INSTRUCTIONS PUMP TYPE DANFOSS BFP41

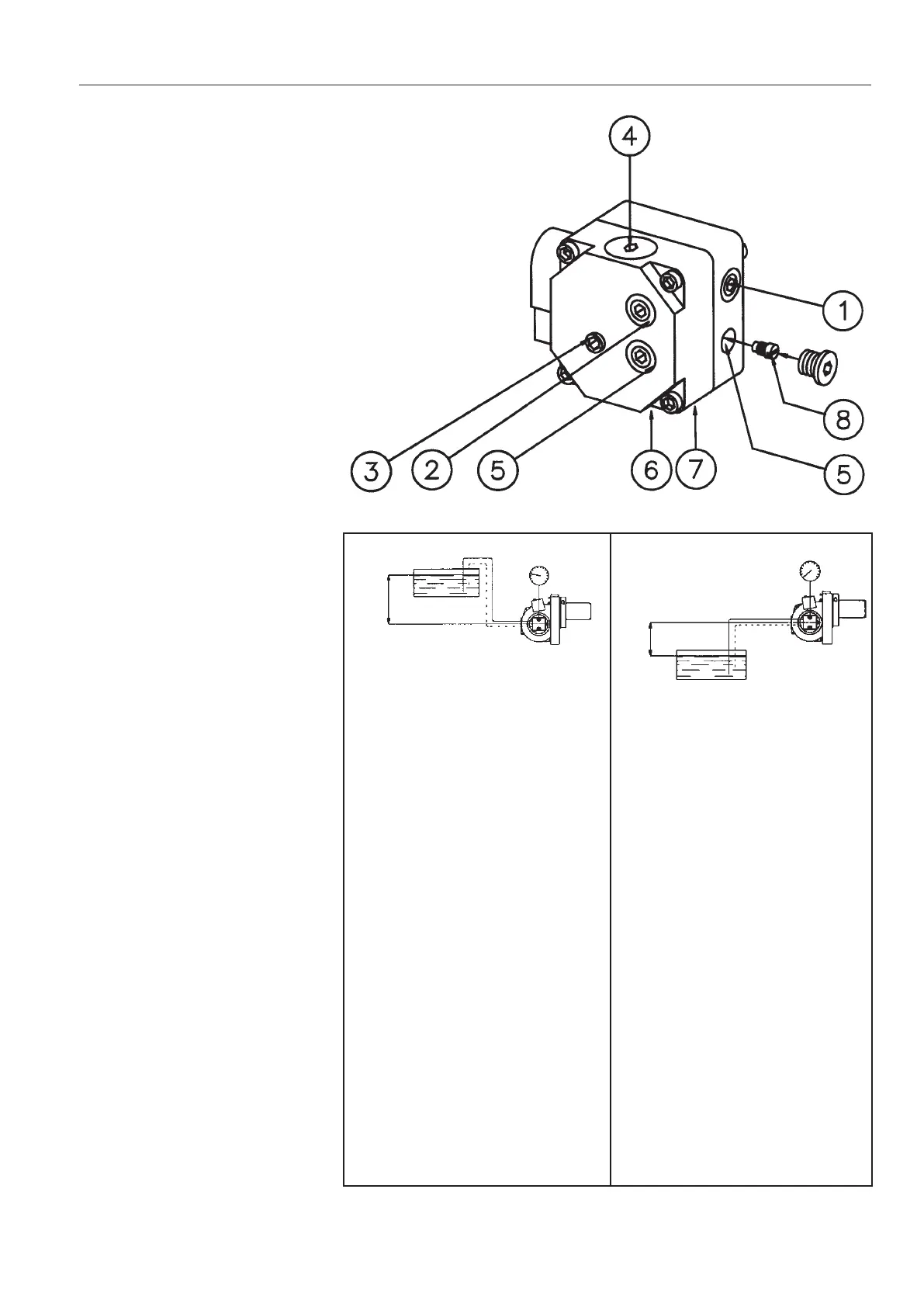

Components

2. Pressure gauge port

3. Pressure adjustment, 4mm allen key

8. Return plug

Technical data

Viscosity range: 1,3-12,0 mm

2

Pressure range: 7-15 bar

Oil temperature: -10 to +70°C

Suction line tables

The suction line tables consist of

theoretically calculated values where

the pipe dimensions and oil velocity

have been matched so that turbulences

will not occur. Such turbulences will

result in increased pressure losses and

in acoustic noise in the pipe system. In

addition to drawn copper piping a pipe

system usually comprises 4 elbows, a

non-return valve, a cut-off valve and an

The sum of these individual resistances

disregarded. The tables do not include

any lengths exceeding 100 m as

experience shows that longer lengths

are not needed.

The tables apply to a standard fuel

oil of normal commercial quality

according to current standards. On

commis sioning with an empty tube

system the oil pump should not be

run without oil for more than 5 min.

(a condition is that the pump is being

The tables state the total suction line

length in metres at a nozzle capacity

pressure at the suction and pressure

side is 2,0 bar.

