7

3.6.5 EXPANSION VESSEL

The appliance has an integral expansion vessel to

accommodate the increased volume of water

when the system is heated. It can accept up to 8

(28HE) or 10 (32 & 36HE) litres of expansion from

within the system, generally this is sufficient,

however if the system has an unusually high water

content, it may be necessary to provide additional

expansion capacity (see 6.19).

3.6.6 FILLING POINT

An approved method for initial filling of the system

and replacing water lost during servicing etc.

directly from the mains supply, is required (see

fig. 5). This method of filling complies with the

current Water Supply (Water Fittings) Regulations

1999 and Water Bylaws 2000 (Scotland).

3.6.7 LOW PRESSURE SEALED SYSTEM

An alternative method of filling the system would

be from an independent make-up vessel or tank

mounted in a position at least 1 metre above the

highest point in the system and at least 5 metres

above the boiler (see fig. 6).

The cold feed from the make-up vessel or tank

must be fitted with an approved non-return valve

and stopcock for isolation purposes. The feed pipe

should be connected to the return pipe as close

to the boiler as possible.

3.6.8 FREQUENT FILLING

Frequent filling or venting of the system may be

indicative of a leak. Care should be taken during

the installation of the appliance to ensure all

aspects of the system are capable of withstanding

pressures up to at least 3 bar.

3.7 ELECTRICAL SUPPLY

The appliance is supplied for operation on 230V @

50Hz electrical supply; it must be protected with a

3-amp fuse. The method of connection to the

mains electricity supply must allow for complete

isolation from the supply. The preferred method is

by using a double-pole switch with a contact

separation of at least 3,5mm (3° high-voltage

category). The switch must only supply the appli-

ance and its corresponding controls, i.e. time

clock, room thermostat, etc. Alternatively an un-

switched shuttered socket with a fused 3-pin plug

both complying with BS 1363 is acceptable.

3.8 MOUNTING ON A COMBUSTIBLE SURFACE

If the appliance is to be fitted on a wall of combus-

tible material, a sheet of fireproof material must

protect the wall.

3.9 TIMBER FRAMED BUILDINGS

If the appliance is to be fitted in a timber framed

building, it should be fitted in accordance with the

Institute of Gas Engineers publication (IGE/UP/7)

‘Guide for Gas Installations in Timber Frame

Buildings’.

3.10 INHIBITORS

It is recommend that an inhibitor - suitable for use

with copper and aluminium heat exchangers - is

used to protect the boiler and system from the

effects of corrosion and/or electrolytic action. The

inhibitor must be administered in strict accord-

ance with the manufacturers instructions*.

*Water treatment of the complete heating system

- including the boiler - should be carried out in

accordance with BS 7593 and the Domestic Water

Treatment Association’s (DWTA) code of prac-

tice.

3.11 SHOWERS

If the appliance is intended for use with a shower,

the shower must be thermostatically controlled

and be suitable for use with a combination boiler.

