D-Cell Battery Powered Version:

Size Height Width* Depth**

Inches 5.6 8.4 4.8

Centimeters 14.2 21.3 12.2

*Width includes feet

**Depth with SnapHead pump cartridge in place.

Weight

115VAC/230VAC version: 1.85 lbs/0.84 kg

D-Cell Battery Powered version: 1.57 lbs/0.72 kg*

*D-Cell Battery Powered version without batteries

COMPONENTS

Enclosure

Molded ABS plastic, water-resistant, flame-resistant

Pump

Peristaltic, self-priming and self-checking,

6 Volts DC

Speed & Displacement

Battery-Powered Units: 5.5 oz per min (153 ml per min)*

Line-Powered Units: 7.5 oz per min (222 ml per min)*

*With Silicone tubing. Results may vary depending on voltage,

chemical viscosity, temperature and other factors. Always

perform your own test with your unit to confirm actual pump

speed.

Maximum Duty Cycle

At temperatures up to 85°F/29°C: 4 hours of pump down-time

required for every 20 minutes of continuous run.

At temperatures over 85°F/29°C: 12 hours down-time for every

20 minutes of continuous run time.

Hydraulic Performance

Maximum Vacuum: 8 in of mercury

Maximum Pressure: 20 psi

Tubing Material

Silicone

Viton

Coin Battery

3 Volt Lithium BR2032 or CR2032

Regulatory

CSA CE

DR-2000/115 VAC U.S.

DR-2000/230 VAC E.U.

DR-2000/6V

For confirmation of regulatory compliance, see rating label on

your DR-2000.

INSTALLATION

Refer installation and service to qualified

personnel only.

Installation must comply with all applicable

plumbing and electrical codes.

MOUNTING

The DR-2000 should be mounted so the LCD screen can be

viewed easily. It should be located close enough to both the

injection point and liquid supply to ensure unobstructed

delivery.

1. Align the metal mounting bracket and mount on a smooth

surface using screws.

2. Place the DR-2000 over the mounting bracket and slide it

down tight.

3. If desired, a screw can be placed in one of the feet to hold

the unit in place.

The DR-2000 can also be mounted using the

three plastic feet. If mounting on an uneven

surface, be careful not to over-tighten or snap

the feet off.

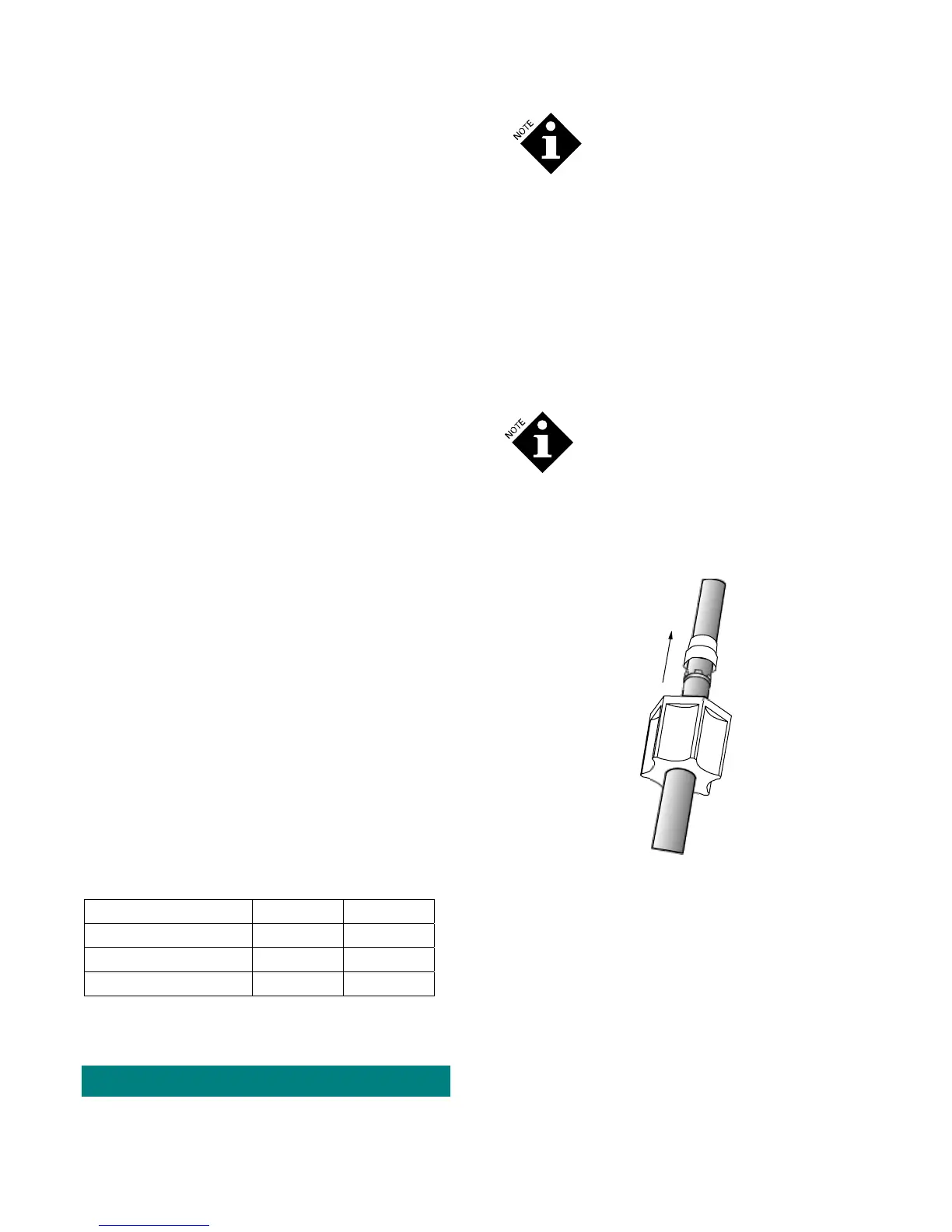

INSTALLING SUPPLY LINES

1. Cut the desired length of 1/4-inch (6mm) chemical feed

line and attach it to the nut of the left side (suction side) of

the pump squeeze tube.

D

R

2

0

0

0

M

F

0

3

Figure 3. Installing the Chemical Feed Line to the

Squeeze Tube Fitting.

2. For the chemical uptake side, a standpipe is provided. Cut

the bottom of the chemical feed line tubing at a 45-degree

angle and press it into the standpipe. Insert the chemical

feed line 0.5 inches (12 mm) above the bottom of the

standpipe. Both the 45-degree cut and the 0.5 inch (12 mm)

distance above the bottom of the standpipe will help avoid

the formation of a seal with the bottom of the chemical

drum and ensure an unobstructed chemical uptake.

2 1210730 DR-2000 (R14735-00, Rev C) February 2010

Loading...

Loading...