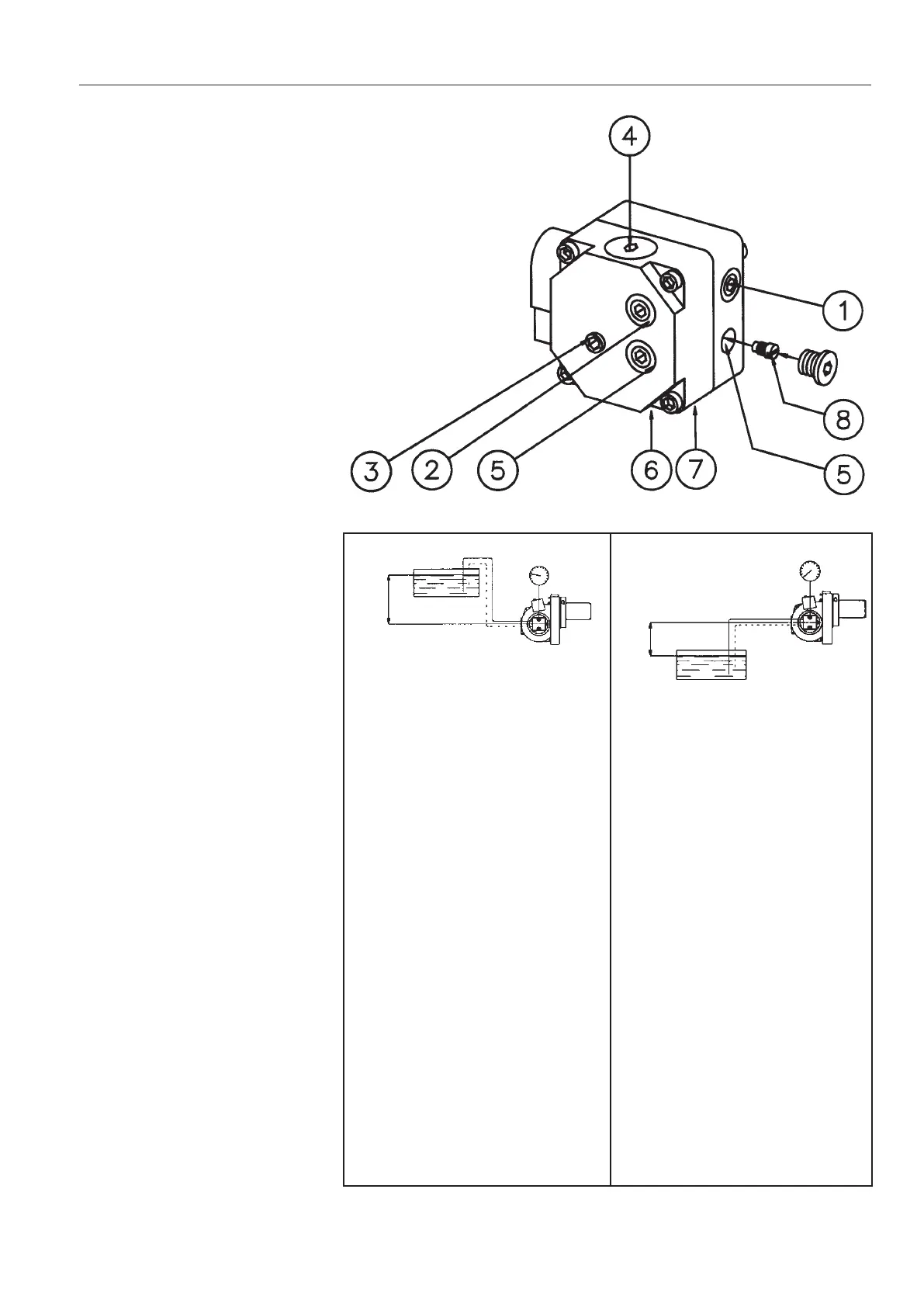

Purging

On 1-pipe systems it is necessary to

purge the pump. On 2-pipe systems

purging is automatic through the

return line.

171 505 07 10-01

Two-pipe system

Height Pipe diameter

H ø6 mm ø8 mm ø10 mm

m m m m

0 17 53 100

-0,5 15 47 100

-1,0 13 41 99

-1,5 11 34 84

-2,0 9 28 68

-2,5 7 22 53

-3,0 5 15 37

-3,5 3 9 22

4,0 1 3 6

Height Pipe diameter

H ø4 mm ø5 mm ø6 mm

m m m m

Height Pipe diameter

H ø6 mm ø8 mm ø10 mm

m m m m

4,0 33 100 100

3,5 31 98 100

3,0 29 91 100

2,5 27 85 100

2,0 25 79 100

1,5 23 72 100

1,0 21 66 100

0,5 19 60 100

Height Pipe diameter

H ø4 mm ø5 mm ø6 mm

m m m m

4,0 51 100 100

3,5 45 100 100

3,0 38 94 100

2,5 32 78 100

2,0 26 62 100

1,5 19 47 97

1,0 13 31 65

0,5 6 16 32

1-pipe system 1-pipe system

system is not recommended

Two-pipe system

H

H

Loading...

Loading...