OPERATION

OPERATING INSTRUCTIONS

BinLoweringProcedureAfter

Engine/Pump Failure

Emergency bin lowering will be required in the case

when there is a major machine failure where the bin

cannot be lowered by the normal operator bin function

controls.

Inspect the terrain and surrounding areas where the

machine has failed to establish if it is safe to continue

with this procedure.

Ensure there are no overhead lines that might

interfere with the bin movement.

Ensure people and other processes or operations are

clear from the machine when commencing with the

emergency bin lowering.

If possible, engage the artic lock.

Always ensure that cab is not in the raised position

when lowering the bin. It could be required in this

procedure that the cab needs to be raised.

Do not loosen any hoses, connectors or fittings

unless the emergency bin lowering procedure

indicates otherwise.

Tools and Equipment Required

• 18 mm spanners (to loosen the cab bolts)

• 30 mm spanner

• 5 mm Allen key

• Hydraulic hand Pump

Procedure:

1. Inspect and examine the machine and the sur-

rounding area where the machine has failed to

determine if it is safe to commence with the

emergency bin lowering. Ensure nothing will in-

terfere with the bin movement when lowering

the bin. Ensure all people are cleared from the

machineandbinarea.

2. Install the artic lock if possible and place wheel

chocks on two wheel sets either side of the ma-

chine. Also ensure the cab is not in the raised

position when commencing with step 7 of this

procedure.

3. If the bin is stuck in a position where the tip cyl-

inders are not fully extended and the bin is not

over centre on the bin pivots, steps 4 to 5 of this

procedure could be left out and proceed with

step 6. If the tip cylinders are fully extended and

the bin is over the centre of the pivot points, a

hand pump will be required to assist with the

lowering of the bin.

4. Use the 30mm spanners to loosen the cab

bolts. Raise the cab and ensure the cab tilt lock

is engaged.

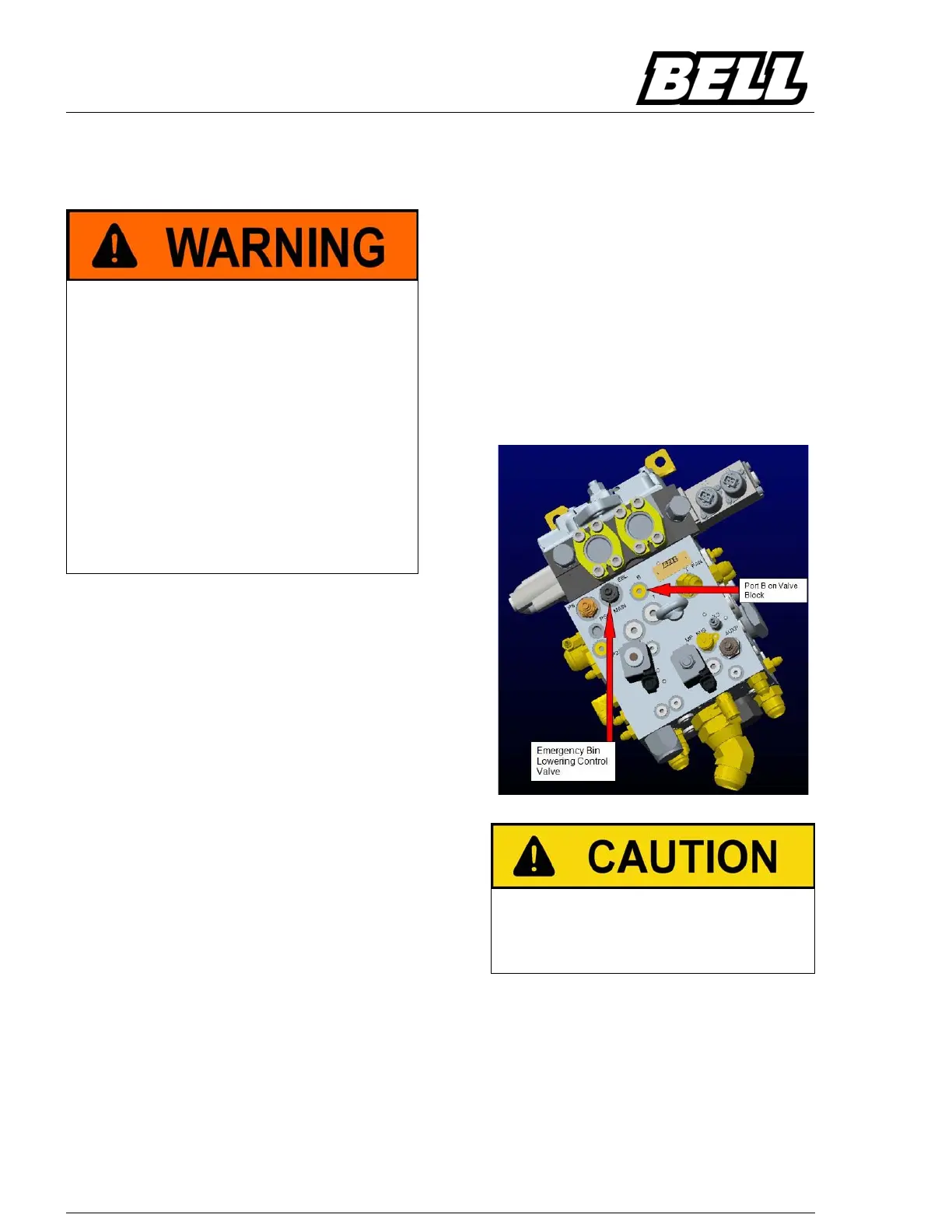

5. Remove the plug on port B from the tip valve

block (1/4” Allen Key). Connect the hose of the

hand pump to port B. The hand pump will be

used to jack the bin back over the center point

of the bin pivots. The weight of the bin will then

be used to lower the bin by controlling the

emergency bin lowering control valve situated

on the side of the tip valve block. Ensure to

place the hand pump in a safe area next to the

machine, clear from the rear chassis and bin of

the machine.

6.

Before continuing with step 7 of this procedure, en-

sure the cab is in the lowered position and the front

chassis and rear chassis are in a straight position,

so when the bin is lowered the bin does not connect

with the cab.

7. Use the 18mm spanner to loosen the lock nut

of the emergency bin lowering control valve.

This valve is situated on the top face of the tip

valve block.

8. Use the 5mm Allen key and slowly turn the

emergency bin lowering control valve counter

clockwisetoopenthevalveforthebintocome

down. The more turns counter clock wise the

faster the bin will lower. If a hand pump is con-

nected to assist with the bin lowering, open the

Loading...

Loading...