Operating Instructions BMP-E165

Section 9 - Troubleshooting April 2006

©Blastrac April 2006

44

Before beginning any repair or maintenance work on the

machine or its drives, ensure that it cannot be switched on

accidentally. Set the machine into the “Maintenance Mode”.

See Section 1.7 “Maintenance Mode”.

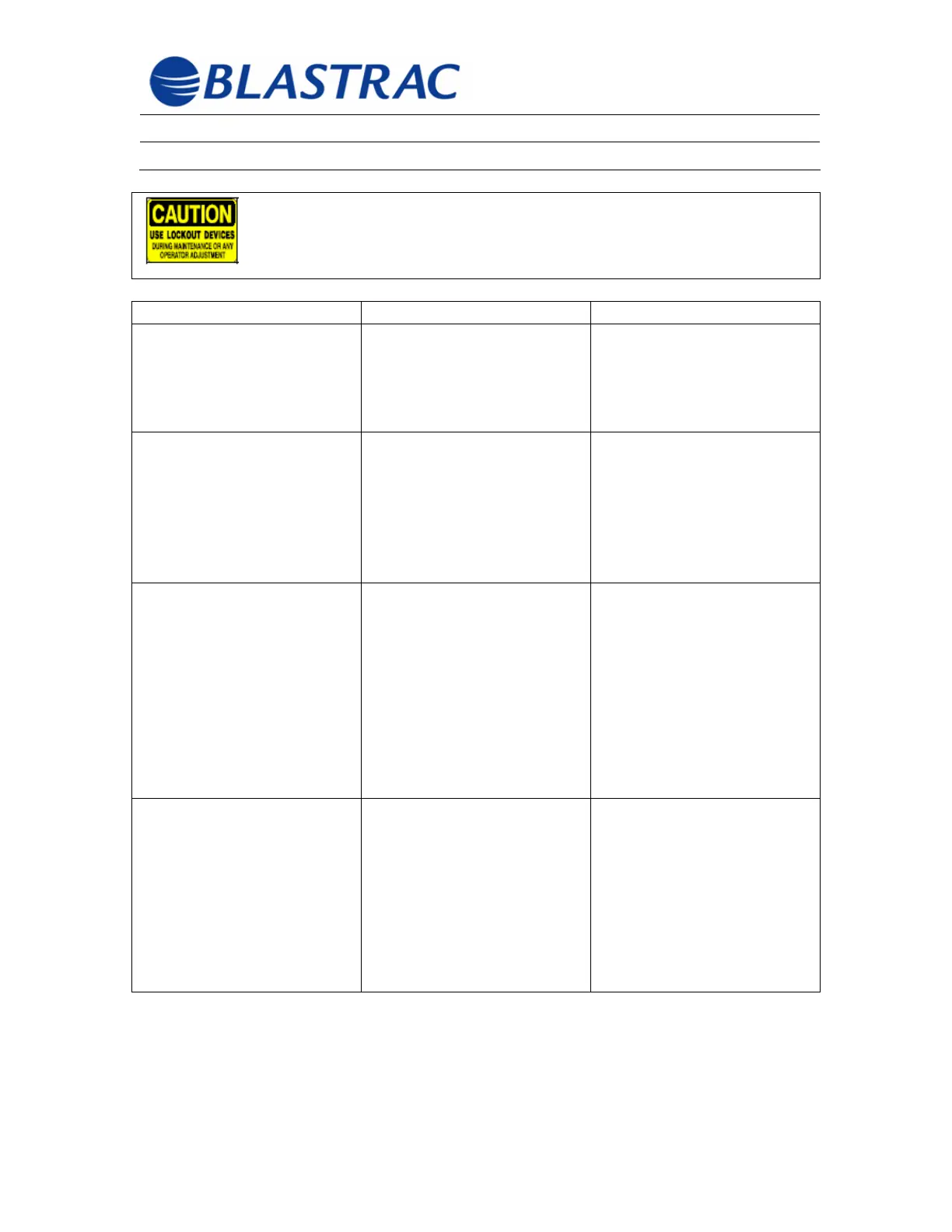

FAULT POSSIBLE CASUE REMEDIES

Excessive Vibration

Unbalanced drum

Defective bearing

Replace worn and/or

broken scarifier cutters

Check drive shaft bearing

and replace if necessary

Unusual noise Defective bearing

Incorrect tension of gear

belt

Defective motor

Check drive shaft bearing

and replace if necessary

Check gear belt tension

and alter if necessary

Replace motor

Controller cannot be

switched on

NOTE: Only a qualified

electrician should

troubleshoot the

machine

Main power connection

not properly connected

E-stop button depressed

Supply voltage under

voltage threshold

Check main connection

and switch on again

Pull E-stop button out

Correct low voltage

problem or find alternate

power supply

Motor does not start

NOTE: Only a qualified

electrician should

troubleshoot the

machine

Electric – Motor fault

If proper power is being

presented to the motor,

the motor windings are

open, shorted or

grounded and the motor

must be repaired or

replaced. Use only an

authorized motor shop to

repair motor

Loading...

Loading...