27Bend-Tech Dragon A400

Plasma Cutting Guide

Troubleshooting

03

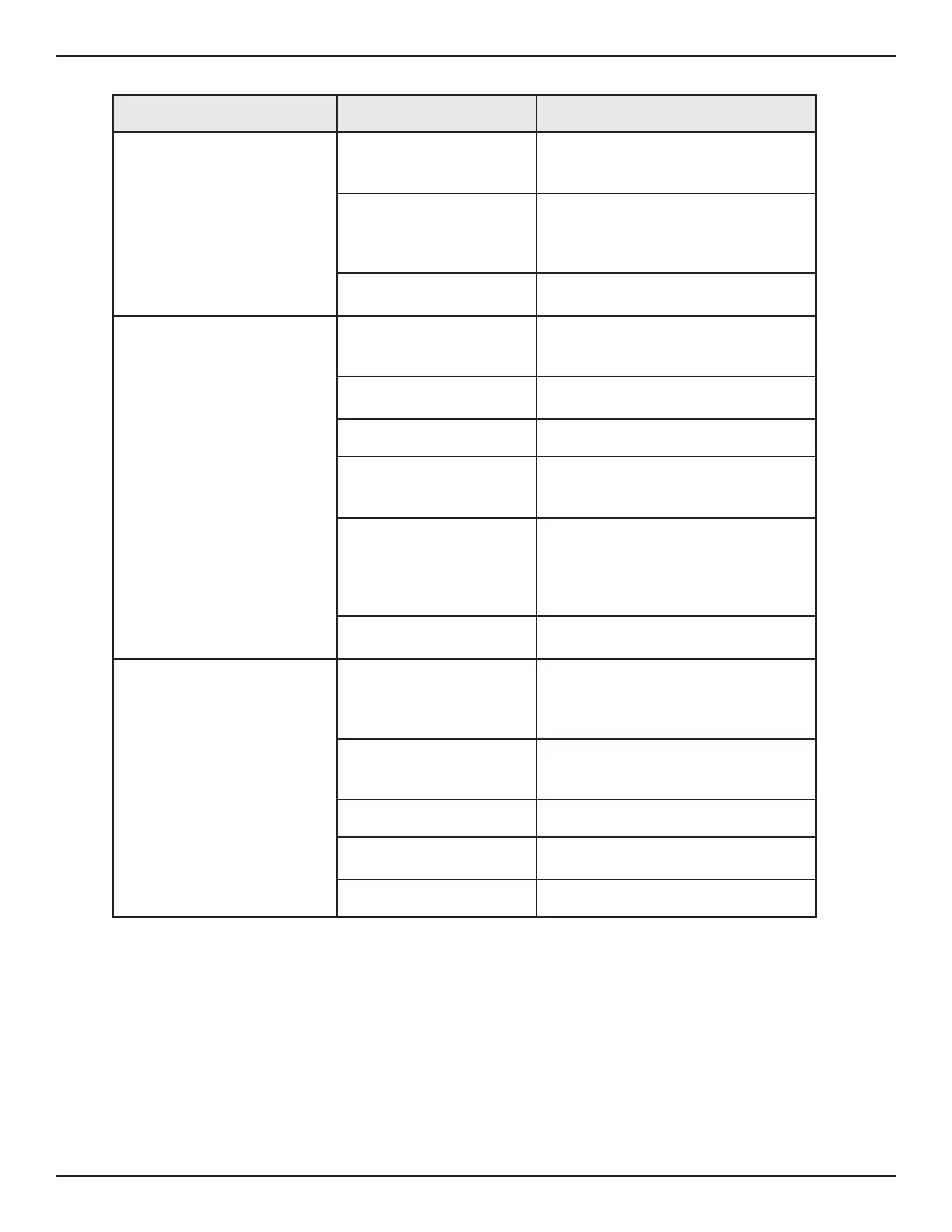

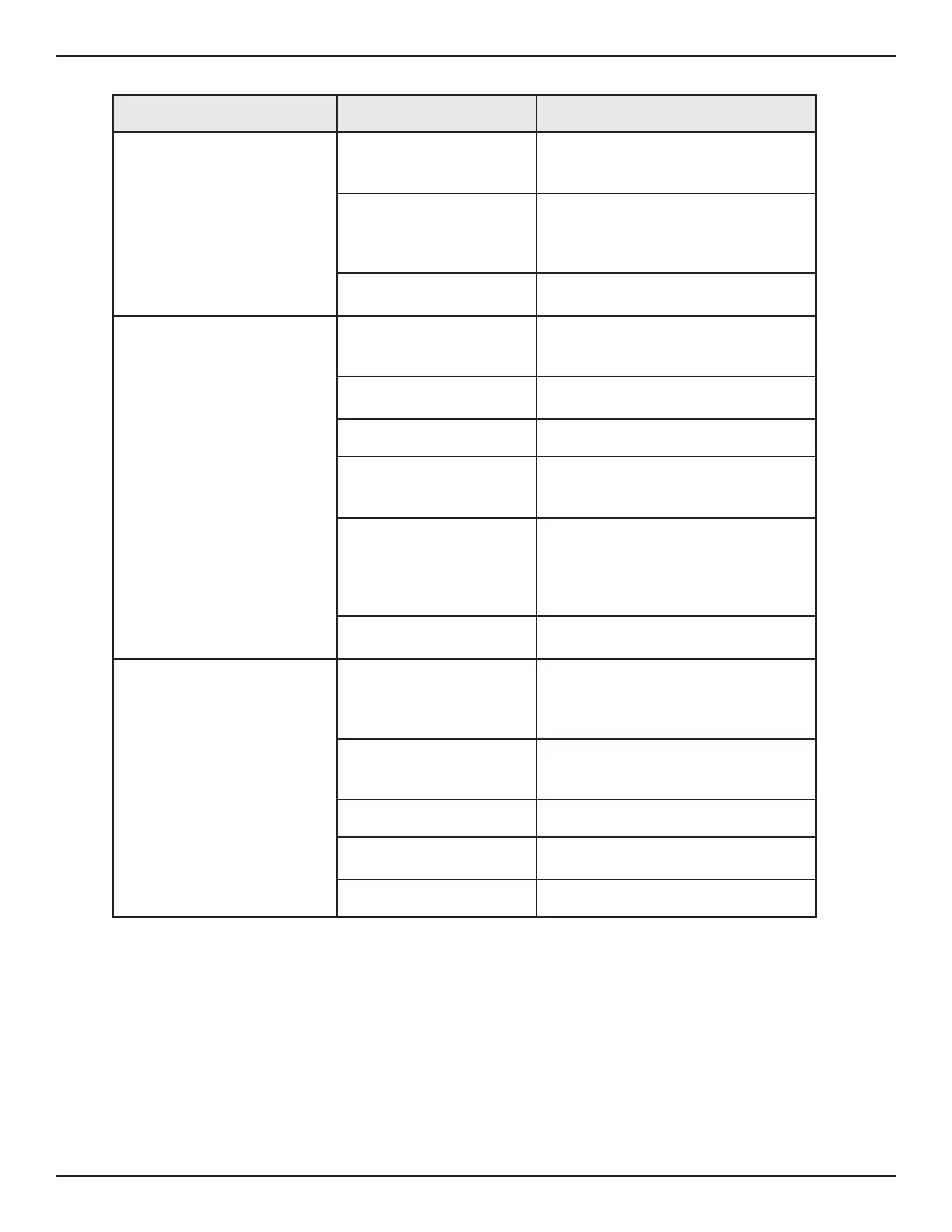

Symptom Cause Corrective Action

Jagged Cuts

Material feed rate too high

Ensure consumables match the

amperage settings on the machine.

Set cut speed appropriately.

Amperage incorrect

Ensure amperage is set to cutting

charts in this manual. It is possible the

amperage may need to be adjusted by

the Operator to achieve best results.

Gate too tight on material

Ensure material moves freely in Gate

with no play.

Torch Not Firing

Hypertherm not powered

on

Check Hypertherm power switch;

check power cable; check cable to

Control Box.

Torch set too high

Check Torch height with feeler gauge;

perform Torch Mount procedure.

Improper air supply Check air supply, check air pressure.

Consumables

Remove and inspect Torch

consumables. Refer to Consumables

Guide.

Bad ground

Ensure ground clamp is connected;

ensure ground cable is secured on

Trolley; ensure alligator clamp is

securely connected toground cable on

Dragon A400.

Torch wand not switched

on

Check switch on Torch wand.

Torch Colliding with

Material

Material selected in

software does not match

material loaded into

machine

Check to ensure material chosen in

software matches material loaded in

the machine.

Material dimensions

entered incorrectly in Tube

Library

accurate with those entered in Tube

Library.

Torch set improperly Perform Torch Mount procedure.

performed

the given material.

Gate out of position Perform Gate homing procedure.

Loading...

Loading...