechanical

stop electronically variable

Torque 45 in-lb [5 Nm]

Direction of Rotation reversible with switch

Position Indication reflective visual indicator (snap-on)

Manual Override external push button

Running Time 150 seconds (default)

Variable (35 to 150 secs)

Humidity 5 to 95% RH non condensing

(EN 60730-1)

Ambient Temperature -22°F to +122°F [-30°C to +50°C]

Storage Temperature -40°F to +176°F [-40°C to +80°C]

Housing NEMA 2/IP54

Housing Material UL94-5VA

Agency Listings† cULus acc. to UL60730-1A/-2-14,

CAN/CSA E60730-1, CSA C22.2

No. 24-93, CE acc. to 89/336/EEC

Noise Level <35dB(A)

Servicing maintenance free

Quality Standard ISO 9001

Weight 1.5 lbs [0.7 kg]

†Rated Impulse Voltage 800V, Type of action 1,

Control Pollution Degree 3.

LMX24-MFT95

Proportional Control, Non-Spring Return, Direct Coupled, 24V, 0 to 135Ω Input

Torque min. 45 in-lb for control of damper

surfaces up to 11 sq ft.

Application

For proportional modulation of dampers in HVAC systems.

Actuator sizing should be done in accordance with the

damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft from

1/4” up to 5/8” in diameter by means of its universal clamp.

Shafts up to 3/4” diameter can be accommodated by an

accessory clamp.

The default parameters for 0 to 135Ω input applications of the

…MFT95 actuator are assigned during manufacturing. If nec-

essary, custom versions of the actuators can be ordered. The

parameters can be changed by two means: pre-set and cus-

tom configurations from Belimo or on-site configurations using

the Belimo PC-Tool software.

Operation

The actuator is not provided with and does not require any

limit switches, but is electronically protected against overload.

The anti-rotation strap supplied with the actuator will prevent

lateral movement.

The LMX series provides 95° of rotation and a visual indicator

indicates position of the actuator. When reaching the damper

or actuator end position, the actuator automatically stops.

The gears can be manually disengaged with a button on the

actuator cover.

The LMX24-MFT95 actuators use a Brushless DC motor,

which is controlled by an Application Specific Integrated

Circuit (ASIC). The ASIC monitors and controls

the actuator’s rotation and provides a digital rotation sensing

(DRS) function to prevent damage to the actuator in a stall

condition. Power consumption is reduced in holding mode.

Add on auxiliary switches or feedback potentiometers are

easily fastened directly onto the actuator body for signaling

and switching functions

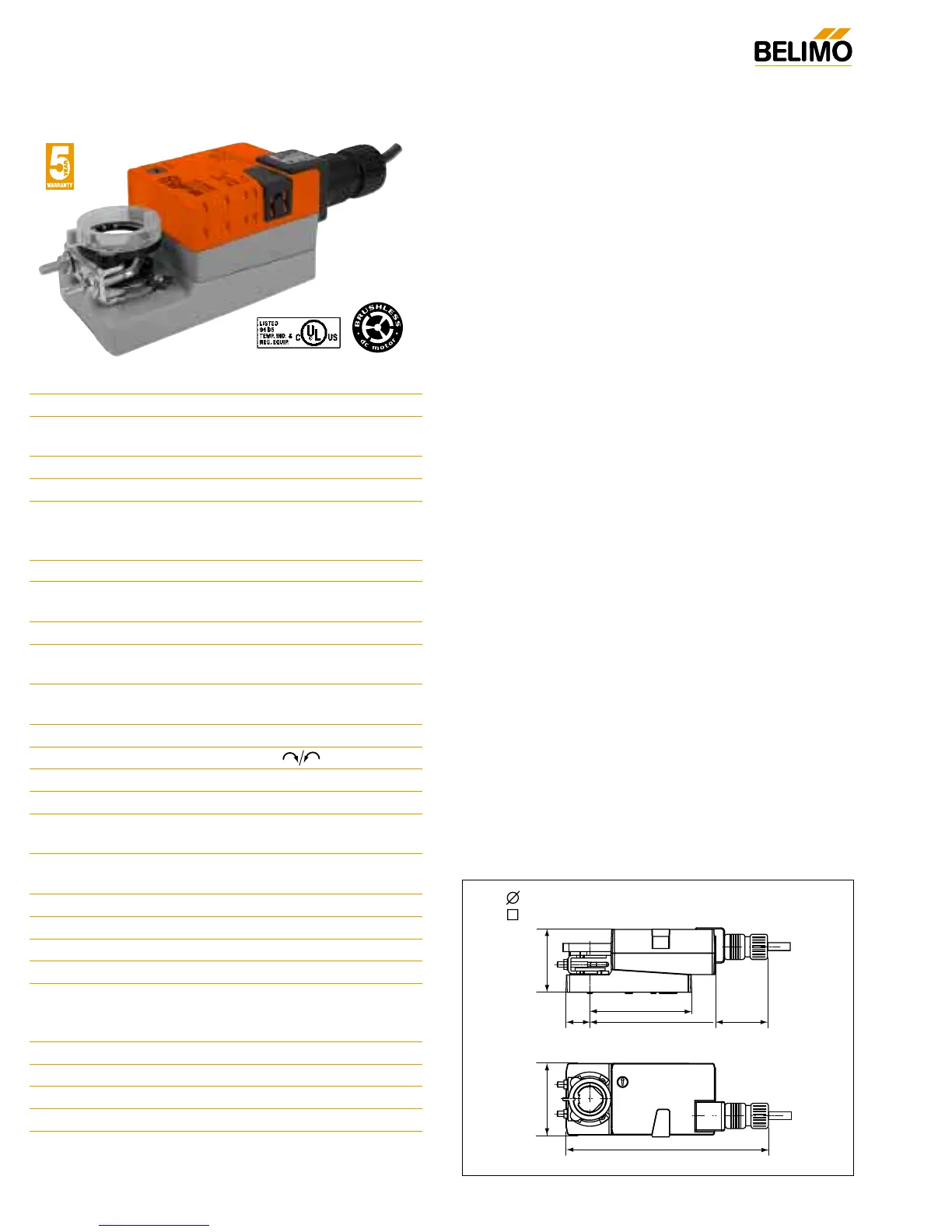

Dimensions

(All numbers in brackets are in millimeters.)

Loading...

Loading...