Do you have a question about the Bentone B 40 and is the answer not in the manual?

Checks if the burner was delivered undamaged and all parts are present.

Outlines safety precautions before and during burner installation.

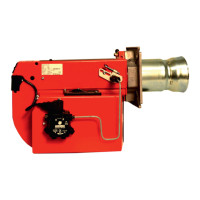

Provides physical dimensions and specifications for the B 40 burner.

Details hole patterns and installation considerations for the burner flange.

Shows the operating range in mbar vs kW for the burner.

Illustrates how to set the nozzle assembly and air damper for optimal performance.

Lists key electrical and performance parameters of the burner.

Explains the correct positioning for ignition electrodes and brake plate.

Discusses nozzle types and recommended pump pressure settings.

Identifies and labels the various parts of the burner with numbered diagrams.

Describes the function and requirements of the burner's safety system components.

Provides a detailed schematic for the burner's electrical connections and components.

Explains the operational sequence and logic of the LMO14/24 control unit.

Details the meaning of signal light colours for normal and abnormal burner operation.

Lists fault codes indicated by flash patterns and their respective causes.

General guidelines for installing oil burners according to local regulations.

Specifies maintenance intervals and environmental considerations for the system.

Procedures for initial burner start-up, including flue gas analysis.

Checks required to ensure burner suitability for the specific boiler.

Guidelines for designing and installing the oil supply system for reliability.

Procedures for safely connecting the burner's electrical system.

Provides guidance on safe methods for handling and lifting the burner unit.

Instructions for checking the tightness of oil line connections after installation.

Provides sample settings for initial burner start-up and flame establishment.

Details how to adjust the air damper for optimal combustion based on flue gas analysis.

Explains how to adjust the brake plate position for favourable pressure drop.

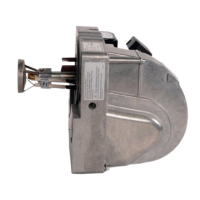

Technical data and component identification for SUNTEC AS pumps.

Describes how the SUNTEC AS pump operates, including solenoid valve function.

Explains the rapid cut-off mechanism of the solenoid valve in the SUNTEC AS pump.

Procedures for bleeding air from the pump system for both one and two-pipe setups.

Suction line tables for systems with an overlying tank, detailing pipe dimensions.

Suction line tables for systems with an underlying tank, detailing pipe dimensions.

Routine check for oil leaks in coupling elements after installation.

Step-by-step guide for replacing the oil pump filter.

Instructions for replacing the solenoid valve on the pump.

Guide for replacing the gasket seal on the oil pump.

Recommended service intervals and tasks for the oil burner.

Lists recommended replacement intervals for various burner components.

Steps for servicing the combustion components, including nozzle and electrodes.

Procedure for cleaning and maintaining the air damper mechanism.

Instructions for servicing the fan motor and fan wheel.

Step-by-step guide for replacing the oil pump assembly.

General procedure for replacing electrical components in the burner.

Troubleshooting guide for symptoms when the burner fails to start.

Troubleshooting common faults that cause the burner to stop or fail to restart.

Identifies causes and remedies for delayed ignition or pulsating start.

Addresses issues related to noise emitted by the oil pump during operation.

Troubleshooting steps for when the burner pump fails to build adequate pressure.