9

SEWING MACHINE TROUBLESHOOTING GUIDE

In most cases poor sewing results and breakdowns are caused

by three main factors:

1. The condition of the needle.

2. Threading and the quality of thread being used.

3. Mechanical breakdown or damaged parts.

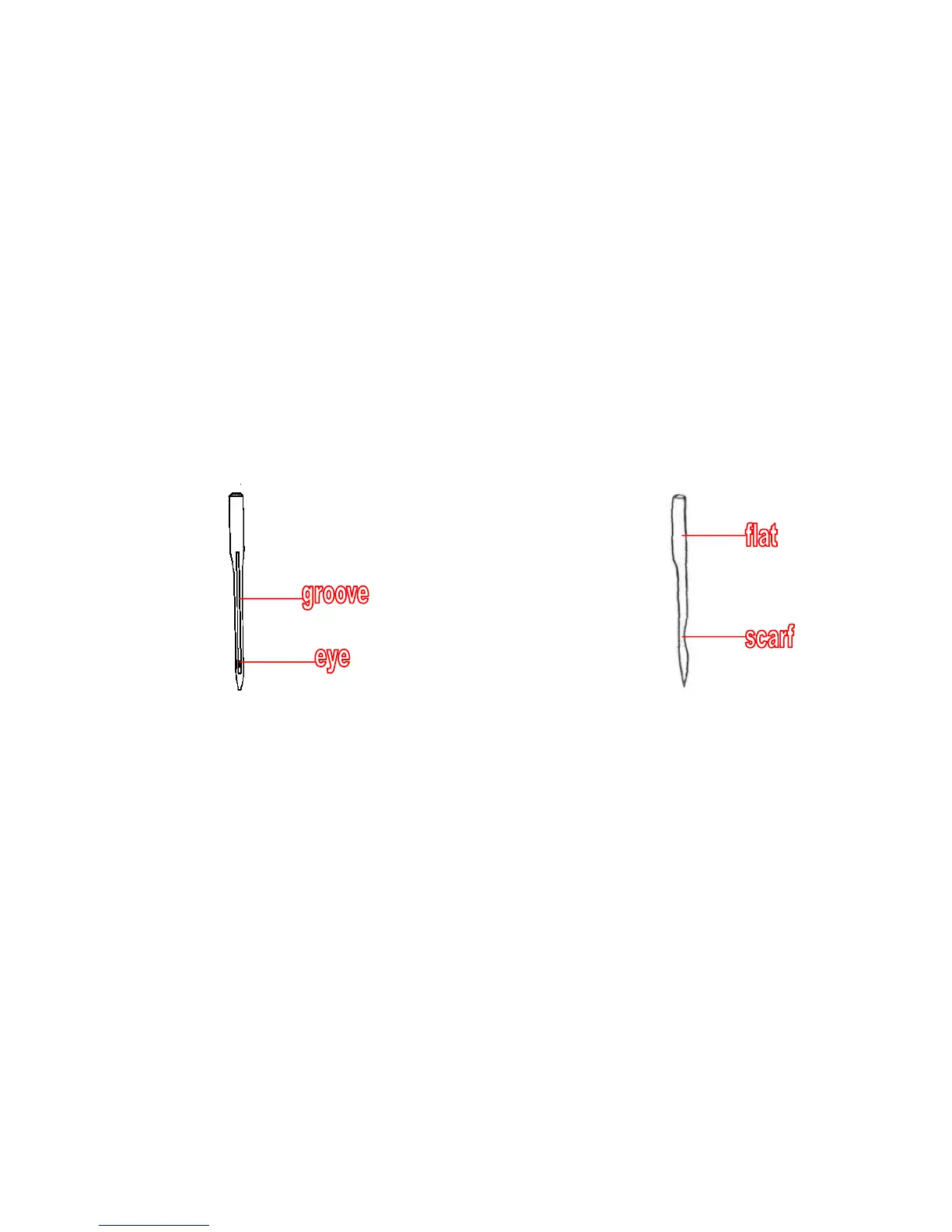

The condition of the needle is the most common problem. Bent or

damaged needles will cause many different sewing problems. The

way the needle is inserted into the needle clamp is also very

important.

