960474

INSTRUCTIONS CB5A-021

Installation, Operation, and Maintenance Instructions

Section

Effective

Replaces

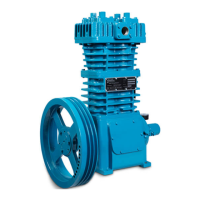

LB162B, LB362D, LB602C,

& Discontinued LB602B, LB362C

r130716

TABLE OF CONTENTS

Safety Data ............................................................. 1

General Information

Compressor Data ............................................... 2

Nameplate Data ................................................. 3

Maximizing Compressor Life .............................. 4

Installation

Location and Piping ............................................ 5

Mounting the Compressor Unit ........................... 5

Stationary Compressors ..................................... 5

Truck Mounted Compressors ............................. 5

Compressor Flywheel ........................................ 6

V-Belt Drive ........................................................ 6

PTO Drive .......................................................... 6

Liquefied Gas Transfer Piping Schematic .......... 7

Typical Transfer Compressor, Drawing .............. 7

Relief Valves ...................................................... 8

4-Way Valves ..................................................... 8

Liquid Traps ....................................................... 8

Temperature and Pressure Switches ........... 8 & 9

Pressure Gauges ............................................... 9

Operation

Pre-Startup Check List ......................................... 9

Start Up Procedure ............................................. 10

Maintenance

Service Schedule................................................ 11

Tool List .............................................................. 12

Bolt Torque Table ............................................... 12

Crankcase Lubrication ........................................ 13

Setting the Oil Pressure ...................................... 13

Compressor Disassembly ..................................... 14

Compressor Assembly .......................................... 15

Valve Replacement ................................................ 17

Seal (Packing) Replacement ................................. 19

S3R Seal Replacement .......................................... 20

Bearing Replacement ............................................ 21

Oil Pump Replacement .......................................... 22

Extended Storage .................................................. 22

Troubleshooting ..................................................... 23

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the product, or in the

manual, look for one of the following signal words and

be alert to the potential for personal injury or property

damage.

Warns of hazards that WILL cause serious personal

injury, death or major property damage.

Warns of hazards that CAN cause serious personal

injury, death or major property damage.

Warns of hazards that CAN cause personal injury, or

property damage.

NOTICE

Indicates special instructions which are very important

and must be followed.

NOTICE

Blackmer compressors MUST only be installed in

systems which have been designed by qualified

engineering personnel. The system MUST conform to

all applicable local and national regulations and safety

standards.

These instructions are intended to assist in the

installation and operation of Blackmer compressors and

MUST be kept with the compressor.

Blackmer compressor service and maintenance shall

be performed by qualified technicians ONLY. Service

and maintenance shall conform to all applicable local

and national regulations and safety standards.

Thoroughly review this manual, all instructions and

hazard warnings, BEFORE performing any work on

the compressor.

Maintain ALL system and compressor operation and

hazard warning decals.

For handling liquefied gas, NFPA Pamphlet 58 should

be consulted.