81883XPage 10 of 12

TROUBLE SHOOTING

Product discharged from air exhaust.

S Check for diaphragm rupture.

S Check tightness of (6) diaphragm nut or (14) bolt.

Air Bubbles in product discharge.

S Check connections of suction plumbing.

S Check band clamps on intake manifold (nonĆmetallic models).

S Check O" rings between intake manifold and fluid caps.

S Check tightness of (6) diaphragm nut or (14) bolt.

Pump blows air out main exhaust when stalled on either stroke.

S Check U" cups on (111) spool in major valve.

S Check (141) valve plate and (140) insert for wear.

S Check (103) sleeve and (2) O" ring on diaphragm connecting rod.

S Check (119) O" rings on (118) pilot rod for wear.

Low output volume.

S Check air supply.

S Check for plugged outlet hose.

S For the pump to prime itself, it must be mounted in the vertical posiĆ

tion so that the balls will check by gravity.

S Check for pump cavitation Ć suction pipe should be 1/2" minimum or

larger if high viscosity fluids are being pumped. Suction hose must

be nonĆcollapsible type, capable of pulling a high vacuum.

S Check all joints on intake manifolds and suction connections. These

must be airtight.

S Check for sticking or improperly seating check valves.

S If pump cycles at a high rate or runs erratically, check (119) piston

O" rings for wear.

