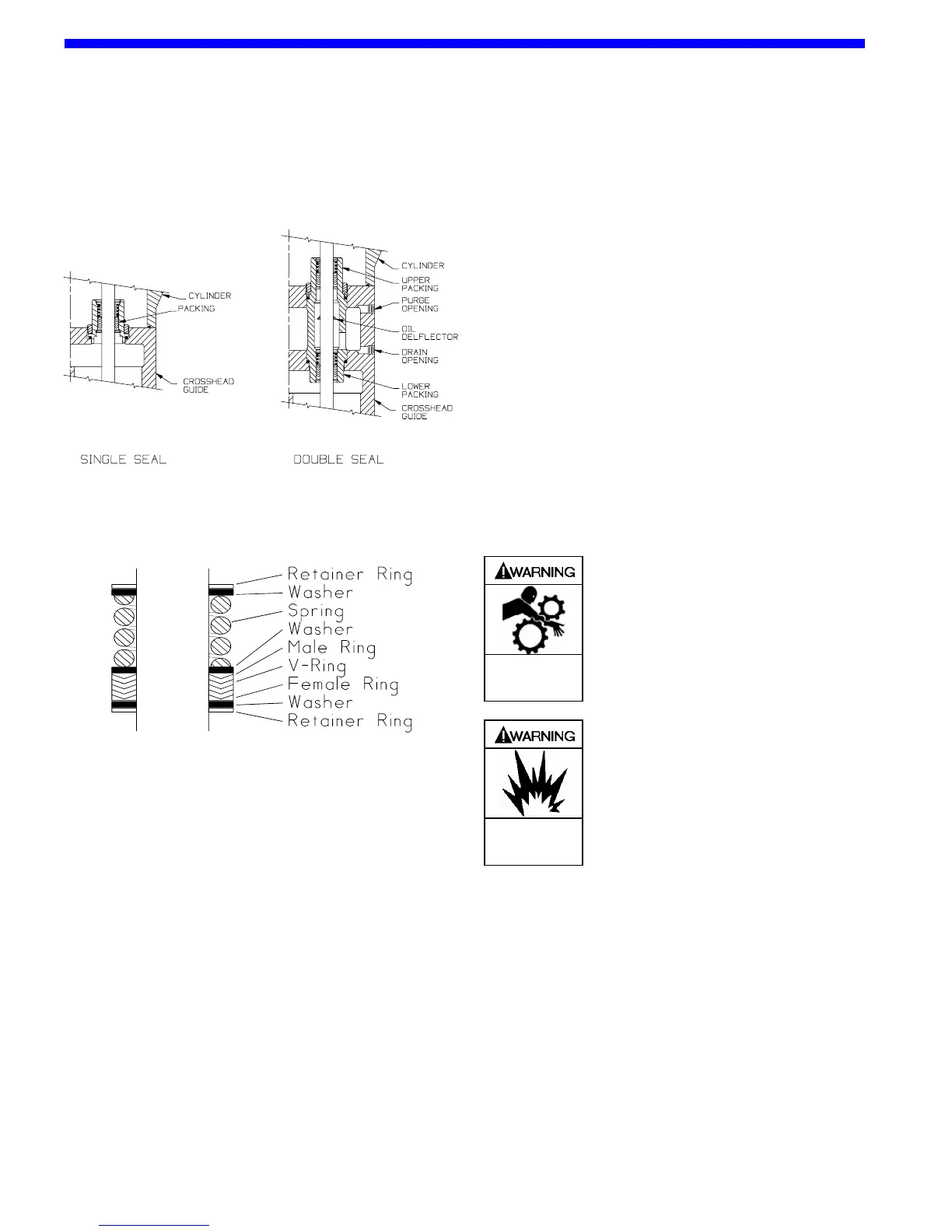

SEAL (PACKING) REPLACEMENT

588/A page 18/24

Follow steps 1 through 6 of the "Compressor

Disassembly" section of this manual.

