EN

4

Head Assembly (H)

! BEFORE STARTING ASSEMBLY!

Many of the major sub-assemblies of the Blade Fusion 480 kit have been pre-assembled at the factory. These sub-assemblies

were not assembled with thread-locking compound. Prior to beginning assembly of the kit, loosen any pre-assembled

screws which are threaded into metal components and apply thread-locking compound. Use only enough thread-locking

compound to moisten the threads. Check all pre-assembled components to ensure all fasteners are tight.

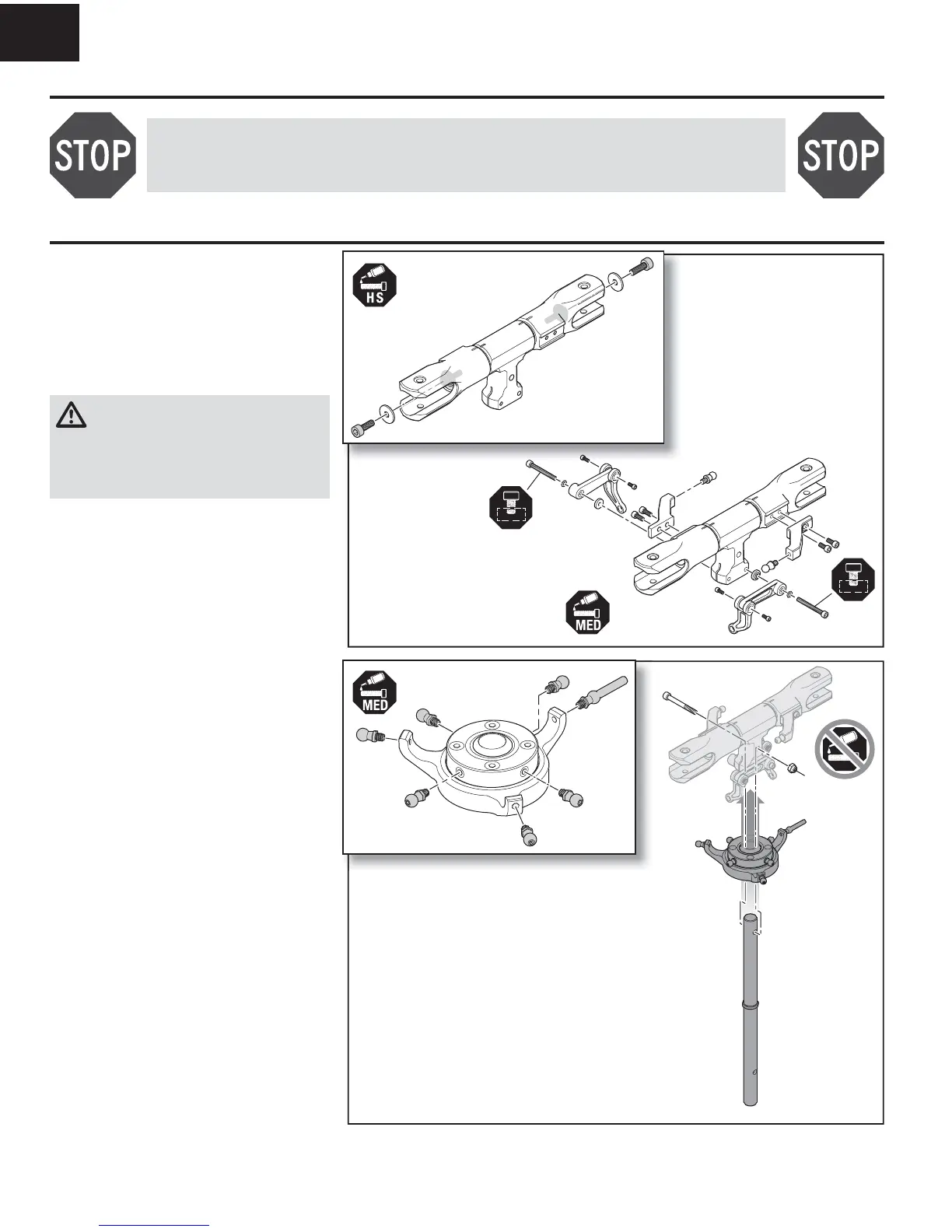

1. Remove the spindle bolts from the blade grips.

2. Clean the spindle threads and the threads of the

4x12mm spindle bolts with isopropyl alcohol.

3. Apply high strength thread-locking compound and

re-install the spindle bolts. Ensure the thread-locking

compound does not contact the blade grip bearings.

WARNING: Failure to apply high strength

thread-locking compound to the spindle bolts

may allow the spindle bolts to work free during

operation, which could cause the rotor blades to fl y

off. Projectile rotor blades pose a serious risk of

property damage and may cause severe bodily injury.

