SP-7XE/F Full-Rise Scissor Lift 25 P/N 5900010 — Rev. B3 — September 2023

To anchor and level your Bases:

Both Ramps must be resting on the Top Safety Lock to perform this procedure.

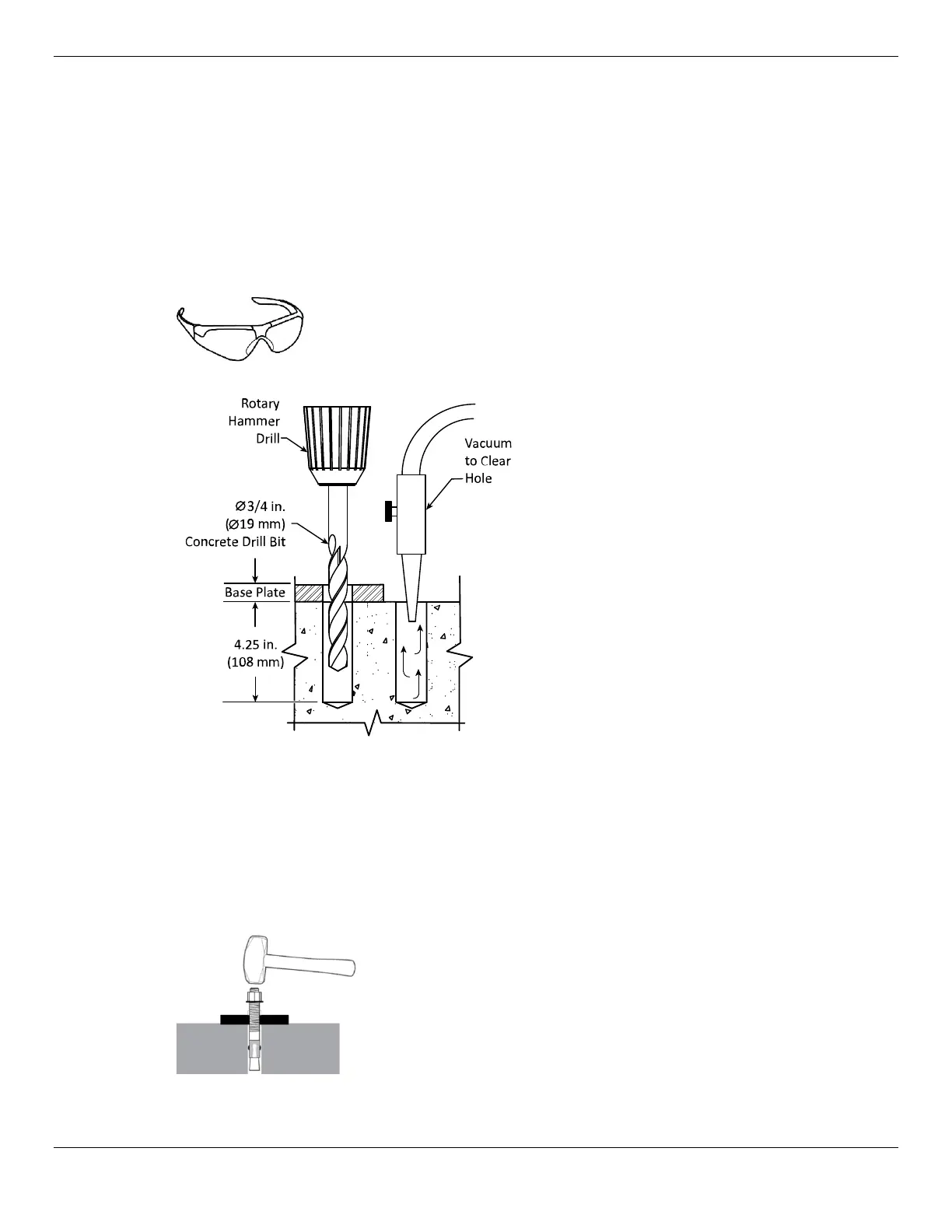

1. Make sure the Bases are in the correct location, then use the holes in the Bases as guides, drill the

holes for the Anchor Bolts.

Four Anchor Bolt openings are located on the Base of the Frame.

Note: If you prefer, you can mark the Anchor Bolt hole locations, move the Frames out of the way,

drill the holes, and then move the Frames back into position.

WARNING Always wear appropriate

eye protection and

protective gear.

Drill in straight and perpendicular; do not let the

drill wobble.

Use a carbide bit for concrete and hammer

drilling applications (conforming to ANSI

B212.15).

The diameter of the drill bit must be the same

as the diameter of the Anchor Bolt. So, if you

are using a ¾ inch diameter Anchor Bolt, for

example, use a ¾ inch diameter drill bit. Check

the diameter of the drill bit before you begin!

Note: BendPak recommends drilling a pilot

hole first. If the final hole size is to be Ø.75 in. /

Ø19 mm, drill a Ø.375 in. to Ø.5 in. (Ø9.5 mm

Ø12.7 mm) pilot hole first.

