VRP-M VAV

Ready-to-connect system solution

6 / 28 Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes www.belimo.eu

Commissioning

Prerequisites

– The VAV / CAV unit must be mounted

– The VRP-M system solution must have been set and calibrated for the VAV / CAV unit by the

unit manufacturer

– The electrical connection must have been made and checked

– The 24 V supply and control must be ready for operation

– The system fan must be in operation

Procedure

– Check the electrical connection

– Check the zero offset of the pressure sensor

– Check the damper mobility

– Check the supply pressure (the system fan must be in operation and calibrated)

– Check the

min

/

max

settings and correct them if necessary

– Check the control signal setting and adjust it if necessary

Angle of rotation adaptation

The angle of rotation must be adapted whenever the angle of rotation limiting of the

NMQB24-SRV-ST damper actuator is adjusted.

Procedure:

– Switch on the 24 V supply

– Press the manual override pushbutton twice

The actuator moves into the CLOSED...OPEN...setpoint position

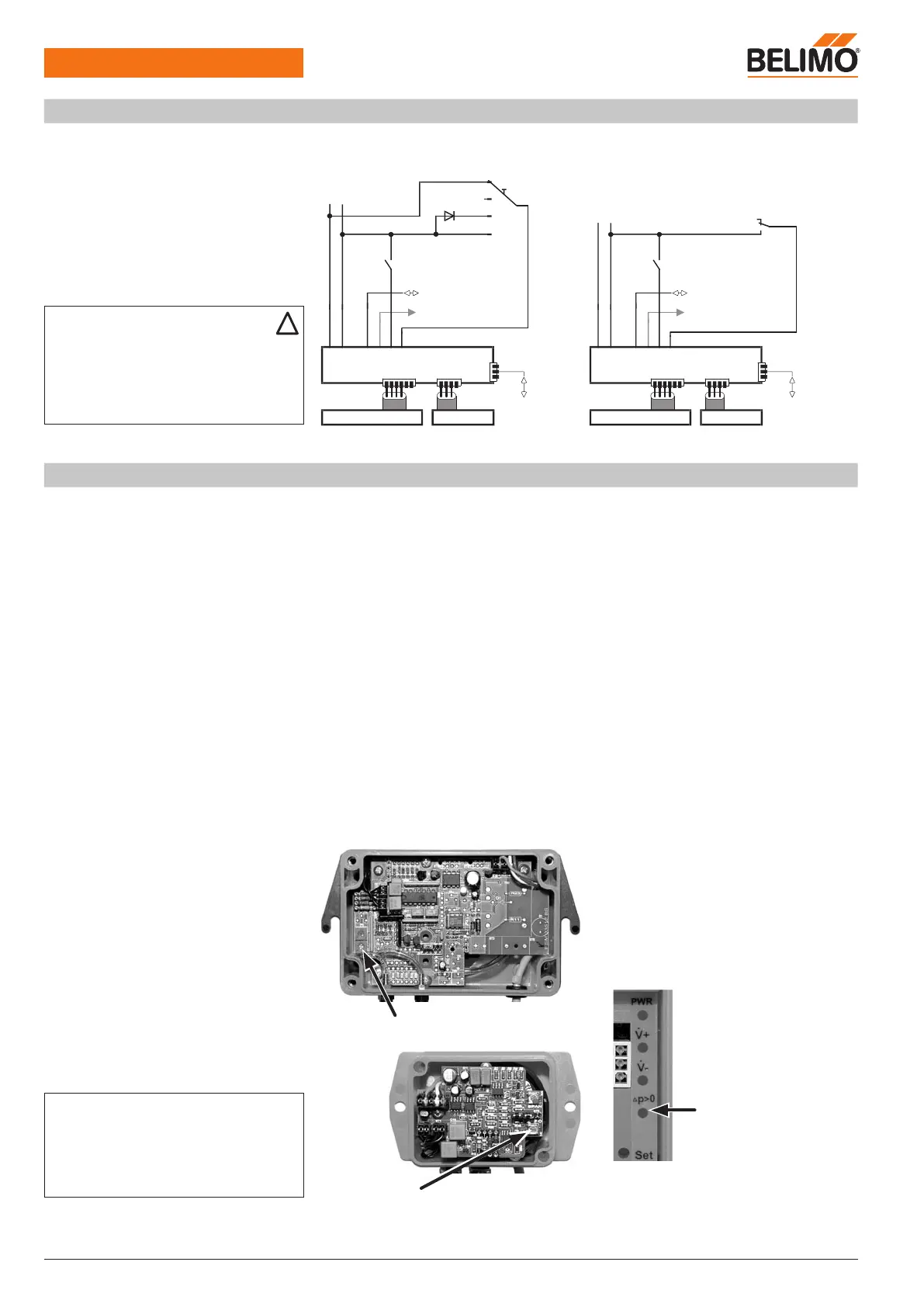

VFP-.. static pressure sensor

Zero offset

– Disconnect both (!) hose connections from the

sensor

– Remove the cover of the VFP-.. sensor

housing

– Turn the zero potentiometer inside the VFP‐..

until the LED in the VRP-M [p>0] lights up

– Turn the zero potentiometer back until the LED

goes out again

Zero potentiometer VFP-100

Note

Fast-running damper actuator NMQB24-SRV-ST

A synchronisation is performed after the power sup

-

ply is switched on or after the manual disengage

-

ment is actuated; this means the actuator moves to

CLOSED and returns to its nominal position.