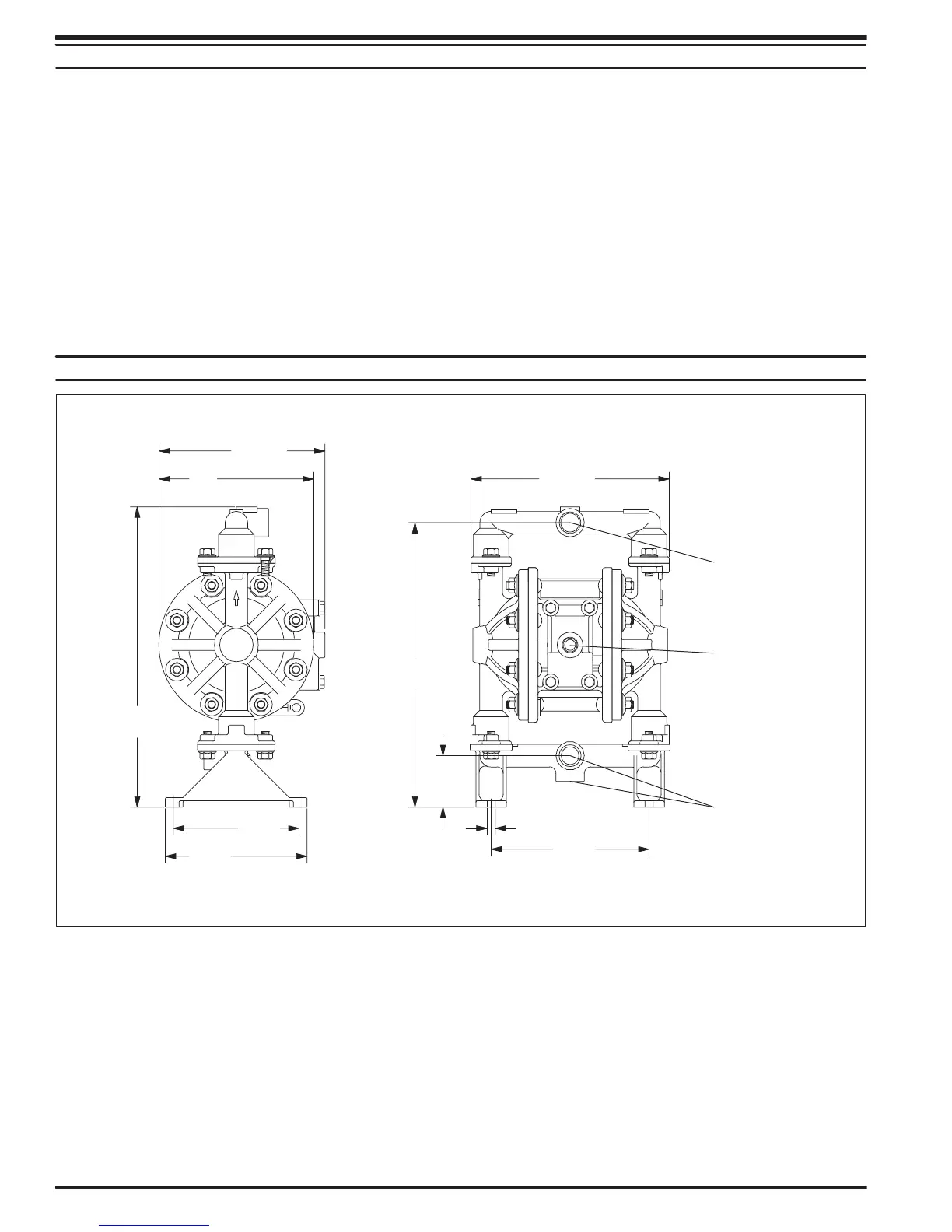

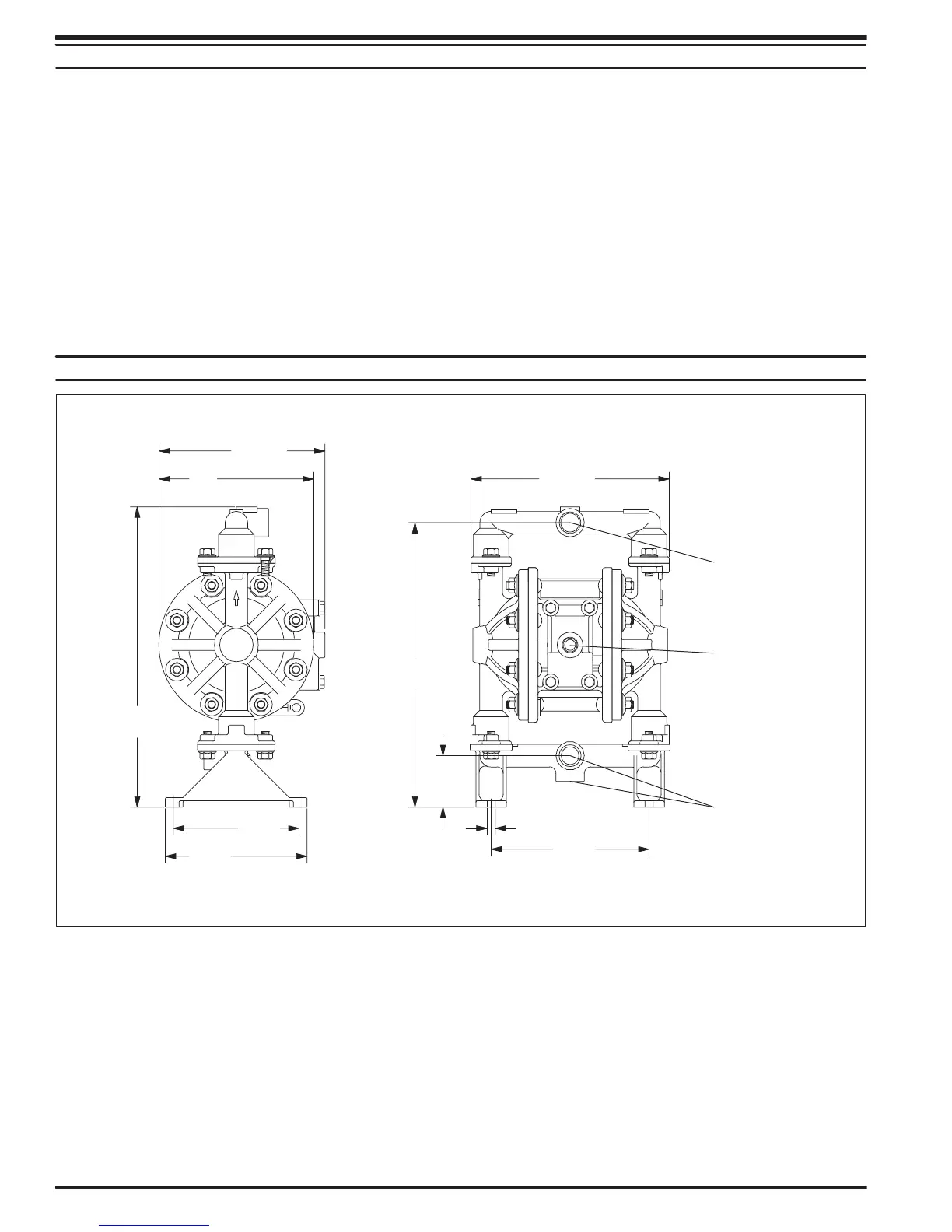

DIMENSIONAL DATA / 818830, 818834, 818837, 818838

Dimensions shown are for reference only, they are shown in inches and millimeters (mm).

4Ć7/8"

(124 mm)

11Ć5/8"

(295 mm)

11"

(279 mm)

5/16" Slot (8 mm)

7Ć11/16"

(195 mm)

6"

(152 mm)

5Ć1/2"

(140 mm)

2"

(51 mm)

6Ć1/8"

(156 mm)

Material Outlet

1/2 Ć 14 N.P.T.F. Ć 1

Air Inlet

1/4 Ć 18 P.T.F. SAE Short

Material Inlet

1/2 Ć 14 N.P.T.F. Ć 1

6Ć7/16"

(164 mm)

Figure 6

Loading...

Loading...