30

SECTION 10 LPG INSTRUCTIONS

10.1 RELATED DOCUMENTS

BS 5440 PARTS 1 & 2 FLUES & VENTILATION REQUIREMENTS

BS 5449 PART 1 FORCED CIRCULATION OF HOT WATER SYSTEMS

BS 5482 PART 1 DOMESTIC BUTANE & PROPANE GAS BURNERS IN PERMAMENT

DWELLINGS

BS 5546 INSTALLATION OF GAS HOT WATER SUPPLIES FOR DOMESTIC

PURPOSES

BS 6798 INSTALLATION OF BOILERS OF RATED NOT EXCEEDING 60kW

10.2

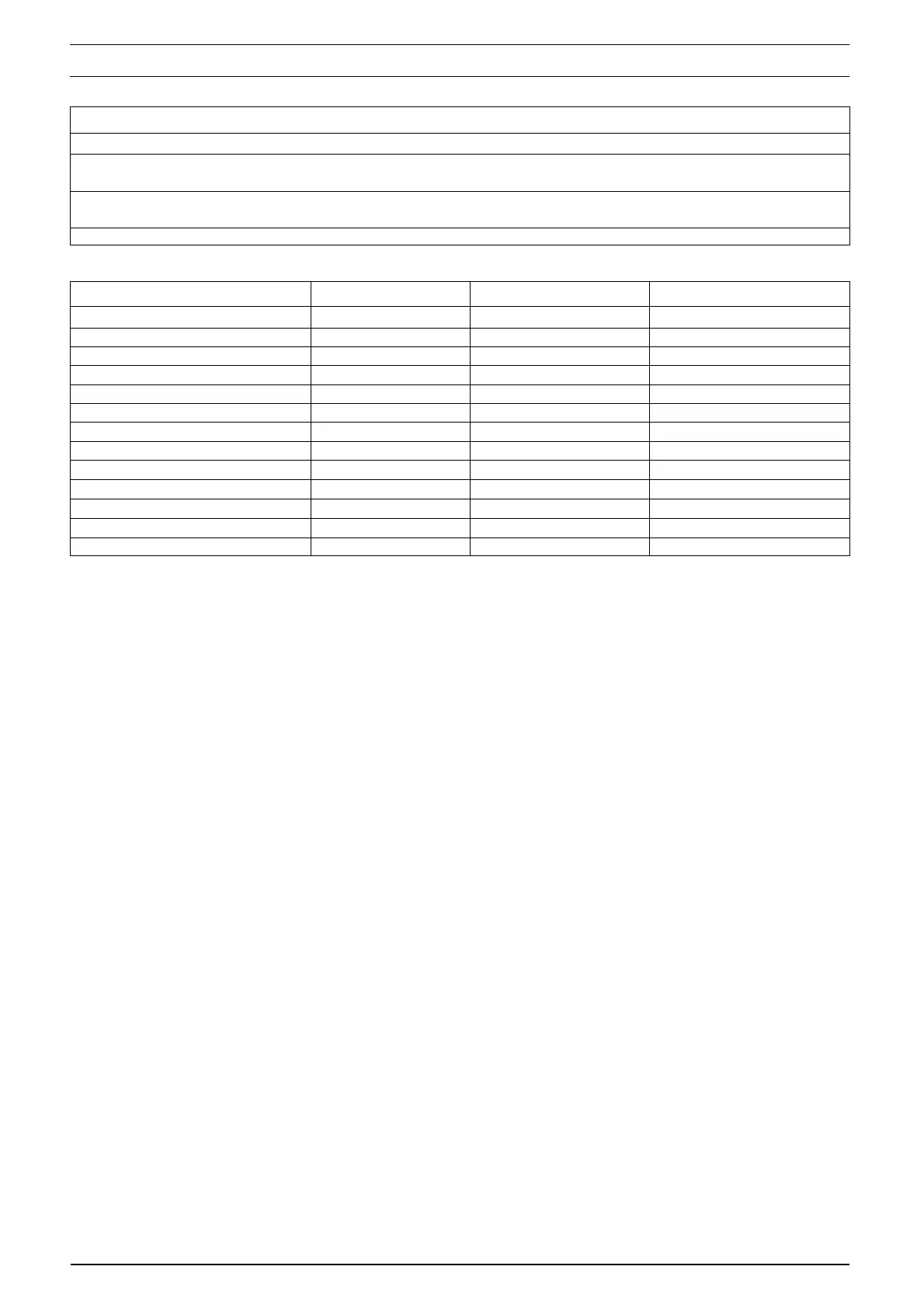

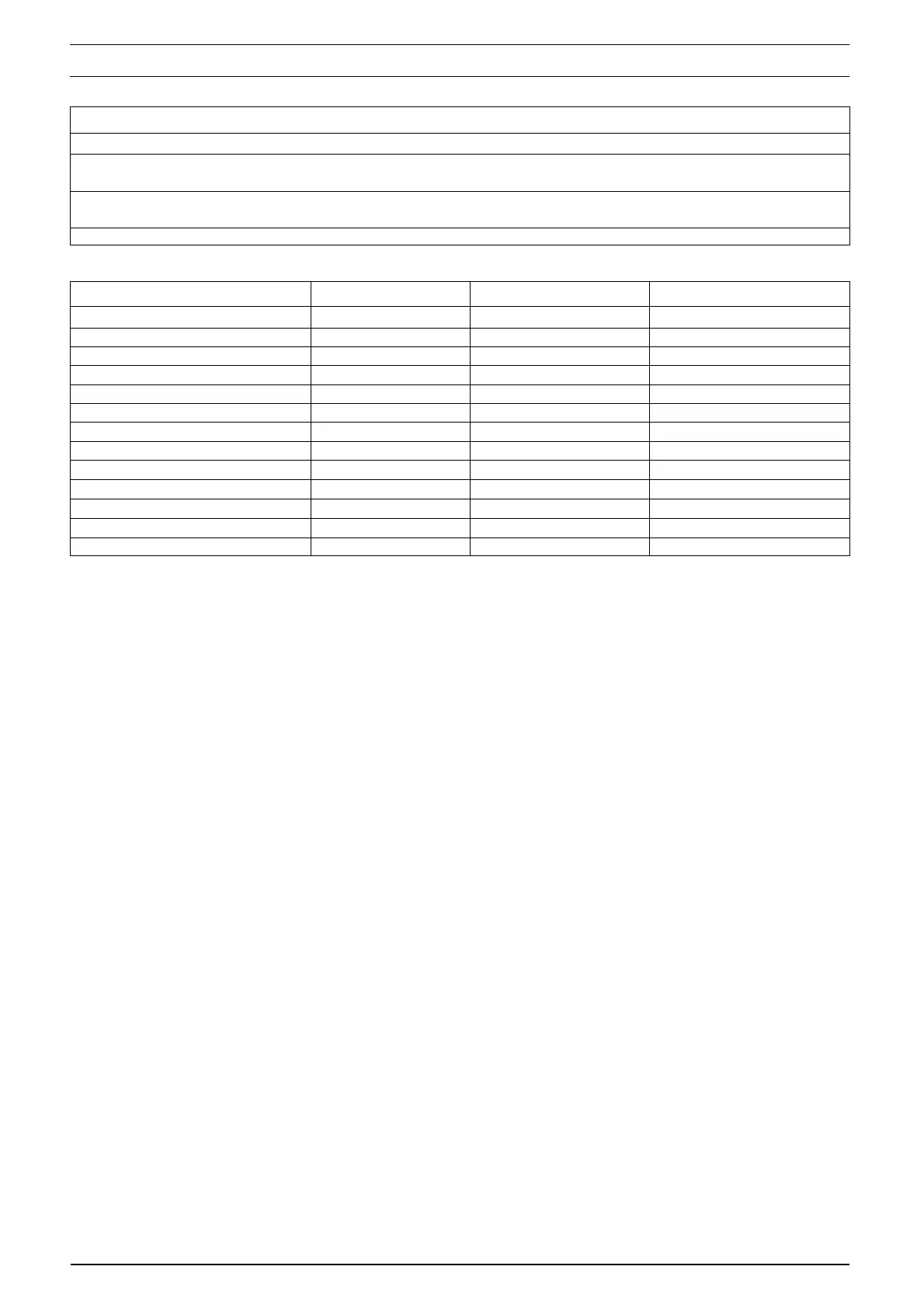

Gas Pressures Procombi A28 Procombi A32 Procombi A36

Inlet pressure 37.0mbar

Maximum gas rate (kg/hr) 2.17 2.48 2.80

Minimum gas rate (kg/hr) 0.47 0.54 0.54

Injector size 4.7mm 4.7mm 5.0mm

CO

2

max (%) 10.0 10.0 10.0

CO

2

min (%) 10.0 10.0 10.0

CO max (mg/kWh) 182.8 215.0 236.5

CO max (mg/kWh) 32.3 21.5 21.5

NOx max (PPM) mg/kWh 70.6 88.3 8.3

NOx min (PPM) mg/kWh 53.0 53.0 70.6

CO/CO

2

ratio @ max 0.002 to 1 0.002 to 1 0.002 to 1

CO/CO

2

ratio @ min 0.004 to 1 0.004 to 1 0.004 to 1

SEDBUK ‘A’ (%) 92.4 2.7 92.7

10.3 CONVERTING THE APPLIANCE GAS TYPE

To convert the appliance to another gas type it is

necessary to change the burner injector, adjust

the appliance fan speeds and adjust the gas valve

(CO

2

).

• To change the injector see 6.12.1

• To adjust the fan speeds see 10.7

• To adjust CO2 values see 10.6

10.4 GAS SUPPLY

