BL6-U Parallel Integrated Controller Quick Commissioning User Manual

14

5 Motor Initial Angle Tuning (Only for Synchronous Machine)

For machines without attached steel rope and no load, please follow section 1 “Motor Initial

Angle Tuning with no load”. For machines attached with steel rope and have load, please follow

section 2 "Motor Initial Angle Tuning with load".

(The two angle tuning modes can achieve the same effort. Please choose one of them according

to the actual situation.)

5.1 Motor Initial Angle Tuning with no load

Please set PG type F8-02 correctly, set AutoTuneModeSel FC-13 to 0 before perform Motor

initial tuning with no load (Do not attach steel ropes). Procedures required before tuning:

1) Ensure synchronous motor (traction machine) has no load (DO NOT attach steel ropes);

2) Connect running contactor output Y1 (J1-4) and COM1 (J1-5) to make it close;

3) Connect brake contactor output Y0(J1-3) and COM3 (J1-5) to release the brake;

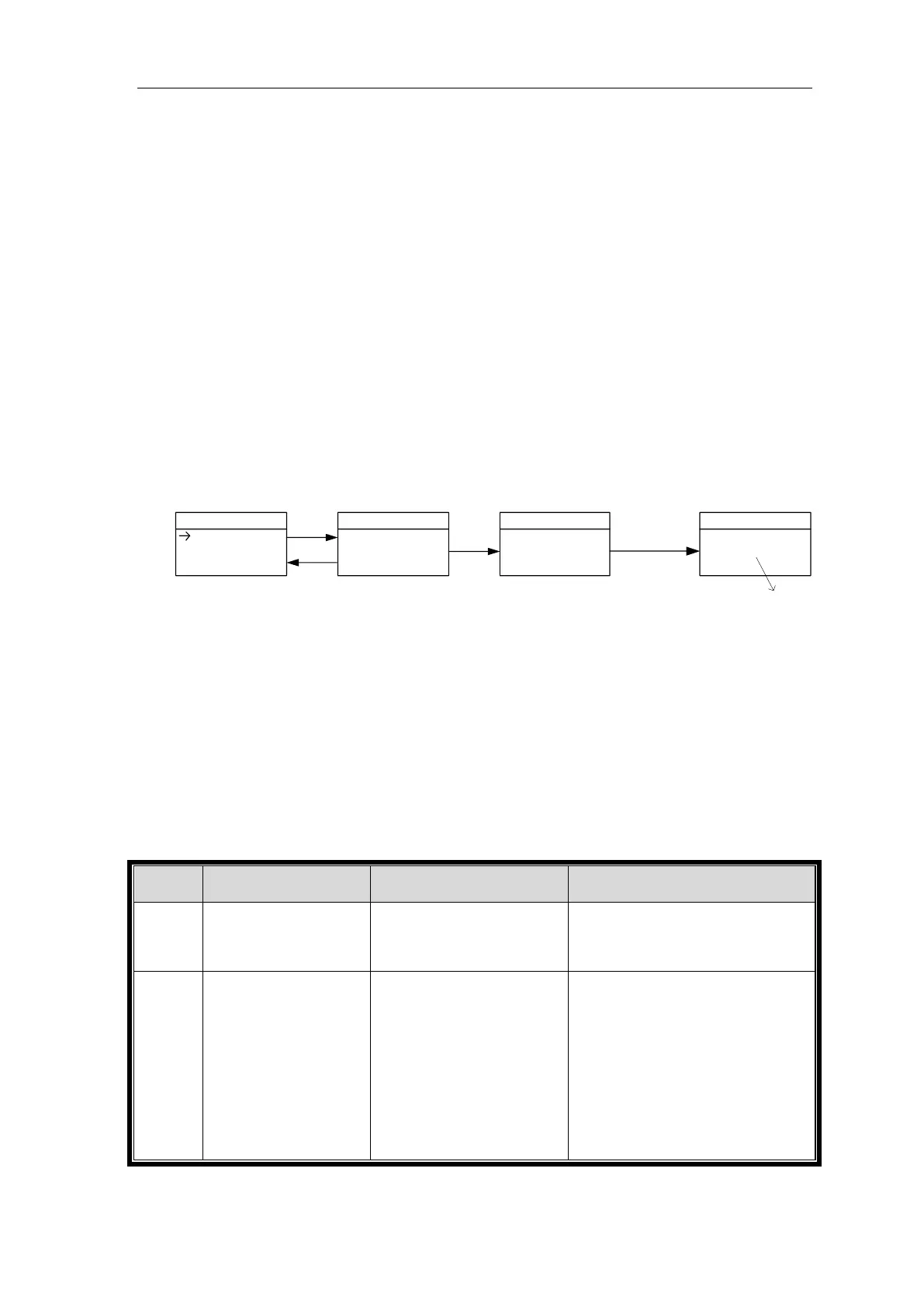

Perform motor initial angle tuning with digital operator based on following procedures shown

below:

Angle Tune ( X0)

Para Tune ( X1)

Angle Tune ( X0 )

Tune start?

[ENTER]to start

Angle Tune ( X0 )

Tune start

Waiting

Angle Tune ( X0)

Tune End

Success

Display:success

or error codes

[ENTER]

[ENTER]

[ESC]

Press Up or

Down button

Motor Tune

FIGURE 5.1 Motor initial tuning with no load (Do not attach steel ropes) sketch

Note: Rotation angle tuning no longer distinguish encoder type.