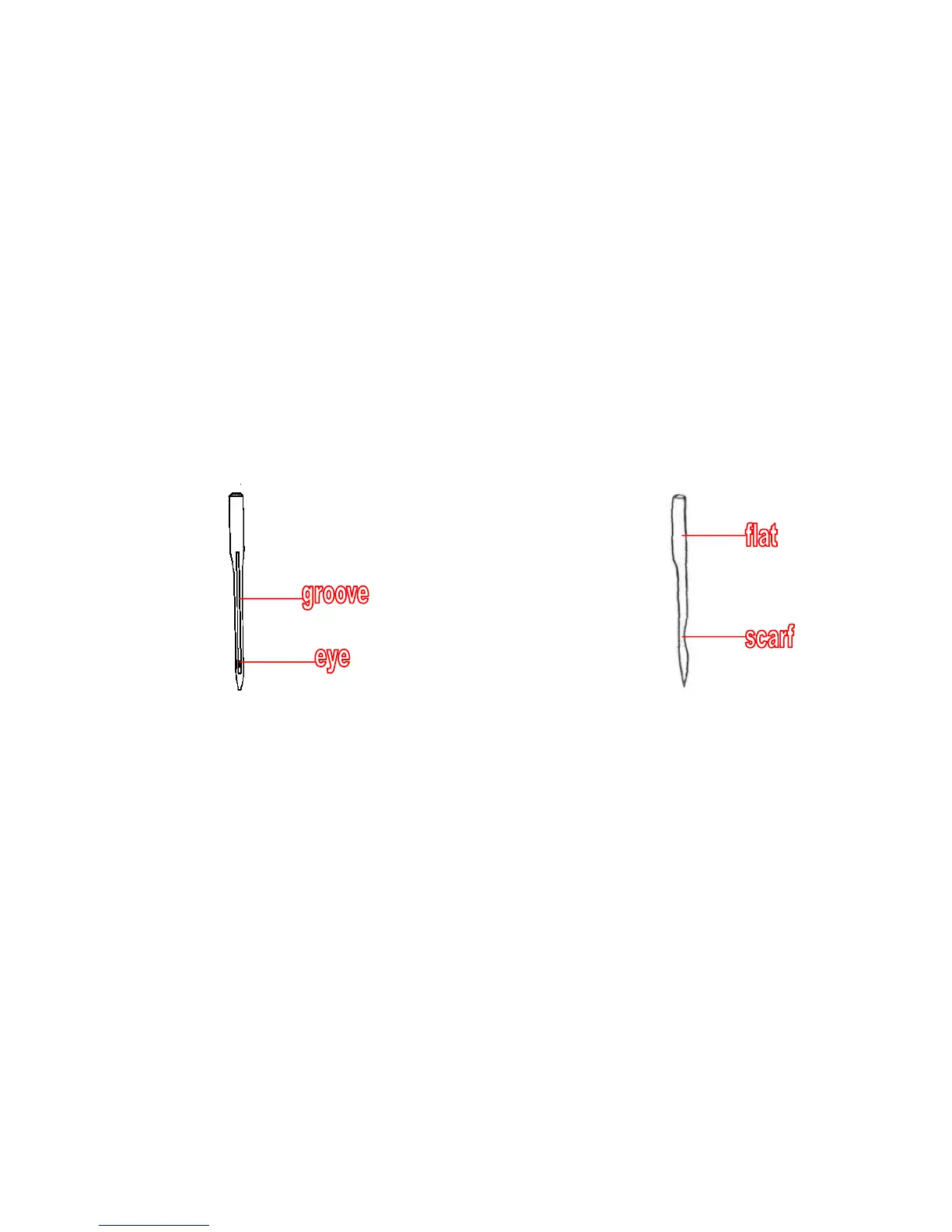

On most machines you install the needle so the flat is to the back of

the machine. Side load machines (bobbin case is inserted on the left

side of the machine) the flat is to the right. On some older Singer

machines the flat is to the left. The needle should be inserted flat to

the back on your machine.

Thread quality and the type of thread being used can be a problem.

Always use good quality thread and try to avoid thread that is old or

knotted. When ever possible use the same thread in the top and

bobbin tensions. Thread the machine as shown in your manual and

make sure the thread is between the tension discs.

If you start with a new needle (inserted properly) and the machine is

threaded as per instructions, sewing problems may be mechanical

breakdown or damaged parts.

Loading...

Loading...