SW-Stahl und Werkzeugvertriebs GmbH Tel. +49 (0) 2191 / 46438-0

F 56 essartS resukreveL ax +49 (0) 2191 / 46438-40

ed.lhatsws@ofni :liaM-E diehcsmeR 79824-D

Instruction Manual

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

AIR SOURCE

Clean air of correct air pressure is recommended for the power supply for this tool. A maximum of 90

PSI at the tool is recommended for most air tools of this class. Check specifications section for

recommended pressure. (Depending on length of air hose and other circumstances, air pressure at

compressor may need to be increased to 100 PSI to ensure 90 PSI at the tool.) Water in the air hose

and compressor tank contributes to reduced performance and damage of the air tool. Drain the air

tank and filters before each use and as necessary to keep the air supply dry. Hose length over 25”

causes loss in line pressure. Increase hose ID or increase compressor pressure to compensate

for the pressure loss. Use an in-line pressure regulator with gauge if air inlet pressure is critical.

INSTRUCTION

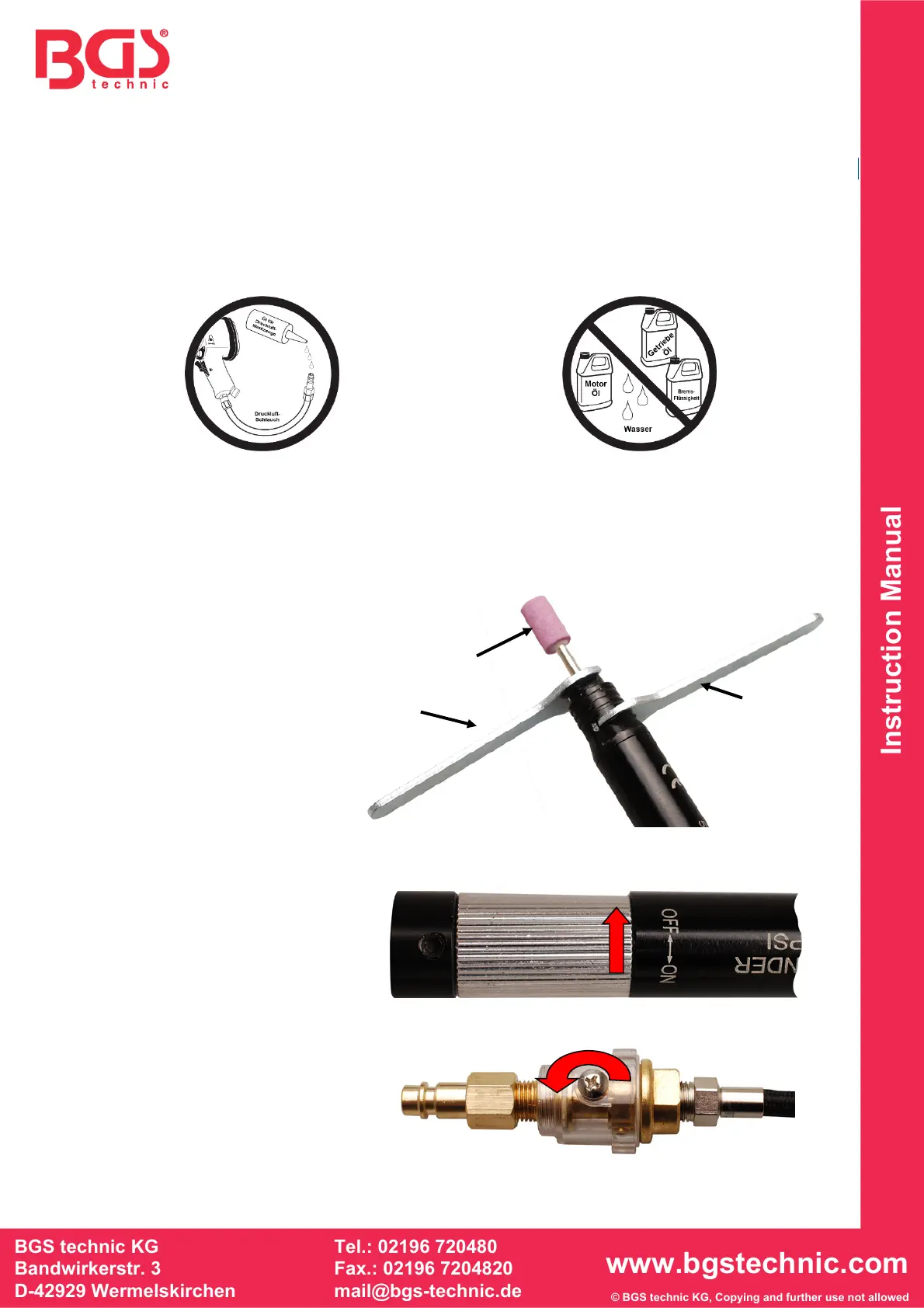

1 Grinding Head

2 Fixing Wrench

3 Counter Holding Wrench

Loosen the chuck as seen in the

figure. Make sure that the shaft is in

the correct position when inserting

the counter holding wrench (3), only

that way the wrench fits.

