9

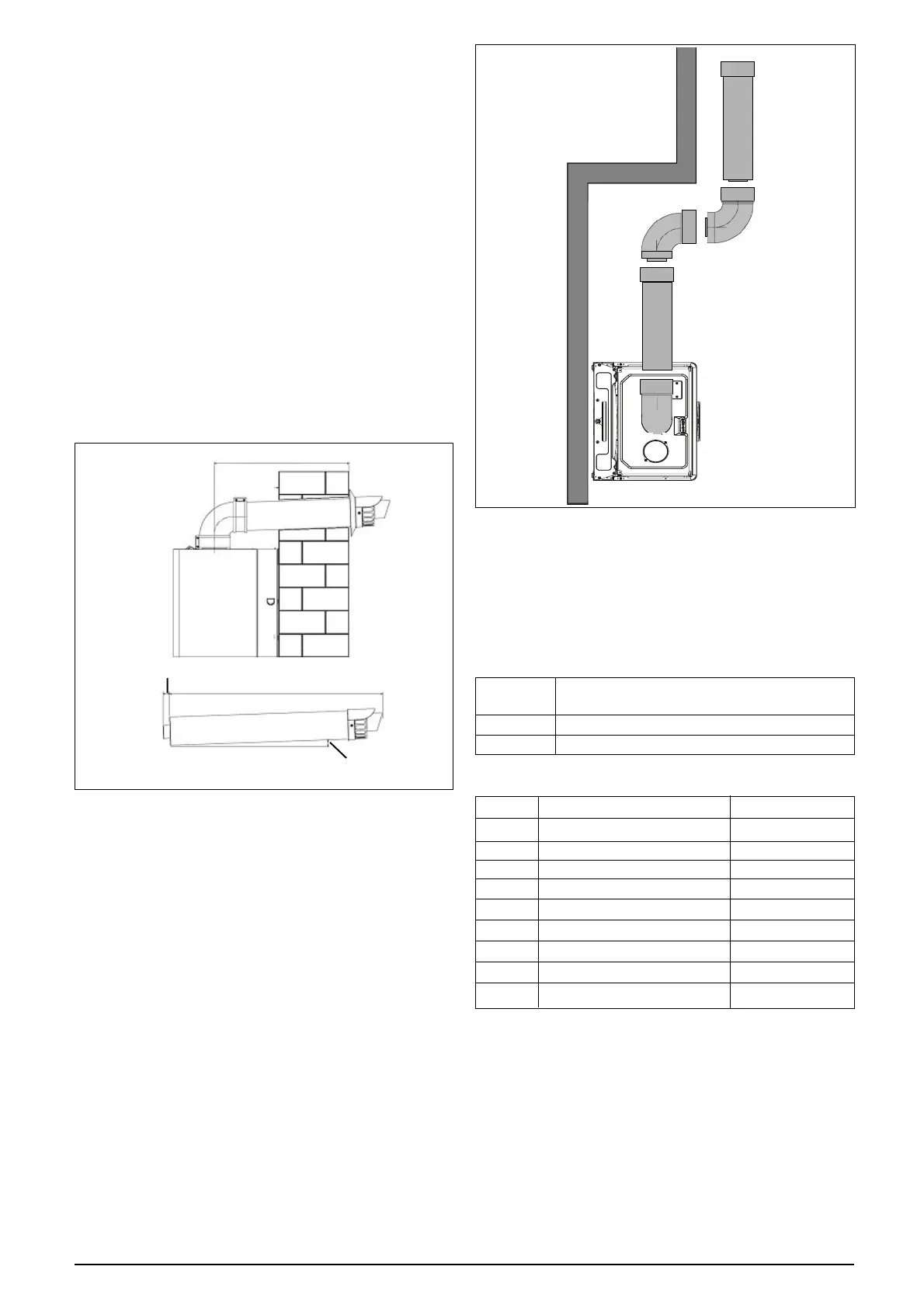

Fig. 9A

FITTING THE HORIZONTAL FLUE KIT

Carefully measure the distance from the centre of

the appliance flue outlet to the edge of the finished

outside wall (dimension X). Add 65mm to dimen-

sion X to give you Dimension Y (see fig 9A).

Measure dimension Y from the terminal end of the

concentric flue pipe and cut off the excess ensur-

ing any burrs are removed. Pass the concentric

flue pipe through the previously drilled hole. Fit the

flue bend to the boiler flue outlet and insert the

concentric flue pipe into the flue bend ensuring the

correct seal is made. Using the clamp, gasket,

and screws supplied, secure the flue bend to the

appliance flue spigot.

NOTE

Fit the internal (white) trim to the flue assembly

prior to connecting the flue pipe to the bend.

You must ensure that the entire flue system is

properly supported and connected. Seal the flue

assembly to the wall using cement or a suitable

alternative that will provide satisfactory weather-

proofing. The exterior trim can now be fitted.

4.5.1.1 EXTENDING THE FLUE

Connect the bend – supplied with the terminal kit

– to the top of the boiler using clamp (supplied)

see fig. 9. The additional bends & extensions have

push-fit connections, care should be taken to en-

sure that the correct seal is made when assem-

bling the flue system. Connect the required number

of flue extensions or bends (up to the maximum

equivalent flue length) to the flue terminal (see

fig. 9 & 10). The flue system should have a mini-

mum of 1º; maximum of 3º rise from the boiler to

outside, to ensure any condense fluid that forms,

is allowed to drain back to the appliance.

