13Bend-Tech Dragon A400

Plasma Cutting Guide

Consumables

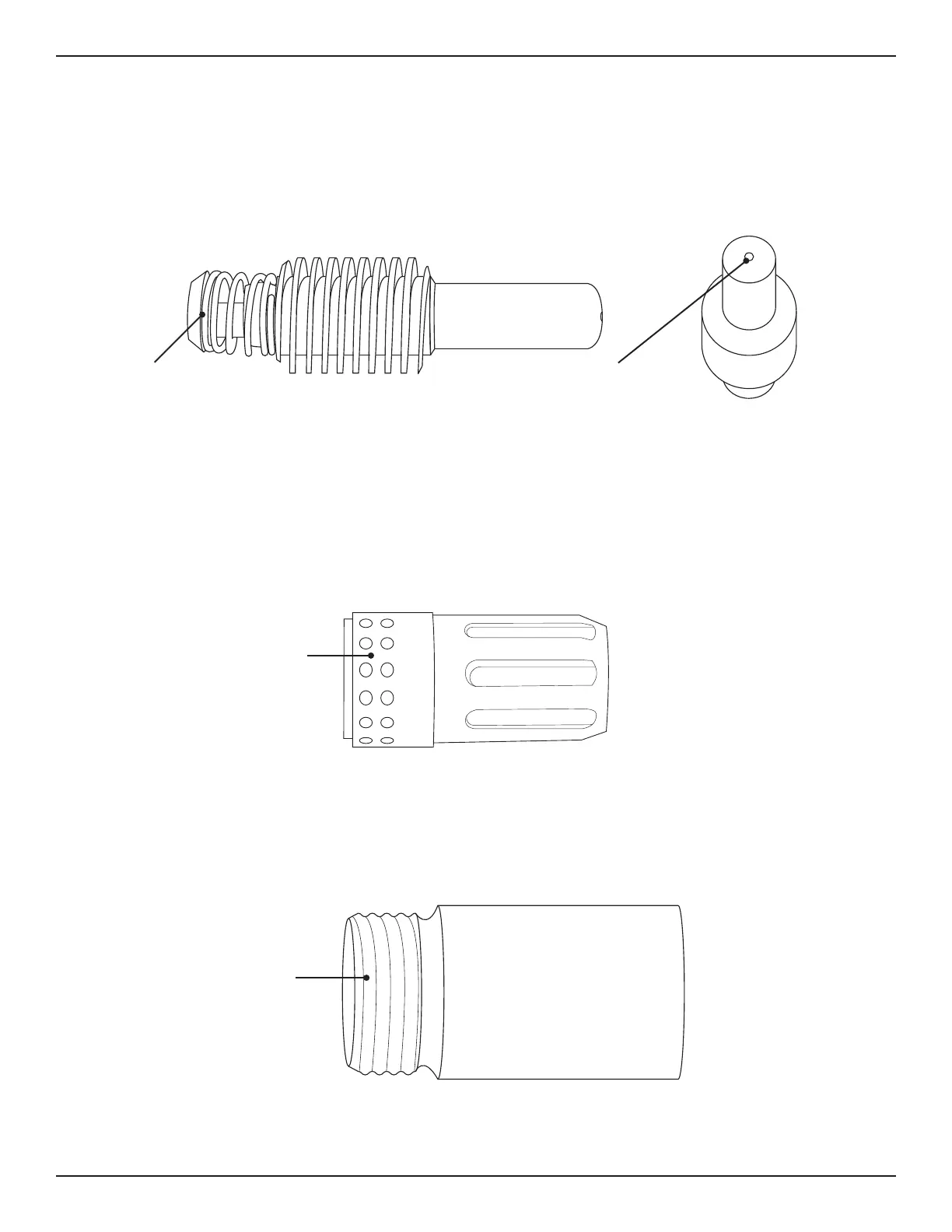

01

deteriorate as the Torch is used. Once pit depth reaches .040-.045 in. the electrode and nozzle

should be replaced. To determine pit depth, measure the distance from the surface of the

electrode to the bottom of the pit of the electrode. Use a quality pit depth gauge. Follow the

manufacturer’s recommendations for pit depth.

In the case of a spring electrode ensure the spring is intact and moves freely.

