SnapHead Pump Cartridge 6 mm 1202706

w/Viton Tube

Silicone Squeeze Tube 1/4 inch 058209

Viton Squeeze Tube 1/4 inch 1201109

Silicone Squeeze Tube 6 mm 1202709

Viton Squeeze Tube 6 mm 1202711

Tube Insert 1/4 inch 036969

Tube Insert 6 mm 1202724

Tube Fitting, Nut 1/4 inch 043823

Tube Fitting, Nut 6 mm 1202723

Tube Fitting Nut 1/4 inch, Pack of 5 092213

Mounting Bracket, Stainless Steel for 087235

115 VAC and 230 VAC

Mounting Bracket, Stainless Steel for 069188

D-cell Battery Unit

Bezel Gasket 1202615

Pump Gasket 099705

Low Level Alarm Buzzer Kit 1202595

w/Strain Relief

Low Level Alarm Lance 1201180

115 VAC Power Cord 087658

Install Kit (non-European versions) 1202593

MAINTENANCE

Safety glasses and protective clothing should

be worn while servicing the DR-2000.

Refer installation and service to qualified

personnel only.

PERIODIC MAINTENANCE

Pump & Squeeze Tube Replacement

Schedule

Since every installation is different (chemicals, tube runs,

operating frequency, and so on), an exact tube replacement

schedule cannot be specified. With use, the tube slowly evolves

from round to oval and the amount of chemical pumped

decreases. By regularly checking the amount of chemical

pumped, you can determine general tube life. It is recommended

that you closely monitor the time it takes the original tube to

reach the end of its flex life, and then establish a replacement

schedule. Replacing tubes at regularly scheduled intervals

ensures more accurate product use and reduces service calls. In

general, short feed lines of a large diameter will improve pump

tube life.

REPLACING PUMP CARTRIDGES

To Remove

1. Turn off power to the unit to ensure that the pump does not

run during maintenance.

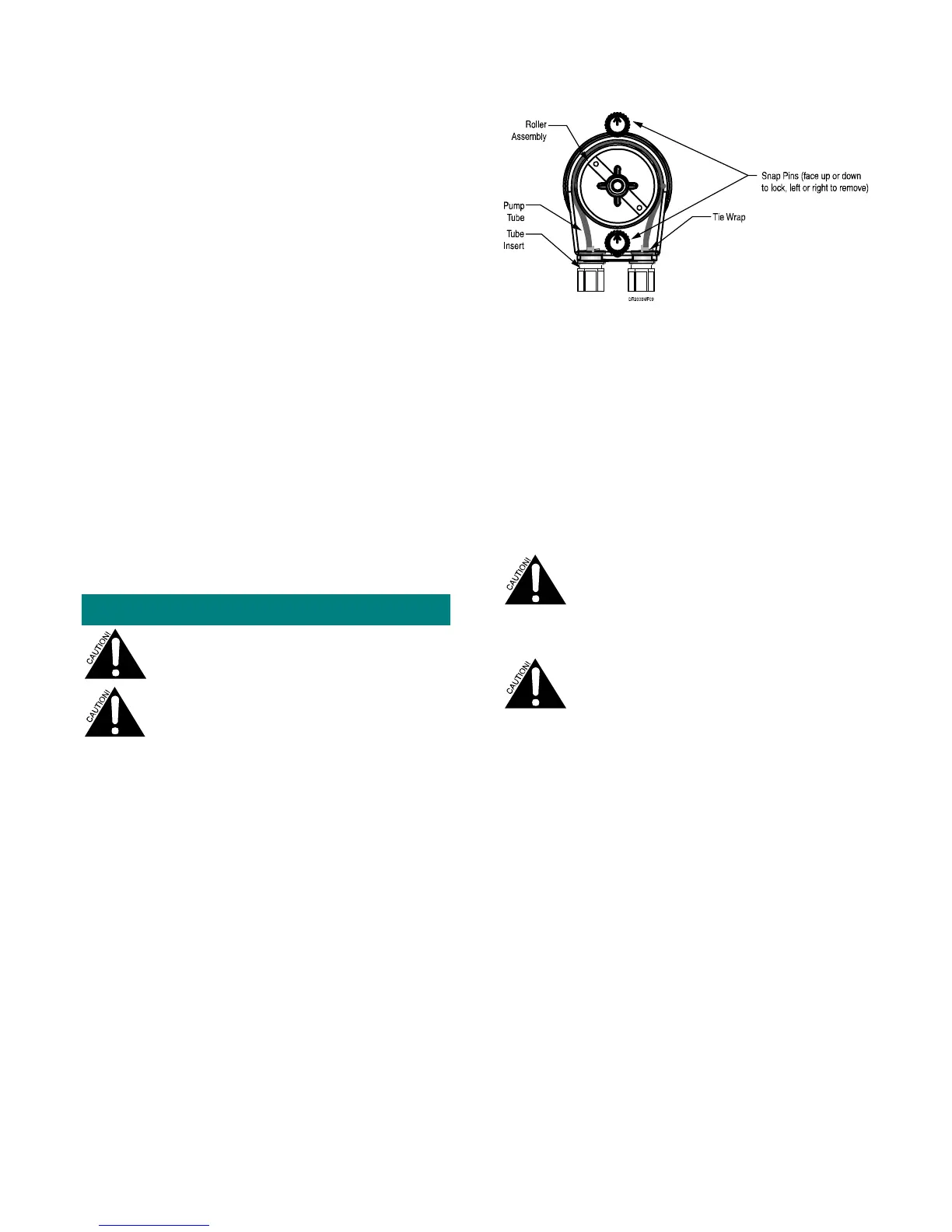

Figure 9. SnapHead Pump Cartridge

2. Turn snap pins to the left or right to remove the pump head.

3. Remove the supply and feed lines from the old pump

squeeze tubing and connect them to the new pump squeeze

tubing.

To Install

1. Align and engage the pump drive spline with the motor

gear by rotating the roller assembly.

2. Turn the snap pins so that the arrow is pointed either

straight up or down. Then push in until you hear a distinct

click.

Replacing Pump Squeeze Tubing

Splash danger! Because the squeeze tube

contains chemical product and is flexible, extra

caution should be taken while changing the

squeeze tube to insure that the chemical does

not splash in the eyes or on the hands or

clothing of the service person.

Always wear protective eyewear, gloves and

protective clothing when changing the squeeze

tube.

1. Remove the cartridge as described above.

2. Loosen but do not remove the small screw at the bottom of

the rear cover and lift the cover from the cartridge.

3. Pull the roller assembly out of the pump cartridge to release

the pump squeeze tubing.

4. Pull the tube inserts out of the pump cartridge.

5. Remove the squeeze tube.

6. Replace it with a new squeeze tube.

7. When using Viton or Silicone, coat the inside of the

cartridge with a liberal amount of Vaseline (petroleum

jelly) lubricant. Never use Dow Corning lubricant with a

Silicone tube, as it will cause it to fail prematurely.

8. Press the two tube inserts into the cartridge so that the tie

wrap "buckles" face toward the center of the pump.

Remember, the tube must not be twisted during the

assembly.

9. Replace the roller assembly.

10. Replace the rear cover and screw.

11. Push the black snap pins back into position, with the arrow

pointing up or down.

6 1210730 DR-2000 (R14735-00, Rev C) February 2010

Loading...

Loading...