4. Remove the linkage balls from the main grip arms

and re-install them using medium thread-locking

compound.

5. Install the main grip arms to the blade grips using

two 3x10mm socket head caps crews per arm and

medium thread-locking compound.

6. Remove the 2x5mm socket head cap screws one

at a time from the follower arms and re-install with

medium thread-locking compound.

7. Install the follower arms to the head block using one

3x20mm socket head cap screw and two washers

per arm and medium thread-locking compound.

Ensure the thread-locking compound does not

contact the bearings of the follower arms. Do not

fully tighten at this time.

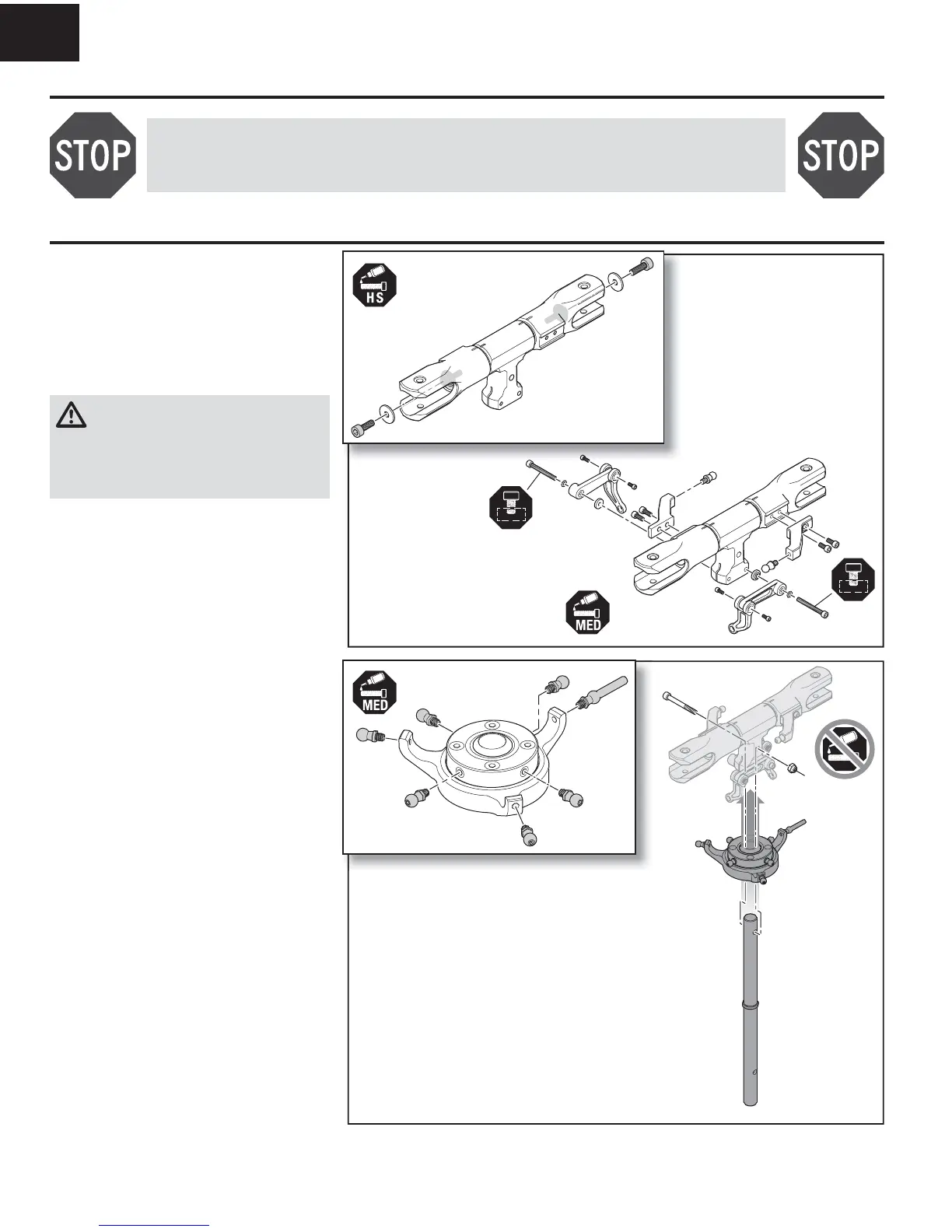

1. Remove the seven linkage balls from the swashplate

assembly one at a time and re-install them with

medium thread-locking compound.

2. Fit the swashplate over the main shaft.

3. Insert the main shaft into the head block and secure

it with a 4x20mm bolt and locknut. Before tightening

the bolt pull on the head block to verify the bolt

passes through the hole in the main shaft. Do not

use thread-locking compound on the head bolt

and locknut.

4. Fully tighten the two follower arm 3x20 socket head

cap screws installed in step 7 above.

Step H2

Step H1

Loading...

Loading...