Swirl Ring

Inspect the swirl ring for cracks, deformations and clogged holes. The swirl ring does not wear

like the electrode and nozzle, but it can become cracked from heat cycling or from some sort

of physical damage. The swirl ring will only need to be replaced if there is evidence of physical

damage.

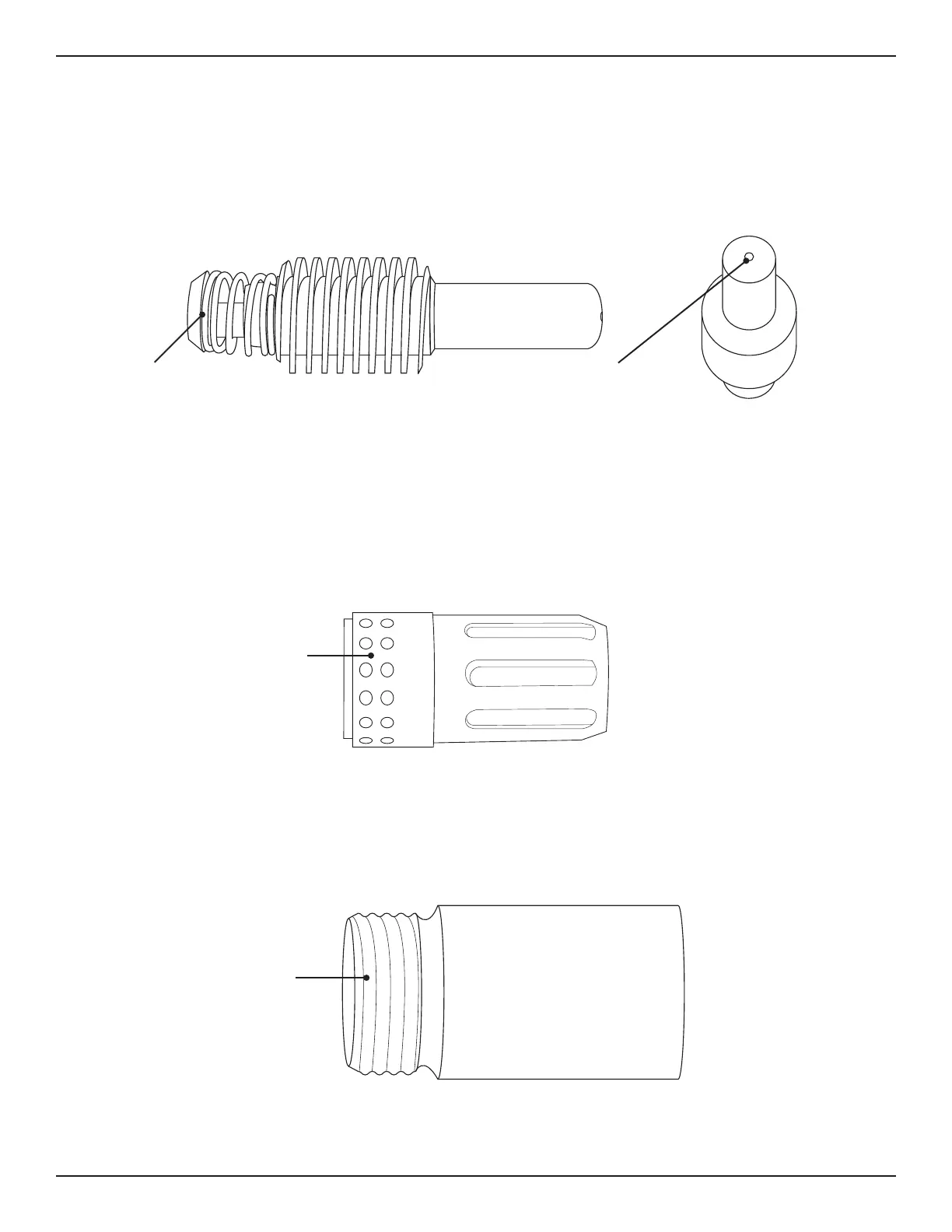

Retaining Cap

Ensure the retaining cap is free of slag and not cracked, and that the threads are intact. Dirt

can damage the retaining cap threads. Heat can damage the retaining cap.

Make sure spring is

intact and moves freely.

Pit depth measured

here.

Make sure the swirl

ring has no cracks or

deformations, and that

the holes are clear.

Make sure the threads

are clean and intact.

Loading...

Loading...