The gas supply must be connected to the appli-

ance by a competent LPG installer and must be

of sufficient size to supply the appliance at its

maximum output. An existing supply must be

checked to ensure that it is of adequate size to

deal with the maximum rated input of this and

any other appliances that it serves.

10.5 GAS SUPPLY INSTALLATION

The entire installation including the meter must

be purged and checked for gas soundness.

10.6 CHECKING THE CO

2

AND ADJUSTING THE

GAS VALVE

THE GAS VALVE MUST BE SET-UP OR AD-

JUSTED WITH THE AID OF A PROPERLY CALI-

BRATED FLUE GAS ANALYSER.

Isolate the appliance from the electrical supply

and remove the appliance casing as described in

4.7.1. Set the flue gas analyser to read CO

2

and

insert the probe into the flue analysis test point (A,

B fig. 35). Restore the electrical supply to the

boiler and switch the boiler to the OFF mode. To

adjust the gas valve you must first ensure that the

fan speed potentiometers (trimmers) have been

set correctly (see 10.7).

Remove the 3-selector knobs, locate and press

the CO button (fig. 36). The appliance will now

operate in CO mode for approximately 15-minutes

(see 7.10).

10.6.1 GAS VALVE MAXIMUM SETTING

Locate and gently turn the HTG trimmer till the

maximum value fan speed (max) is obtained and

