– 30 –

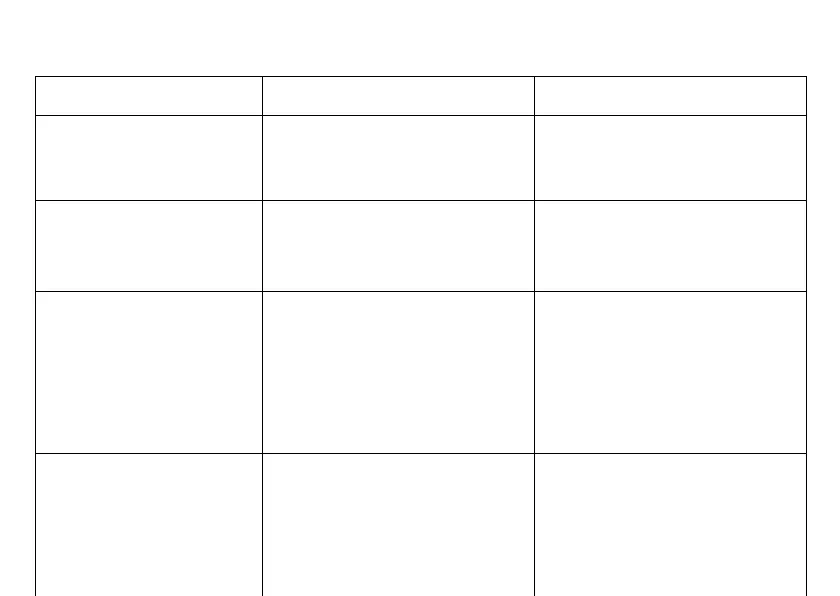

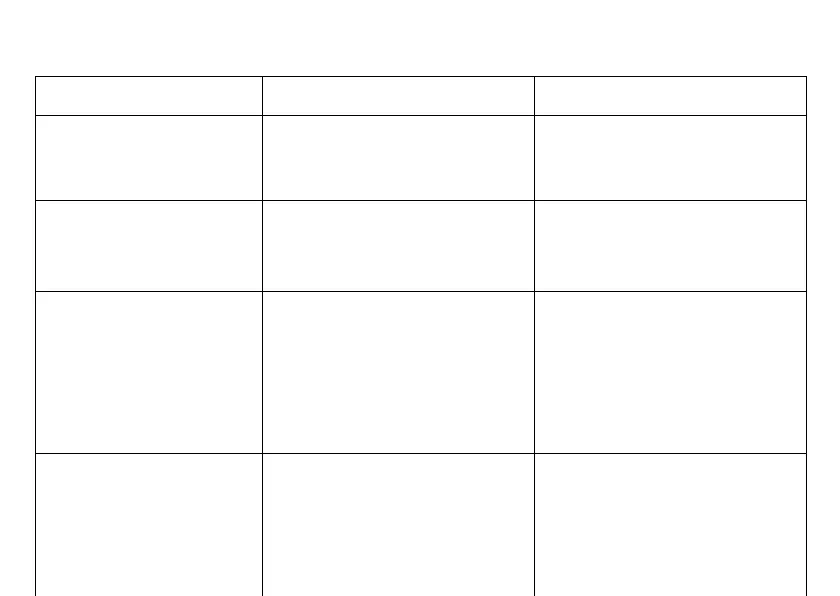

Trouble Shooting

Problem Possible cause Corrective action

Piston diffi cult to move - Formation of crystals, dirty - Stop dispensing immediately. Loose

piston by circular motion, but do

not disassemble. Follow all cleaning

instructions (➤ p. 21-23).

Filling not possible - Volume adjusted to minimum setting

- Set to required volume (➤ page 16).

- Sticking fi lling valve - Clean the fi lling valve. If necessary

replace the valve with sealing washer

(➤ page 24).

Instrument does not

dispense liquid

- Discharge tube closure cap

pushed on

- Remove closure cap.

- Discharge tube not fi rmly

connected or damaged

- Push on the closure cap. Hold the

piston in place, and push the original

manufacturer‘s discharge tube on

fi rmly (➤ page 11). Replace a de-

formed or damaged discharge tube

(➤ Accessories and Spare Parts).

Air bubbles in the instrument - Reagent with high vapor pressure

has been drawn in too quickly

- Slowly draw in reagent.

- Seal not inserted, knurled locking

nuts not fi rmly connected

- Double check that seal (R) is in

place, and that the knurled locking

nuts at the discharge tube are fi rmly

seated and fi nger tight.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...