Zero potentiometer VFP-300

VFP-600

Electrical installation

(Continued)

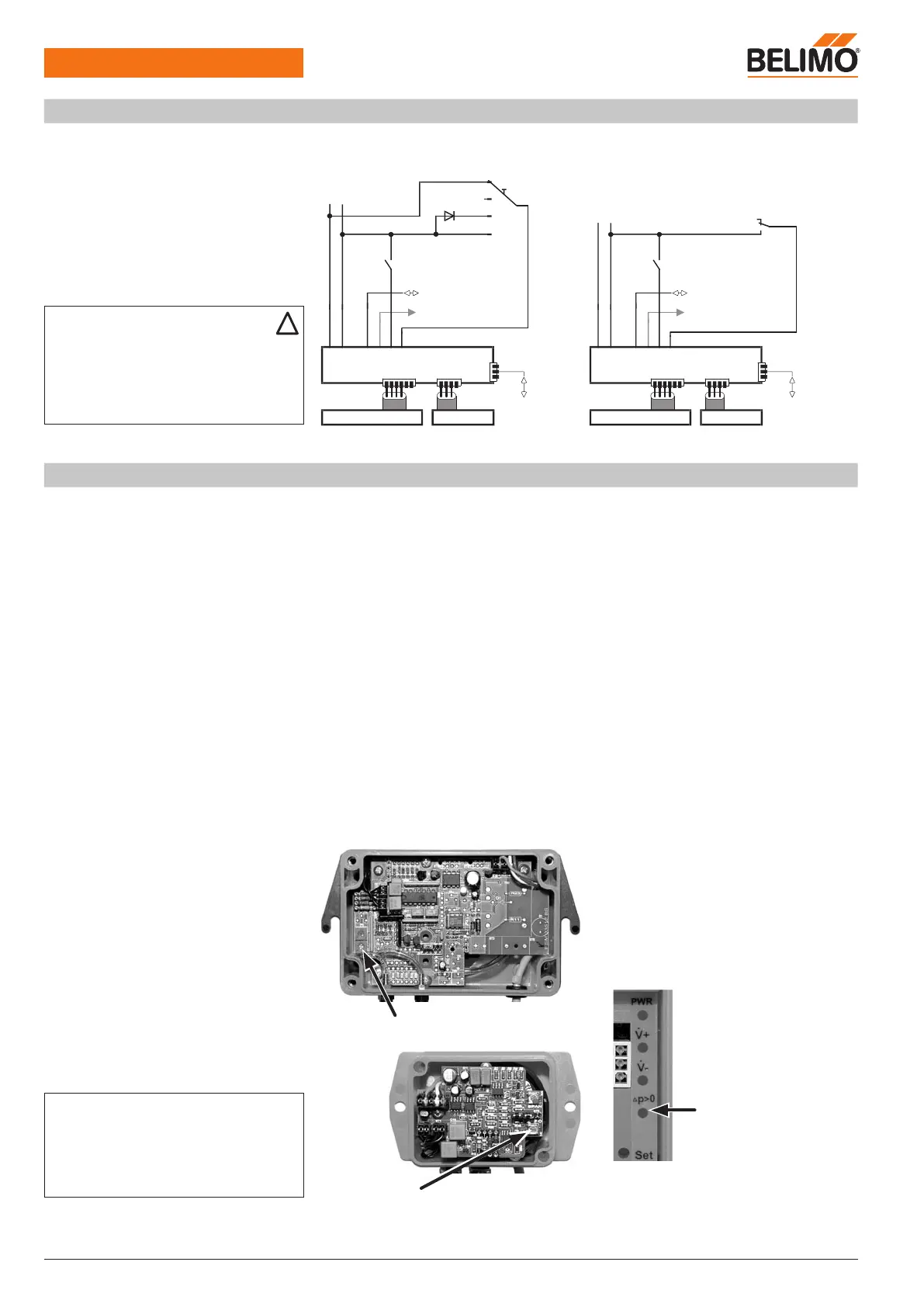

Wiring diagrams: CAV operation Example 1: Example 2:

min

–

max

– OPEN

See pages 10 and 11 for a description of function

Note

– Supply via safety isolation transformer!

– We recommend routing connections 1, 2

(AC/DC 24 V), 4 (MP signal) and 5 (U5 signal)

to accessible terminals (floor distributor, control

cabinet, etc.), in order to simplify access with the

VRP-M-Tool for diagnostic and service work.

Loading...

Loading...