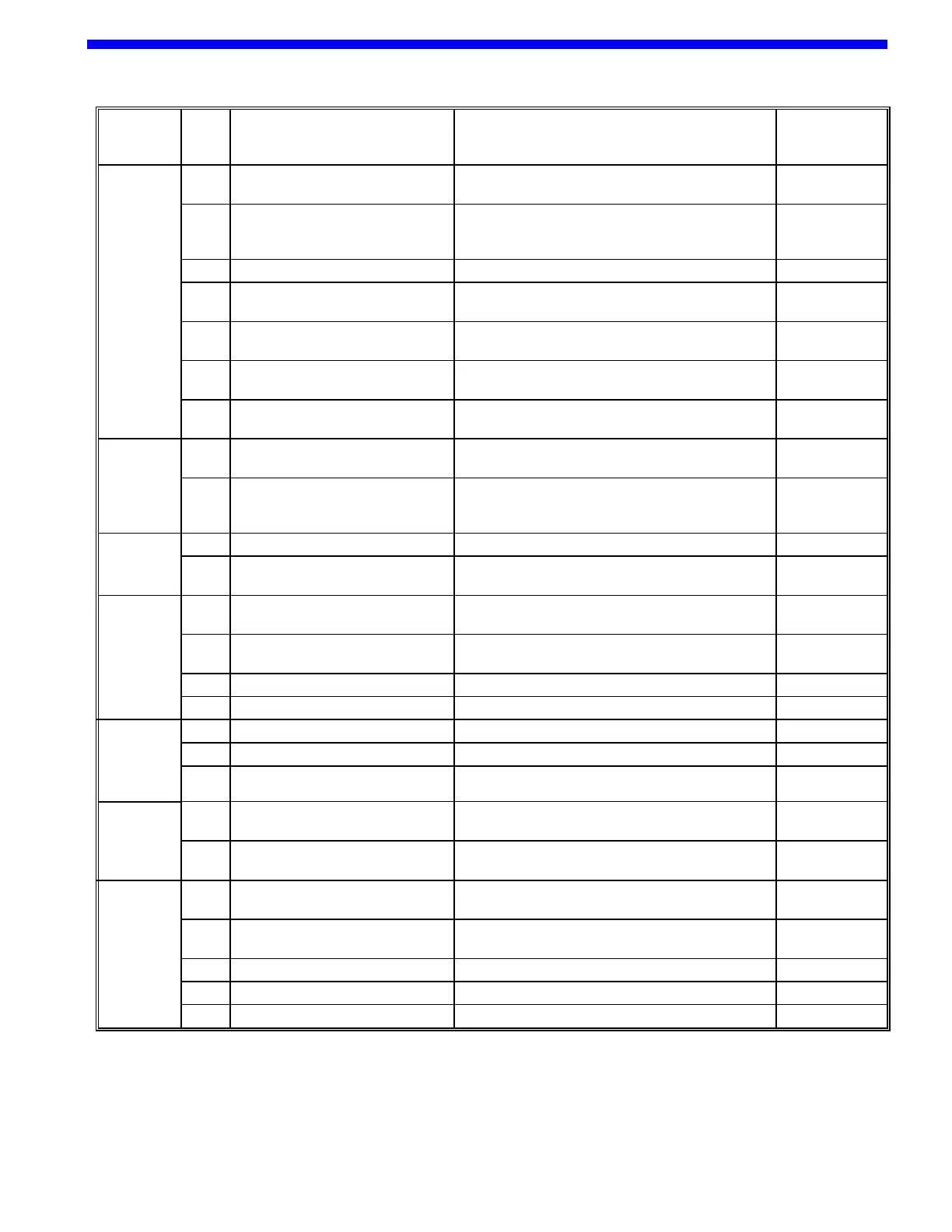

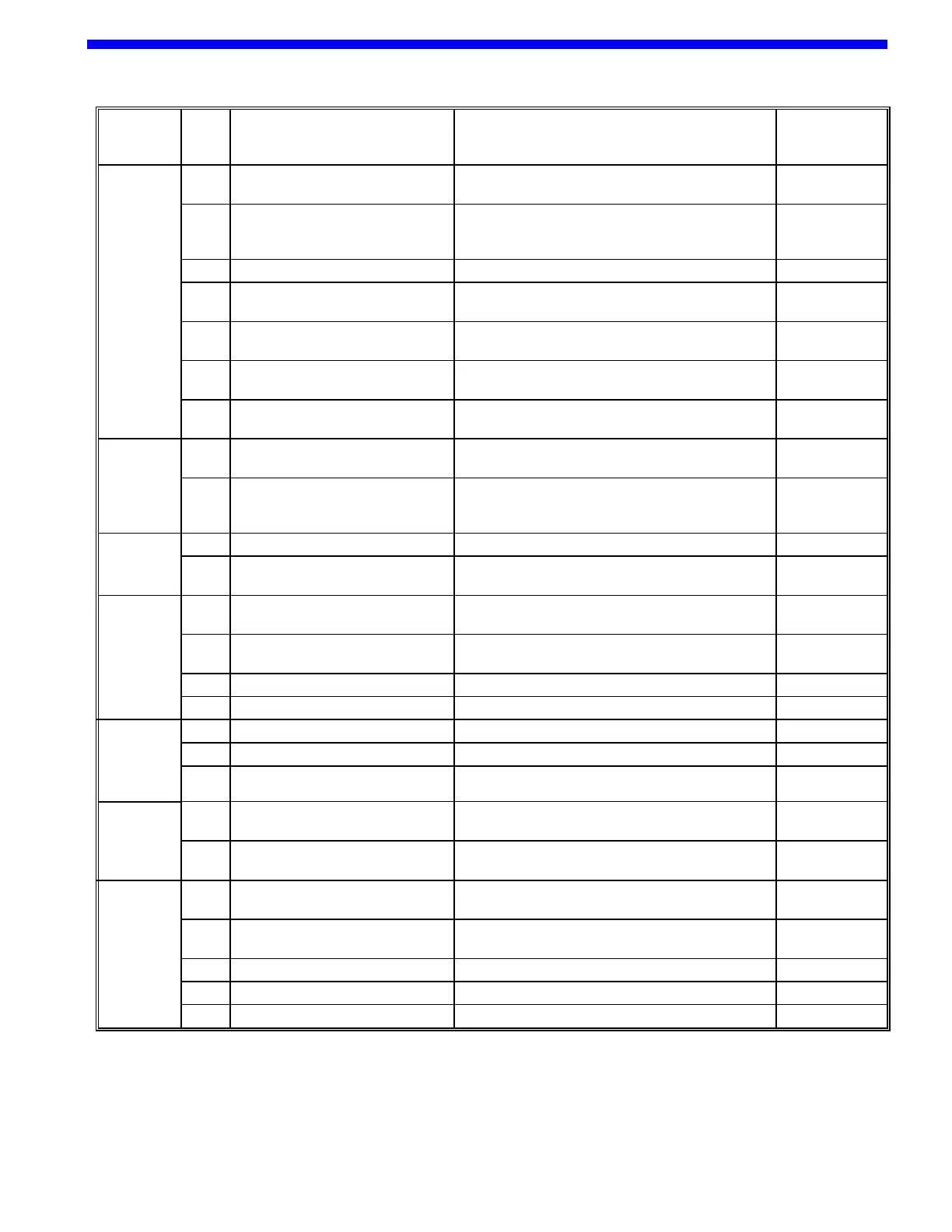

TROUBLESHOOTING

CB5A-021 page 23/24

IF PROBLEM

STILL EXISTS

GO TO STEP ...

4-Way Valve Leaking

(when equipped)

Lubricate with a stick lubricant compatible with

material being transferred.

Worn or Broken Piston Rings

Check condition of rings by restricting discharge

line. If pressure increases slowly, rings are

probably faulty.

Clean screen as necessary.

Remove and inspect for broken or worn springs,

discs, or bodies.

Liquid Relief Valves Need

Adjusting

Adjust per instructions in "Valve Replacement."

Compressor Drive Slipping

Tighten belts, check for sheared keys, loose keys

or loose flywheel.

Piping Improperly Designed or

Installed

Drain liquid trap through drain valve. Relieve

vacuum through bleeder valve on top of liquid trap.

Excess Flow Valves Slugged

Stop the compressor to let the excess flow open.

Installation of a valved bypass line between the

suction and discharge lines may be necessary.

Tighten valve hold-down screws.

Inspect through inspection plates and repair as

necessary.

Oil Pump Relief Valve Not Properly

Set.

Set oil pump relief valve.

Check the Oil Pump drive tab or stop pin for

damage.

Check and fill as necessary

Gas

Leaking

from

Crankcase

Breather

Replace crosshead assemblies and packing.

Improper Seal Arrangement

Valve Closed Downstream of the

Compressor

Line Blockage Downstream of the

Compressor

Locate Blockage and Correct

Loose/Broken Mounting or Anchor

Bolts

See “Mounting the Compressor Unit“

Ensure base is supported full length. See

"Mounting the Compressor."

Improperly Aligned V-belt Sheaves

Improperly Installed Flywheel

See "Compressor Flywheel"

Replace or repair valves.

Loading...

Loading...