After pressing “Enter”, tuning starts. First, motor rotates to a firm position, then it rotates

forward(facing to driving shaft, anticlockwise rotation is forward direction)in a constant speed,

rotation speed and time depends on the pole number and initial position, it stops after maximum

one round rotation, then it rotates to one position and remains for 2 seconds again, motor stops and

indicates success. The whole tuning procedure lasts less than 20 seconds.

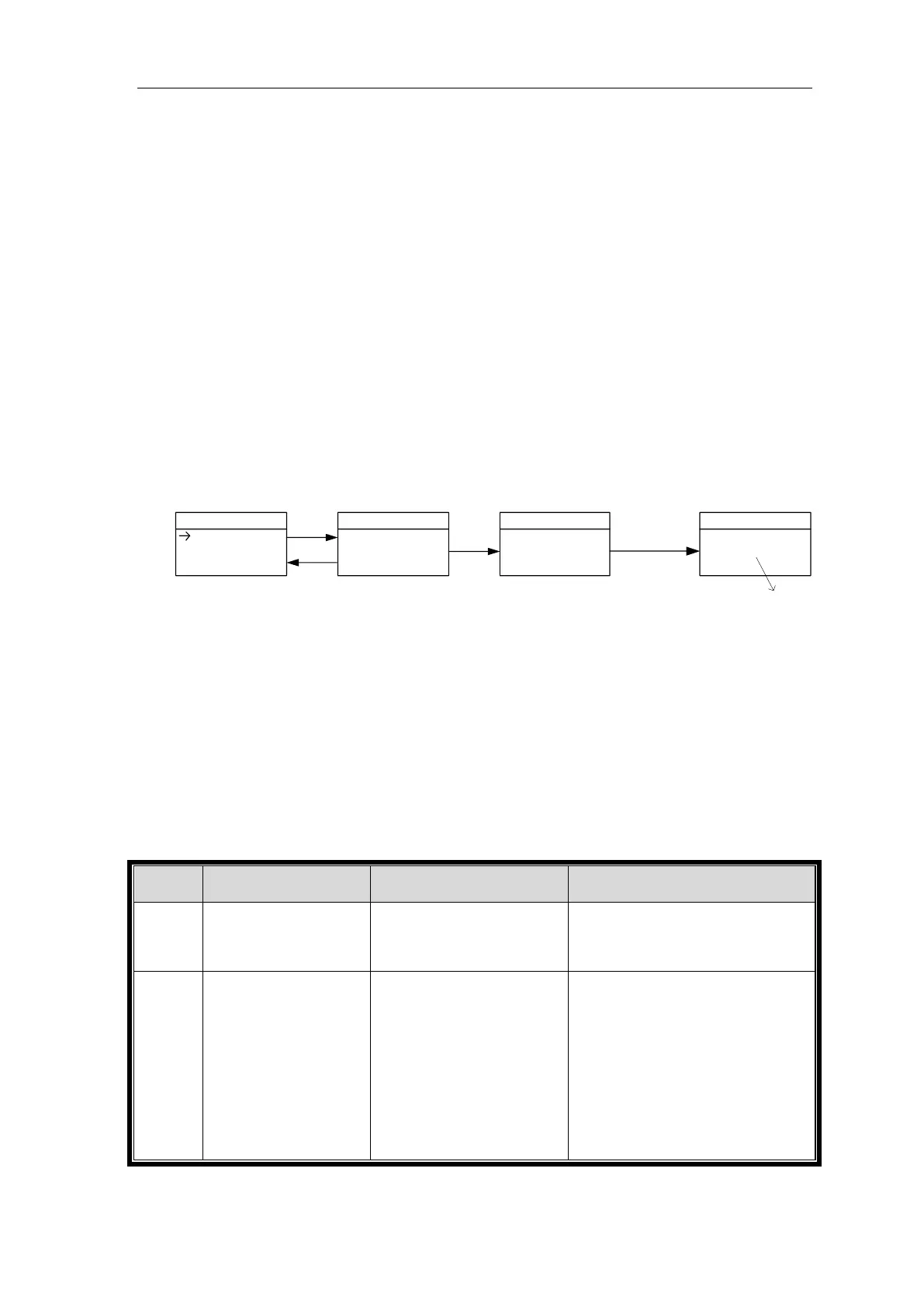

Chart 5.1 Motor Initial Angle Rotation Tuning Fault List

Controller fault

The drive has a failure and

cannot do Initial Angle

Rotation Tuning.

Controller has met fault.

First solve fault according to error code,

then angle tuning again. Refer to Chart

VI Driver Fault List.

Give voltage limit

Already give limit force

during angle tuning, but

feedback current cannot

reach least requirement.

1. Incorrect parameters of

motor or encoder;

2. The difference between

the actual parameters of

the motor and the

estimated parameters of

the driver is too large;

3. Power matching imbalance

between motor and driver

(The motor power is far

less than the drive).

1. Check parameters of motor and

encoder;

2. Decrease F5-08 to complete tuning,

then recover F5-08;

3. Check if the power of inverter is

adapted to motor, refer 2.

Loading...

Loading...