Modular fan coil unit 2 Installation

Version 2.1 English (17-07-2018)

9

3 Fix the duct sections as you please, e.g.,

by bricking them in or by fixing them with

screws. If using screws, mind their posi-

tions: the screws must not hinder the in-

stallation of the external grille.

n

Note:

Seal any gaps between sleeve and wall in a

draught- and leakage-free manner.

4 Drill the (∅ 5mm) grille fixing holes into

the flanges of the sleeve section that is

fixed to the outer wall.

5 Apply paste onto the inner side of the

grille flanges. The paste is to seal off the

gap between grille and sleeve in a

draught- and leakage-free manner.

6 Fix the grille to the flanges using sheet

metal screws.

c

Caution:

Place the grille with the blades correctly

positioned: oriented outward to allow for run-

off.

2.5 Installing the roof duct

Accessory, only in combination with air valve

module (PS L)

The roof duct is made up of two parts: a roof

curb and a roof cap. The roof cap consists of

a cover and a sleeve. On delivery, these are

attached to one another.

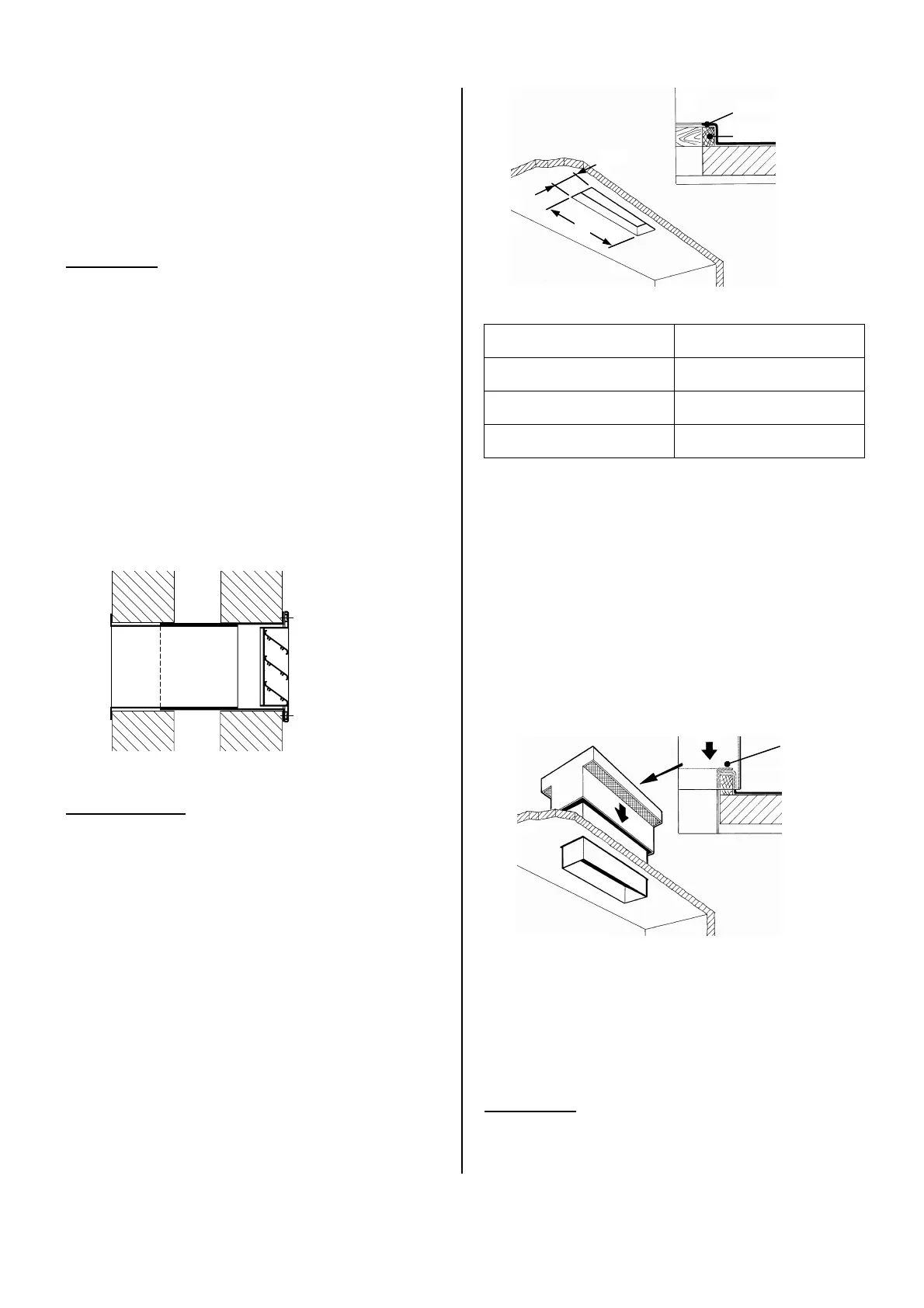

Opening dimensions for roof duct

type opening, A x B

PS 20, 21

628 x 145 mm

PS 40, 41

1003 x 145 mm

PS 60, 61

1503 x 145 mm

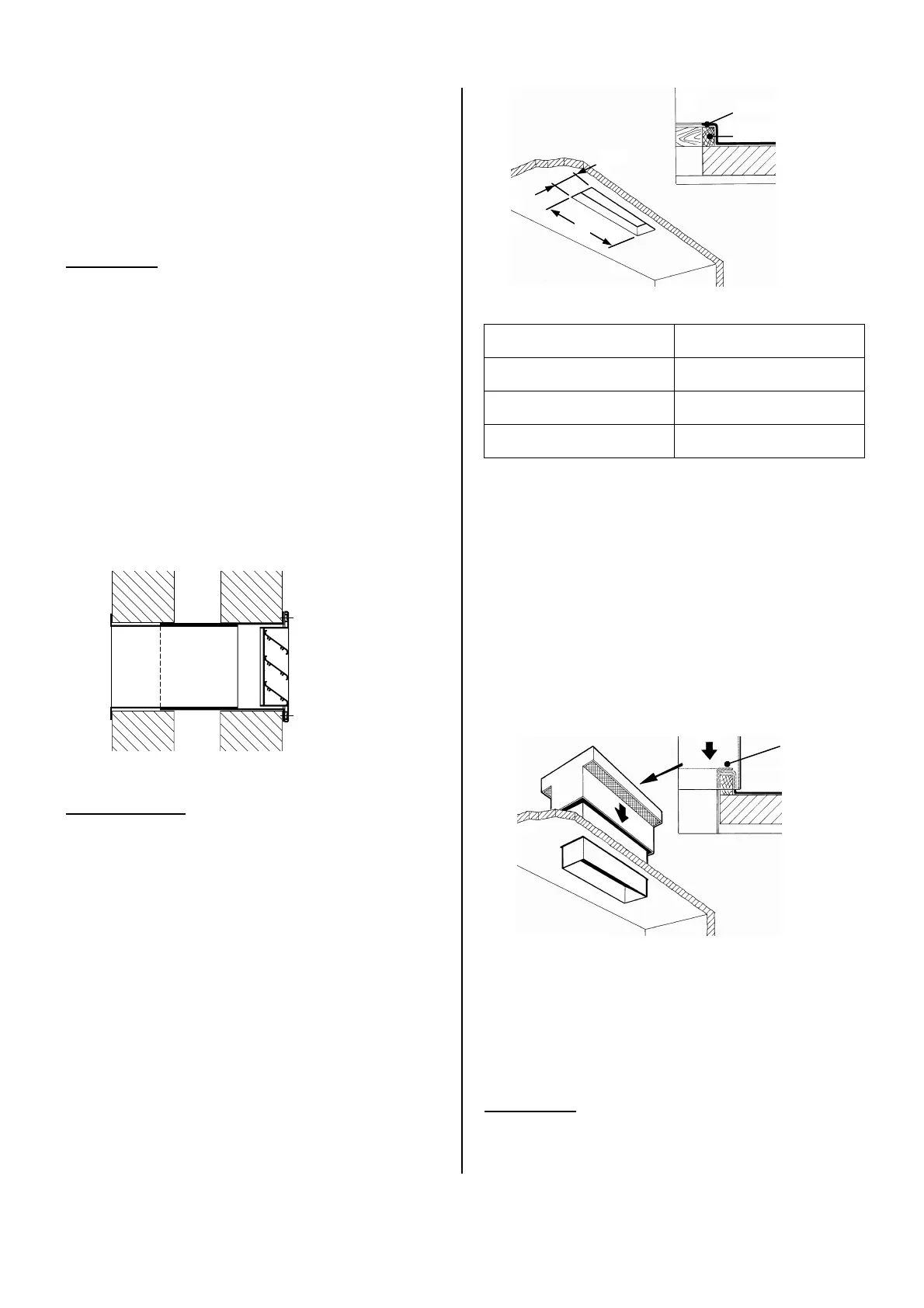

1 Apply the included expanding foam gas-

ket around the ventilation opening of the

air valve module.

2 Make an opening in the roof.

3 Make a water-tight curb 1 around the

opening.

4 Detach the cap from the sleeve. To do

so, loosen the screws in the upper side

of the sleeve.

5 Insert the sleeve into the opening. Con-

nect sleeve and curb by fixing screws 2

through the sleeve’s inner side.

6 Mount the cap to the sleeve.

n

Note:

Seal any gaps between sleeve and roof in a

draught- and leakage-free manner.

A

B

Timber 70x70

Tar mastic

1

2

Loading...

Loading...