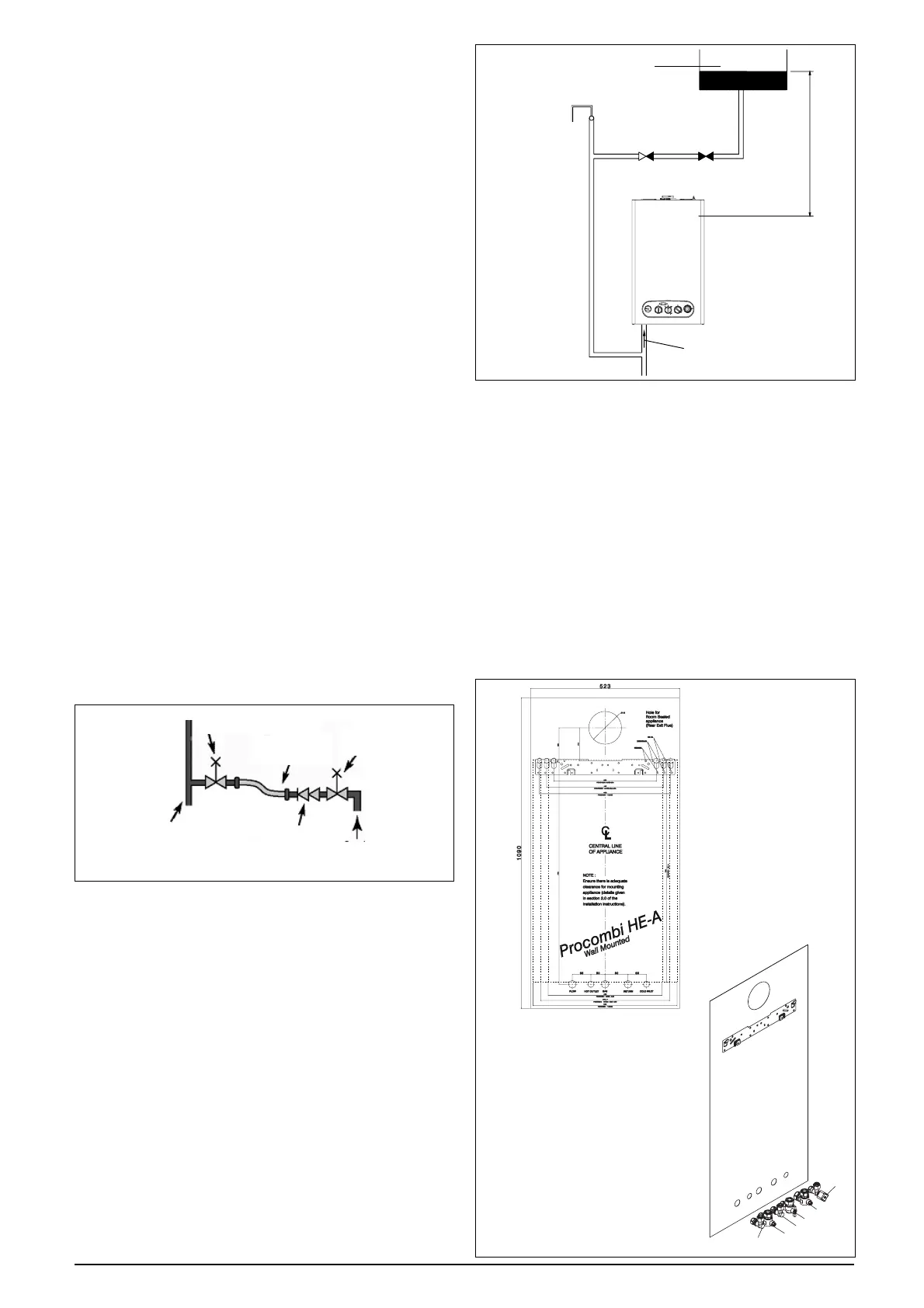

fig.5

Make-up vessel

or tank

Automatic

air-vent

Non-return

valve

Stopcock

5.0 metres minimum

Heating

return

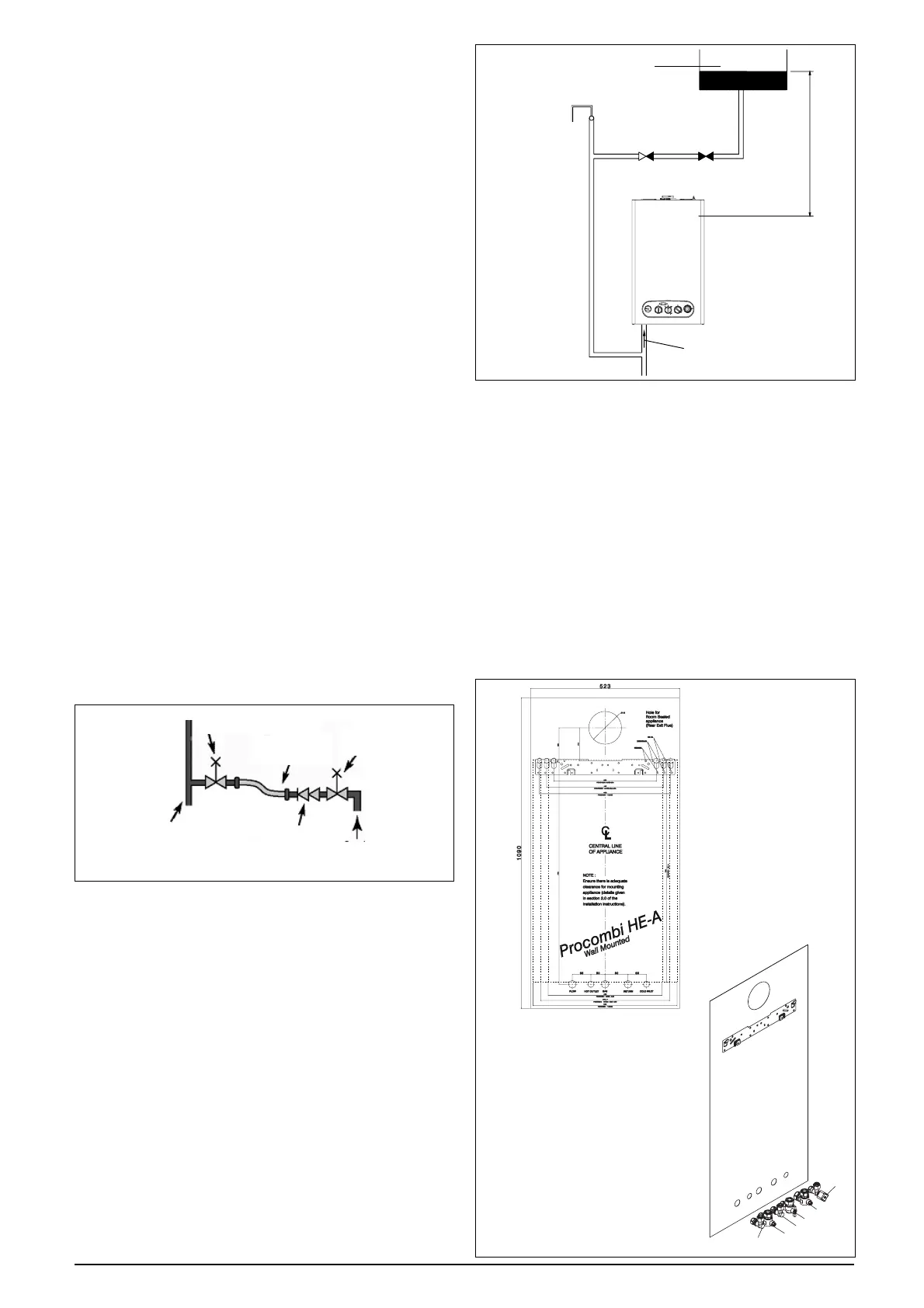

fig.6

flow/return

pipe

control

valve

temporary

connection

control

valve

supply

pipe

double

check valve

fig. 7

fig. 8

A - safety valve outlet

B - flow

C - DHW outlet

D - gas

E - return

F - DHW inlet

A

B

C

D

E

F

Loading...

Loading...