Pilot holes allow straighter drilling by removing

the material directly in the center of the final drill.

This reduces the amount of force required to

keep the drill straight and perpendicular to the

floor. Verify the drill flutes are at least 4.25 in /

108 mm long to aid in removal of the debris

from the drill hole.

2. Use a vacuum to thoroughly clean each hole. If a Vacuum is not available, use a wire brush, hand

pump, or compressed air.

Do not ream the hole. Do not make the hole any wider than the drill bit made it.

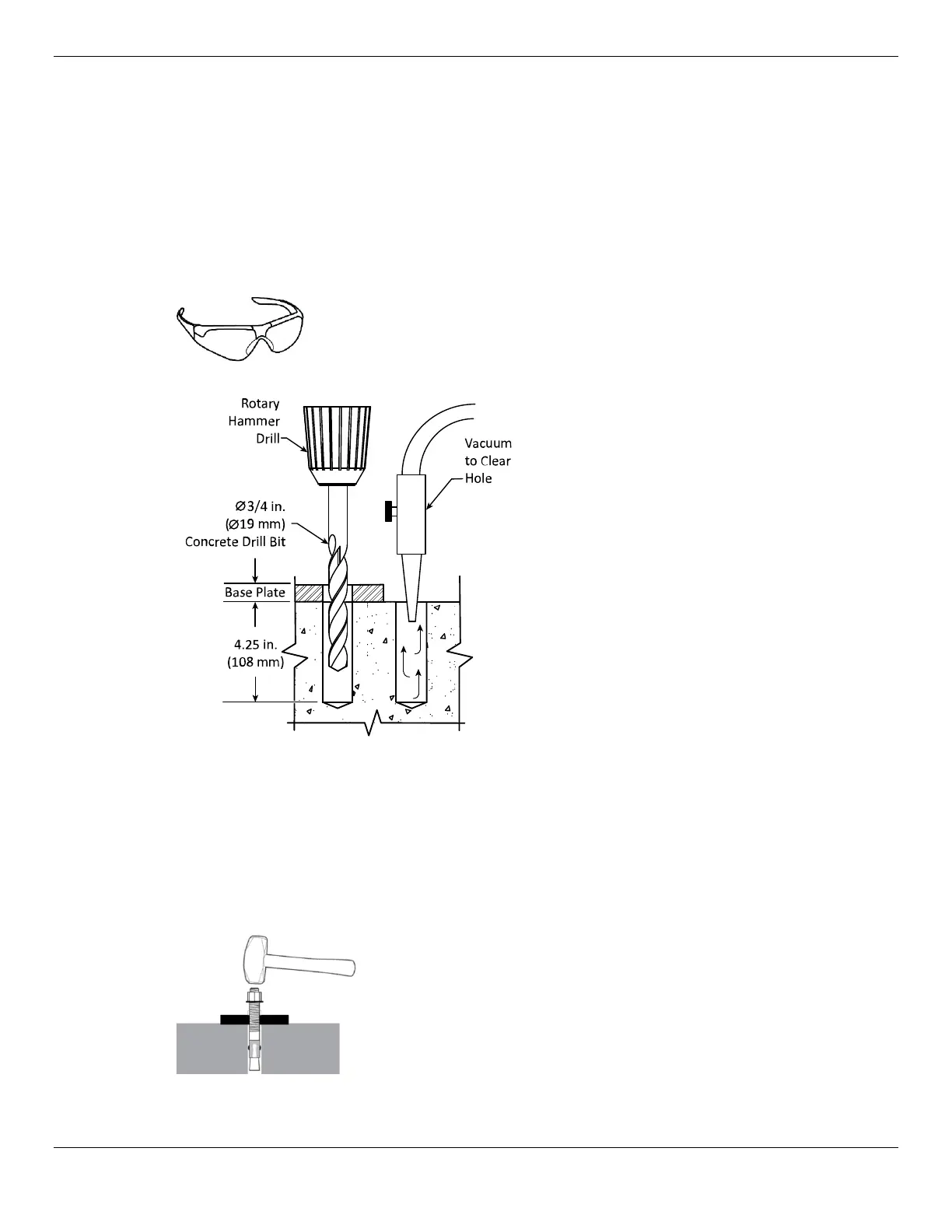

3. Do not immediately hammer the Anchor all the way in. Verify the Washer and Nut are in place,

then insert the Anchor Bolt into the hole. You want approximately 1/4 inch to 1/3 inch (6 to 8 mm)

of thread visible above the Nut. Tap it in until the threads are just entering the Base.

The Expansion Sleeve may prevent the Anchor Bolt from

passing through the hole in the Base; this is normal. Use a

hammer or mallet to lightly tap the Expansion Sleeve through

the Base and down into the hole.

Even using a hammer or mallet, the Anchor Bolt should only go

into the hole part of the way; this is normal. If the Anchor Bolt

drops all the way in with little or no resistance, the hole is too

wide.

Loading...

Loading...