Modular fan coil unit 2 Installation

Version 2.1 English (17-07-2018)

13

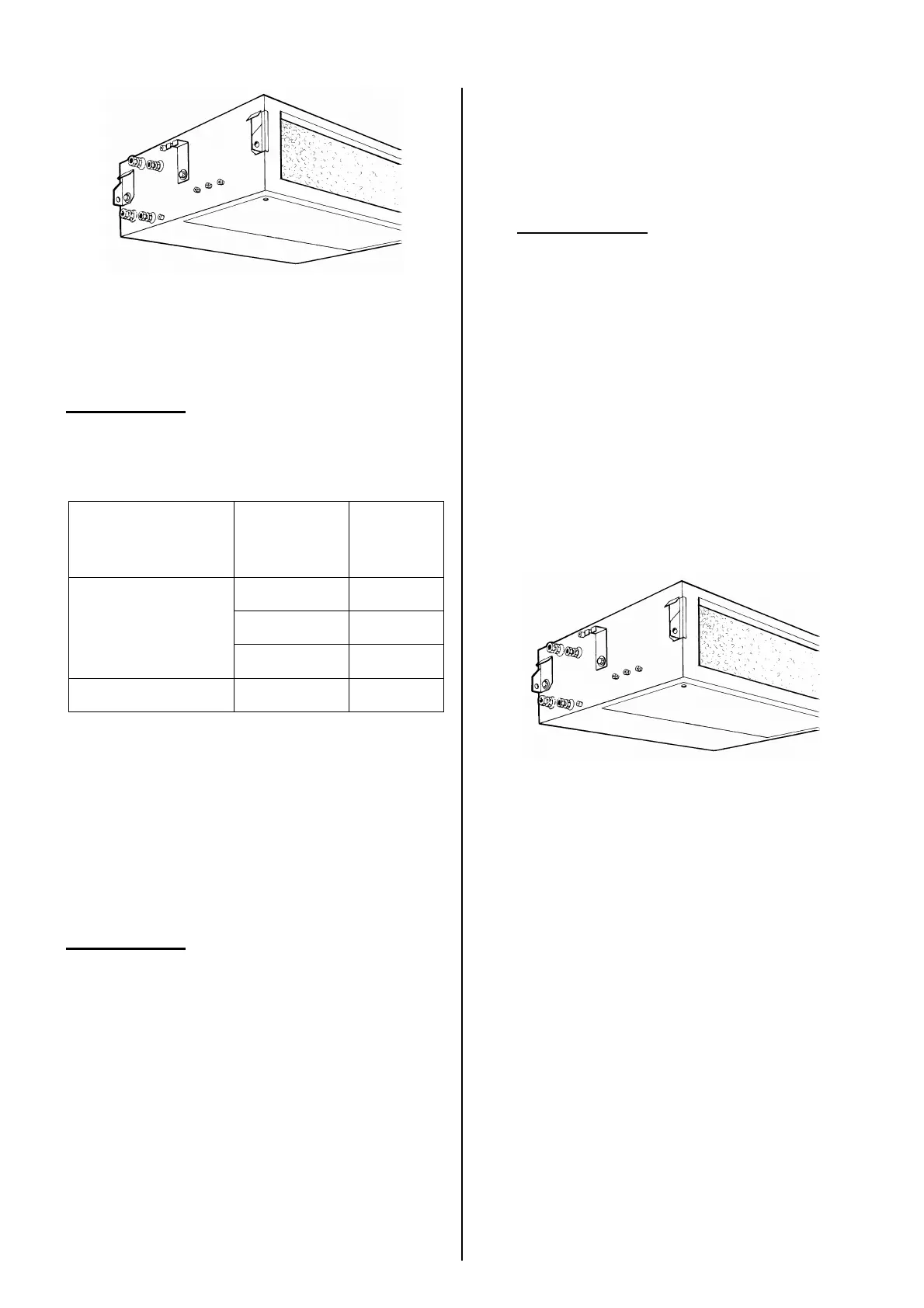

The (1/8") vent cocks 1 are mounted to the

collectors of the heat exchanger, protruding

from the side of the module.

c

Caution:

Biddle recommends the inclusion of a valve

in each pipe.

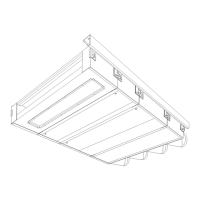

Operating pressure for CH and CW systems

temperature maximum

operating

pressure

< 20° C 16 bar

< 93° C 10 bar

screwed fittings

< 110° C 6 bar

compression fittings all 3 bar

2.9.2 Frost protection

Only for units with ventilation

Depending on the control system, the unit

has a frost protection thermostat or a control-

ler-integrated protection.

c

Caution:

This reduces the risk of the heat exchanger

freezing but does not warrant 100% protec-

tion.

Prevent the heat exchanger from freezing:

- Provide for constant circulation of the

water at the right temperature.