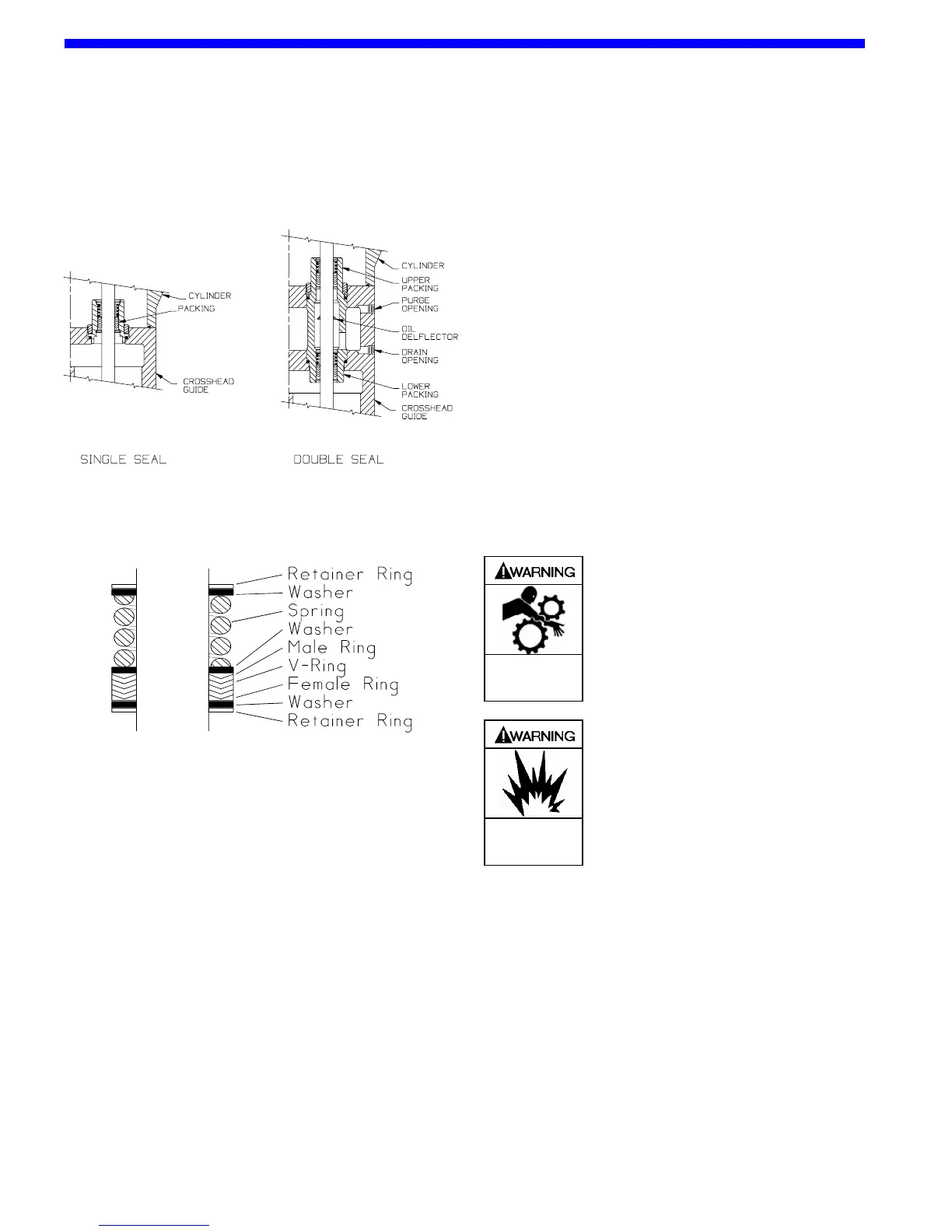

1. Remove the upper and lower retainer ring from the

packing box being serviced. Disassemble the

packing box and discard the old packing sets and

packing springs.

2. Clean the packing box in a suitable solvent. Inspect

the bore for wear, roughness, or corrosion. Clean

or replace as necessary.

3. Ensure that the 6

th

digit of the Compressor ID

number is a "1", indicating a TYPE 1 packing

arrangement. See "Nameplate Data" in this

manual. Refer to Figures 12 and 13 for proper

TYPE 1 component location and orientation.

4. Single-Seal Packing Boxes

a. Install the lower retainer ring.

b. Install the packing rings, spring, washers, and

the upper retainer ring. To ease installation on

the second retainer ring, use a screwdriver

handle and press on the last washer to

compress the seal spring slightly.

5. Two-Seal Packing Boxes

a. Install the inner retainer ring of the lower

packing.

b. Install the packing rings, spring, washers, and

the second retainer ring. To ease installation

on the second retainer ring, use a screwdriver

handle and press on the last washer to

compress the seal spring slightly.

c. Insert the oil deflector ring through the top of

the packing box, flat side down, into the cavity

between the upper and lower packing. The oil

deflector ring will be positioned between the

two sets of packing.

d. Install the upper packing set starting with the

inner retainer ring.

6. The lower packing MUST be manually lubricated

with oil several times during the first 60 minutes of

compressor operation to prevent overheating of the

piston rods and potential damage to the packing

material.

To lubricate the packing:

a. Remove the inspection plate from the

crosshead guide.

b. Stop the compressor approximately every 5

minutes to allow adequate cooling of the piston

rods.

c. Using a small oil can, lubricate the piston rods

each time the compressor is stopped.

Hazardous

machinery can

cause serious

r

n

l in

r

.

DO NOT INSERT OBJECTS OR

FINGERS IN INSPECTION CAVITY.

CAN CAUSE SEVERE PERSONAL

INJURY

Hazardous gases

can cause property

damage, personal

in

r

r

th

IMPROPER SEAL INSTALLATION

COULD RELEASE EXPLOSIVE GAS TO

THE ATMOSPHERE CREATING AN

EXPLOSION HAZARD, POSSIBLY

CAUSING SEVERE PERSONAL INJURY

OR DEATH.

7. Proceed according to steps 5 through 15 of the

"Compressor Assembly" section.

Figure 13 - TYPE 1 Seal Orientation

Figure 12 - Typical Seal Assembly

Loading...

Loading...