ENGLISH

6

or removingaccessories.

WARNING: Do not attempt to tighten drill bits (or any

other accessory) by gripping the front part of the chuck

and turning the tool on. Damage to the chuck and

personal injury may occur when changingaccessories.

To Insert a Drill Bit or Other Accessory

1. Grasp the rear half of the chuck

8

with one hand

and use your other hand to rotate the front half

9

in

the counterclockwise direction, as viewed from the

chuckend.

2. Insert the bit or other accessory fully into the chuck, and

tighten securely by holding the rear half of the chuck and

rotating the front portion in the clockwise direction as

viewed from the chuckend.

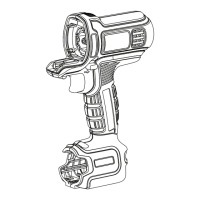

Keyless Chuck (Fig. A)

WARNING: Make certain the lock‑off button is

engaged to prevent switch actuation before installing

Trigger Switch/Reversing Button (Fig. A)

1. The drill is turned ON and OFF by pulling and releasing

the trigger switch

1

.

2. A forward/reverse control button

2

determines the

direction of the tool and also serves as a lock off button.

3. To select forward rotation, release the trigger switch and

depress the forward/reverse control button to the left.

4. To select reverse, depress the forward/ reverse control

button the opposite direction.

NOTE: The center position of the control button locks the

tool in the off position. When changing the position of the

control button, be sure the trigger is released.

OPERATION

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source remove the battery pack before

making any adjustments or removing/installing

attachments or accessories. An accidental start‑up

can causeinjury.

ASSEMBLY AND ADJUSTMENTS

WARNING:

To reduce the risk of serious personal

injury, turn unit off and disconnect it from power

source

remove the battery pack

before making any

adjustments or removing/installing attachments

or accessories. An accidental start‑up can causeinjury.

charging until the battery has reached an appropriate

temperature. The tool then automatically switches to

charging mode. This feature ensures maximum batterylife.

1. A cold battery may charge at a slower rate than a

warmbattery.

2. The hot/cold delay will be indicated by the green

charging LED

6

remainingOFF.

3. Once the battery has reached an appropriate

temperature, the green charging LED

6

will continuously

illuminate, indicating that the tool has resumed the

chargingprocedure.

Electronic Protection System

Li‑Ion tools are designed with an Electronic Protection

System that will protect the battery against overloading,

overheating or deep discharge. The tool will automatically

turn off and the battery will need to berecharged.

Important Charging Notes

1. The tool may become warm to the touch while charging.

This is a normal condition, and does not indicate a

problem. To facilitate the cooling of the tool after use,

avoid placing the tool in a warm environment such as in

a metal shed or an uninsulatedtrailer.

2. If the tool does not charge properly, take the tool and

charger to your local servicecenter.

3. You may charge a partially used battery whenever you

desire with no adverse effect on thetool.

Screw Driving

• For driving fasteners, the forward/reverse control

button

2

should be pushed to the left.

• Use forward/reverse control button

2

pushed to the

right for removing fasteners.

• When moving from forward to reverse, or vice versa,

always release the trigger switch

1

first.

Drilling

• Use sharp drill bitsonly.

• Support and secure work properly, as instructed in the

Safety Instructions.

• Use appropriate and required safety equipment, as

instructed in the Safety Instructions.

• Secure and maintain work area, as instructed in the

Safety Instructions.

• Run the drill very slowly, using light pressure, until

the hole is started enough to keep the drill bit from

slippingout.

• Apply pressure in a straight line with the bit. Use enough

pressure to keep the bit biting but not so much as to stall

the motor or deflect thebit.

• Hold the drill firmly with two hands, one hand on the

handle, and the other gripping the bottom around the

batteryarea.

• DO NOT CLICK THE TRIGGER OF A STALLED DRILL OFF

AND ON IN AN ATTEMPT TO START IT. DAMAGE TO THE

DRILL CANRESULT.

• Minimize stalling on breakthrough by reducing pressure

and slowly drilling through the last part of thehole.

• Keep the motor running while pulling the bit out of a

drilled hole. This will help reducejamming.

Drilling in Wood

• Holes in wood can be made with the same twist drill bits

used for metal or with spade bits. These bits should be

sharp and should be pulled out frequently when drilling

to clear chips from theflutes.

Drilling in Metal

• Use a cutting lubricant when drilling metals. The

exceptions are cast iron and brass which should be

Loading...

Loading...