check that it corresponds with the appropriate CO

2

value (maximum) for the respective appliance. If

the CO

2

reading is correct, proceed to gas valve

minimum setting (10.6.2).

However, if the CO

2

reading is incorrect, the

maximum gas pressure must be adjusted as

follows:

• using a 2.5mm Allen key, very slowly turn the

maximum adjustment screw (fig. 38) – clock-

wise to decrease, counter clockwise to increase

– until the correct value is displayed on the CO

2

analyser (allow time for the analyser to stabi-

lise).

10.6.2 GAS VALVE MINIMUM SETTING

Locate and gently turn the HTG trimmer till the

minimum value fan speed (min) is obtained and

check that it corresponds with the appropriate CO

2

value (minimum) for the respective appliance. If

the CO

2

reading is correct, rotate the HTG trim-

mer until the correct value is obtained for the re-

spective appliance (see fan speed table) and pro-

ceed to 10.6.3.

However, if the CO

2

reading is incorrect, the mini-

mum gas pressure must be adjusted as follows:

• using a suitable screwdriver, very slowly turn the

minimum adjustment screw (fig. 38) – clockwise

to increase, counter clockwise to decrease -

until the correct value is displayed on the CO

2

analyser (allow time for the analyser to stabi-

lise).

Loading...

Loading...