Take a suitable grinding head (1)

and insert the shaft for approx. 10

mm into the chuck.

Fasten chuck easily with the chuck

wrench (2).

Remove the both wrenches.

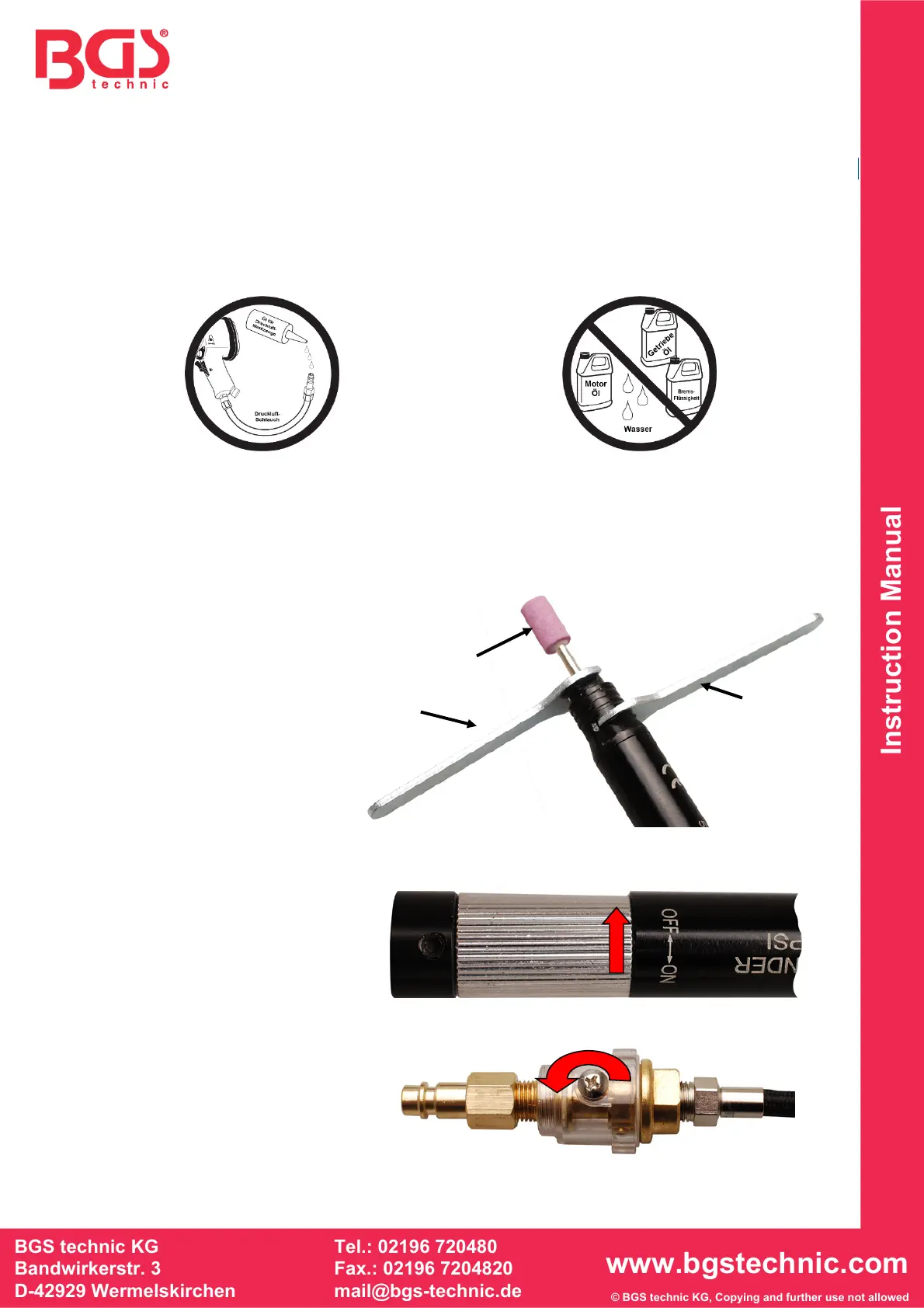

Make sure that the On / Off switch

is in Off position.

Install the compressed air

connection as shown in the figure.

Remove the locking screw and give

a little oil into the oiler.

Install the locking screw and

connect air grinder to compressed

air.

2 3

1

Loading...

Loading...