LaserSpeed 9000 Operator Guide

LaserTrak Software

Part No. 93296 / Drawing No. 0921-01419 Page 14 of 16 Revision F (Feb 2013)

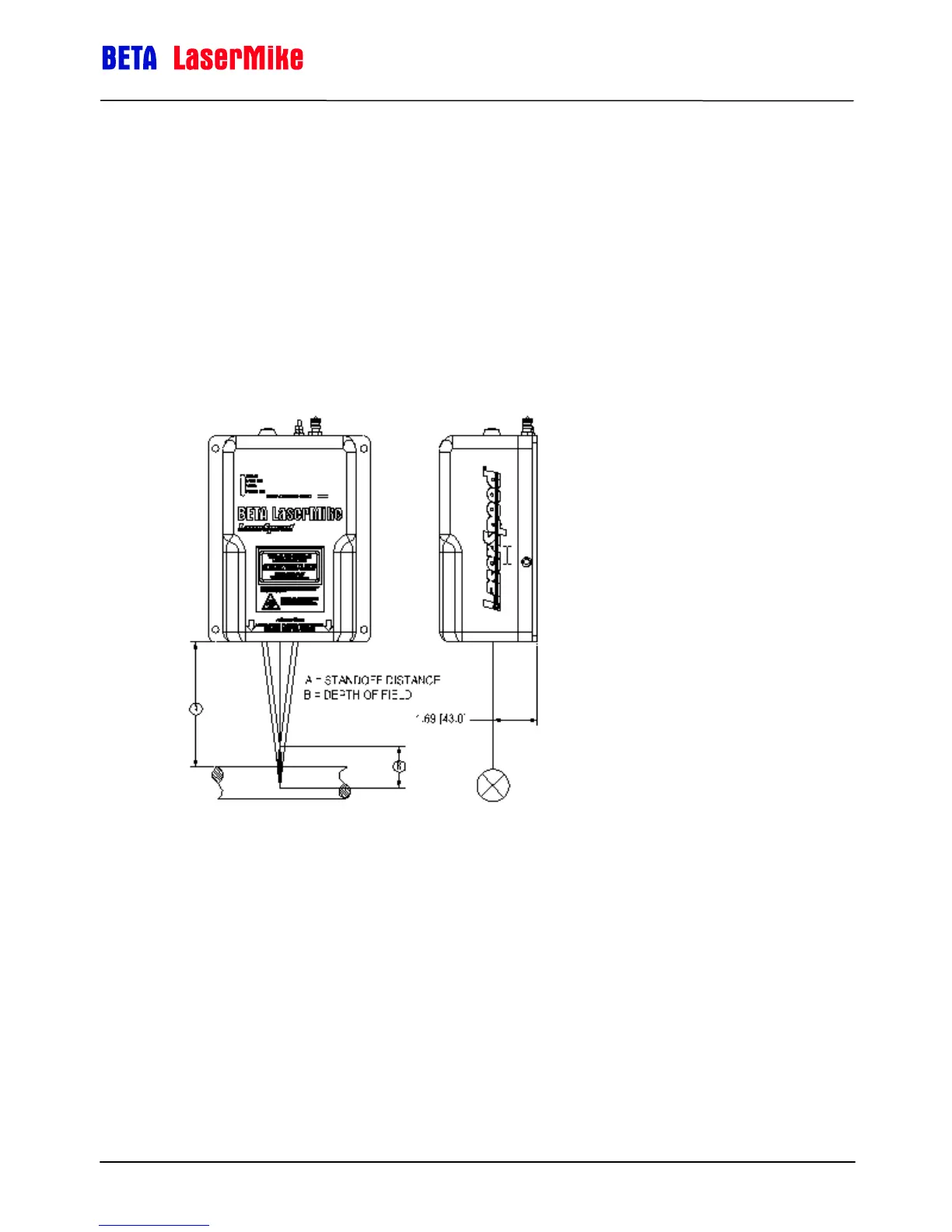

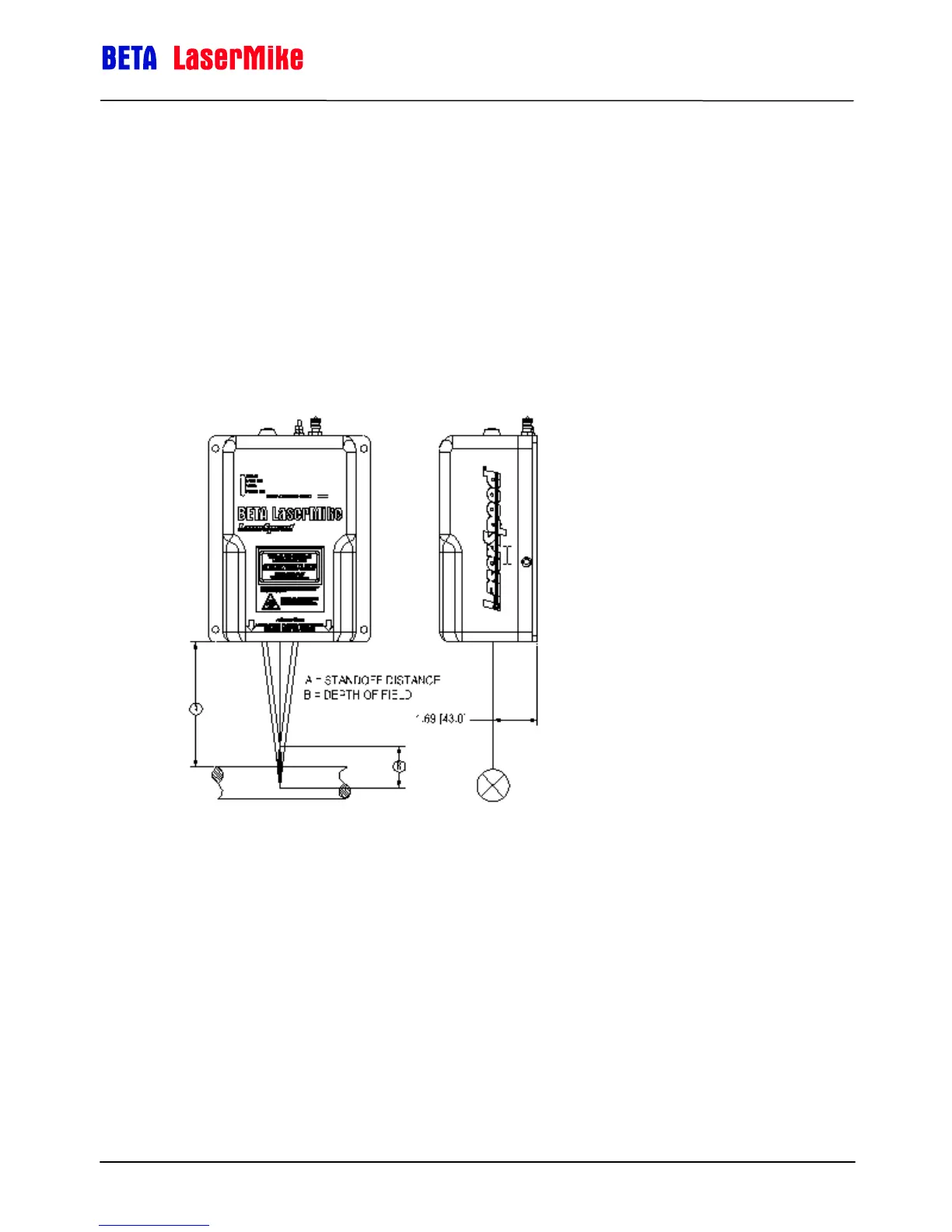

Gauge Alignment

LaserSpeed gauges have a standoff distance and a depth of field the product

needs to stay within in order to make measurements. The last two digits of the

model number indicate the standoff distance. For example model LS9000-303,

the last two digits are 03 meaning 300 mm (11.8 inches). See the LS9000

Instruction Handbook for more details. The 300 mm (11.8 inch) standoff

means the product has to be 300 mm or 11.8 inches from the product. Model

LS9000-303 also has a 37 mm or 1.45 inch depth of field. This means the

product has to be 300 mm (11.8 inches) from the gauge ± 17.5 mm (±0.69

inches).

The laser beam needs to get aligned to the center 20% on round product. For

flat products, the product just needs to be within the depth of field of the

gauge. Normally, the gauge will be aligned perpendicular to the product. See

the LS9000 Instruction Handbook for alignment error if not mounted

perpendicular to the product.

The gauge should be making accurate speed and length measurements once

the gauge has been mounted and aligned properly. The Speed and Length

measurements along with Quality Factor can be monitored using a computer

and the LaserTrak software.

Loading...

Loading...