Technical data sheet NM24A-V-ST actuator

www.belimo.eu Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes 23 / 28

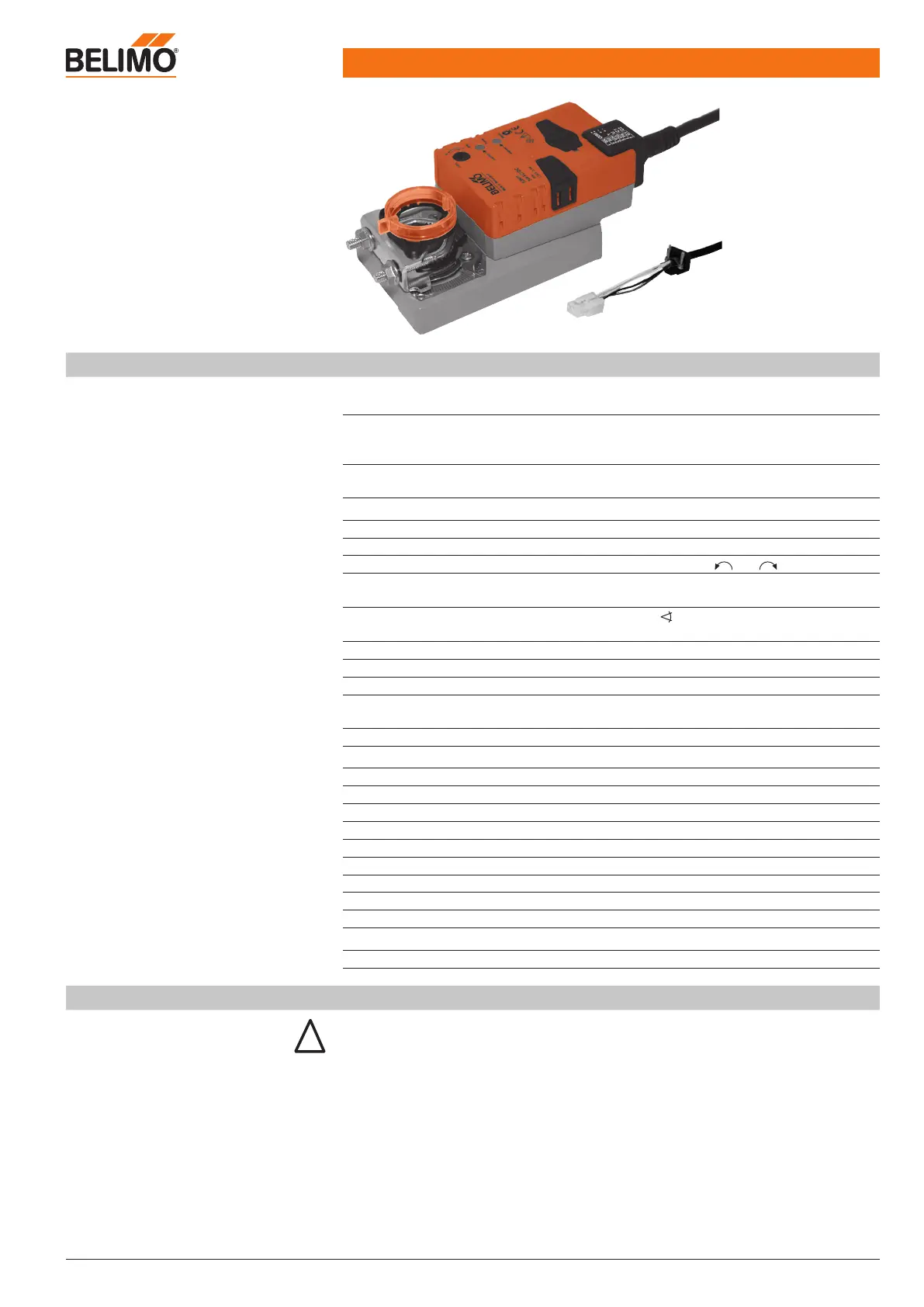

Damper actuator

for VRP-M system solution

Technical data

Electrical data

Nominal voltage AC 24 V, 50/60 Hz / DC 24 V

(from VR.. controller)

Power consumption In operation

At rest

For wire sizing

3.5 W @ nominal torque

1.25 W

5.5 VA

Connection 0.5 m cable with 6-pin plug

(compatible with VRP-M)

Functional data

Torque (nominal torque) Min. 10 Nm @ nominal voltage

Uni-rotation ±5%

Direction of rotation Can be selected with 0 / 1 switch

Direction of motion at Y = 2 V In switch position 0 or 1

Manual override Disengaging the gearing latch by means

of a pushbutton, self-resetting

Angle of rotation

Max. 95° , can be limited at both ends

with adjustable mechanical end stops

Running time 150 s

Sound power level Max. 35 dB (A)

Position indication Mechanical, plug-on

Adaptation Adaptation of the control range

to the damper angle of rotation

Display LED display for 24 V supply and states

Safety

Protection class III Safety extra-low voltage

Degree of protection IP54 in all mounting positions

EMC CE according to 89/336/EEC

Mode of operation Type 1 (in acc. with EN 60730-1)

Rated impulse voltage 0.8 kV (in acc. with EN 60730-1)

Control pollution degree 3 (in acc. with EN 60730-1)

Ambient temperature range –30 ... +50°C

Non-operating temperature range –40 ... +80°C

Ambient humidity range 95% RH, non-condensating (EN 60730-1)

Maintenance Maintenance-free

Dimensions/weight

Dimensions See «Dimensions» on page 25

Weight Approx. 710 g

Safety notes

• The damper actuator is not allowed to be used outside the specified field of application,

especially in aircraft or in any other airborne means of transport.

• It may only be installed by suitably trained personnel.

All applicable legal or institutional installation regulations must be complied with.

• The device may only be opened at the manufacturer‘s site. It does not contain any parts that

can be replaced or repaired by the user.

• The cable is not allowed to be removed from the unit.

• When the required torque is calculated, the cross section, design and installation site as

well as the air flow conditions must be observed.

Loading...

Loading...