NOTE

When cutting an extension to the required length,

you must ensure that the excess is cut from the

plain end of the extension (see fig. 9 & 10). Re-

move any burrs, and check that all seals are lo-

cated properly. You must ensure that the entire

flue system is properly supported and connected.

Seal the flue assembly to the wall using cement

or a suitable alternative that will provide satisfac-

tory weatherproofing. The interior and exterior trim

can now be fitted.

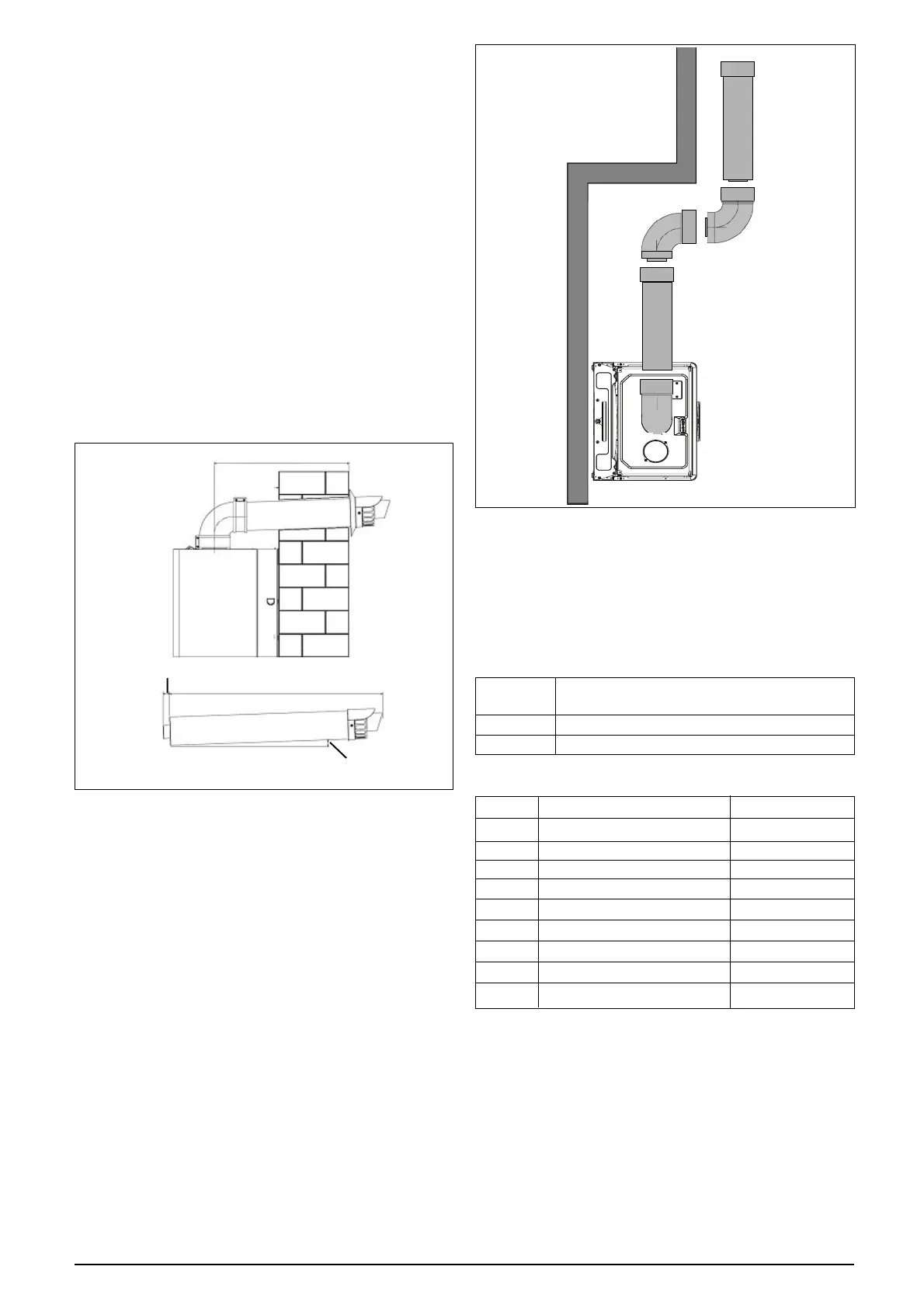

4.5.2 CONCENTRIC VERTICAL FLUE

The vertical flue terminal can be connected directly

to the appliance flue outlet. Alternatively, an exten-

sion or bend can be connected to the appliance flue

outlet if desired (see 4.4.2), however if additional

bends are fitted, a reduction must be made to the

maximum flue length (see table below).

Reduction for bends

Bend Reduction in maximum flue length for each

bend

45º bend 0.5 metre

90º bend 1.0 metre

Vertical flue terminal and accessories

Part No. Description Min-Max Length

490 Vertical flue terminal

497 Pitched roof flashing plate N/A

498 Flat roof flashing plate N/A

492 0.5m extension 500 mm

493 1.0m extension 1000 mm

494 2.0m extension 2000 mm

495 45º bend (pair) N/A

496 90º bend N/A

499 Wall bracket N/A

Using the dimensions given in fig. 9 as a reference, mark

and cut a 115mm hole in the ceiling and/or roof.

“X”

“Y”

30mm

1-3 degree

“X” + 65mm = “Y”

Fig. 10

Loading...

Loading...