- Add glycol to the water when the unit is

not in operation during the wintertime.

2.9.3 Connecting water pipes

1 Lay the water pipes, and connect them to

the screwed or compression fittings.

c

Caution:

Tighten the compression fittings well.

2 Fill the CH and/or CW system.

3 Vent the heat exchanger.

4 Check the connections for leaks.

2.10 Connecting the

condensate drain

Only for units with cooling

2.10.1 Particulars

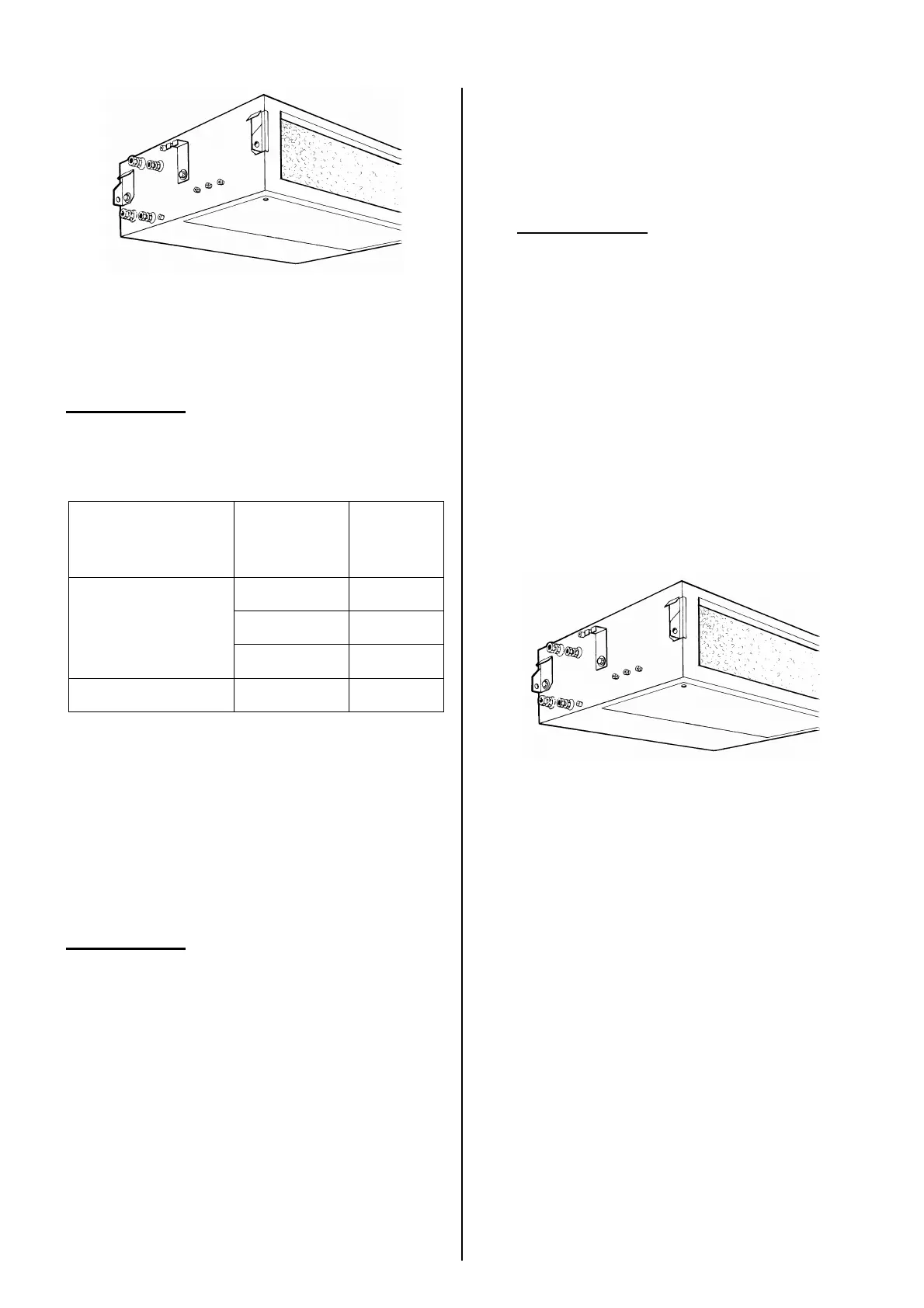

The unit has two (∅ 15mm) condensate wa-

ter drains 2. One of the drains must be fitted

with a stink trap and connected to the sewer.

The second drain is closed with a compres-

sion cap but can be used if necessary.

The unit can be provided with a condensate

drain tray and/or a condensate pump (acces-

sories). If so, their drains must be connected.

2.10.2 Connecting the condensate

drain

1 Install a sewer connection incl. stink trap.

2 Connect the condensate drain tray to a

flexible hose.

3 Connect the hose, with a stink trap, to

the sewer.

4 Insulate the pipes that are not hanging

over the condensate drain tray.

Loading...

Loading...