BL6-U Parallel Integrated Controller Quick Commissioning User Manual

15

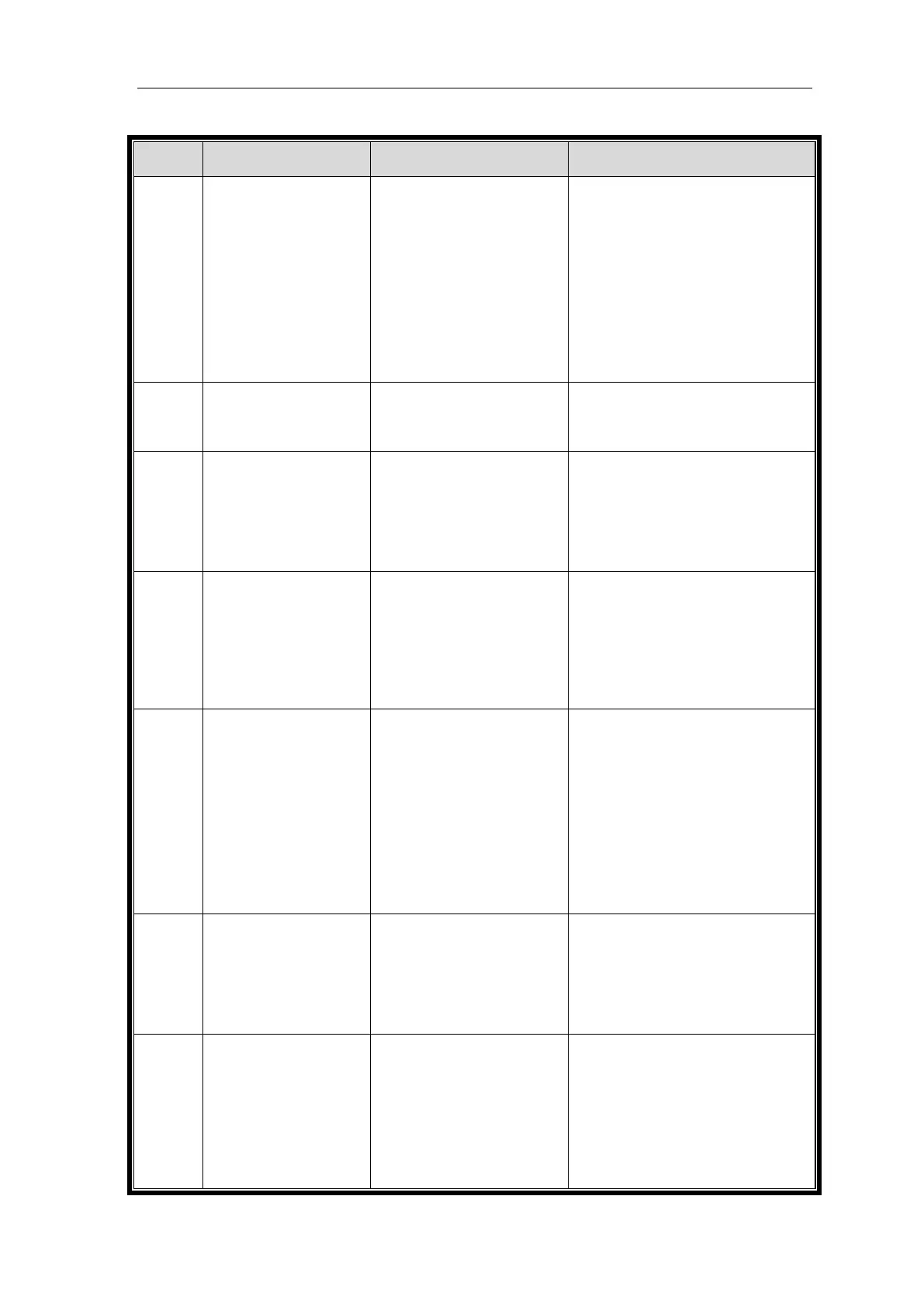

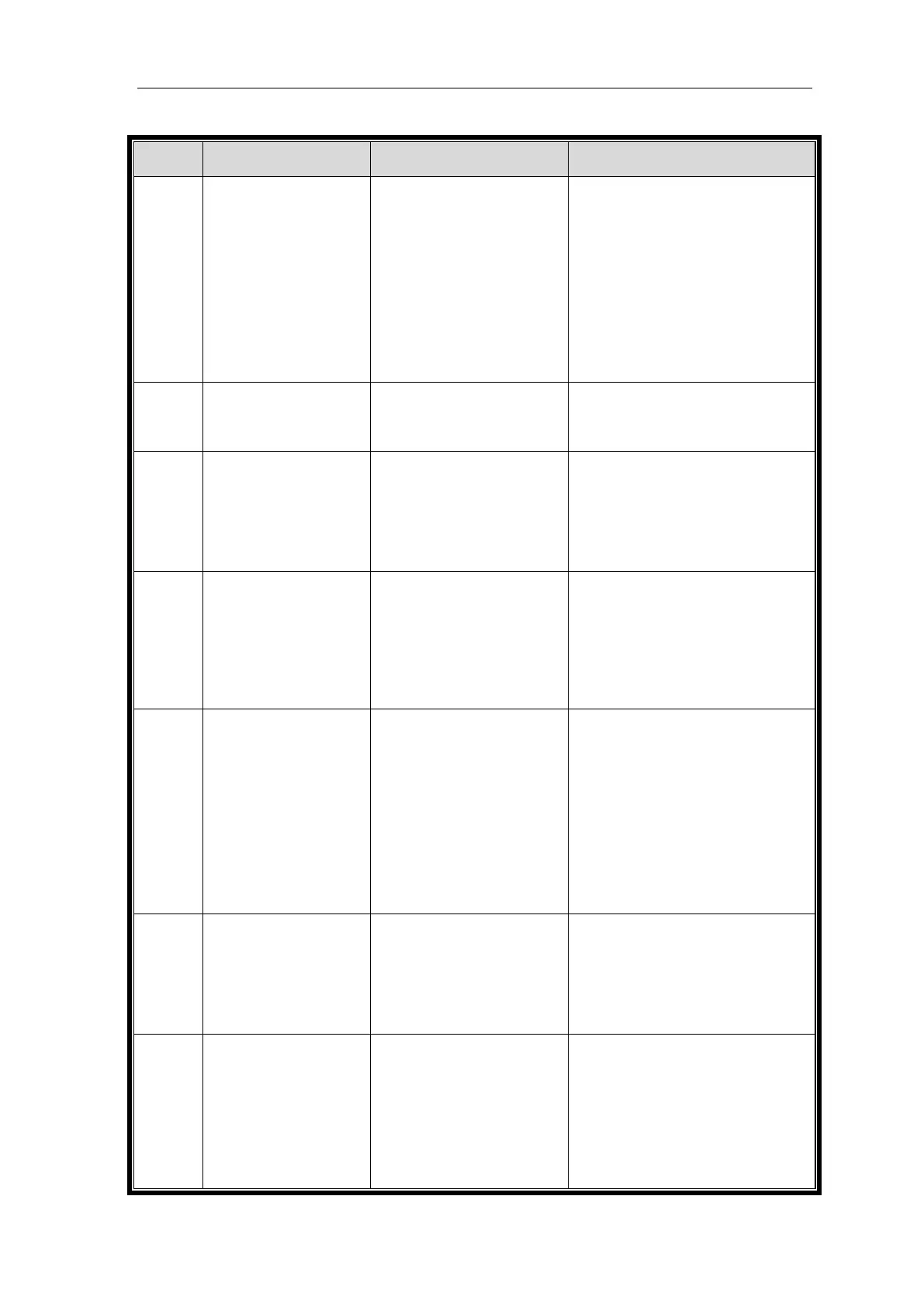

Chart 5.1 Motor Initial Angle Rotation Tuning Fault List (Cont'd)

Output current over limit

During the tuning process,

the driver controller

detects that the output

current has reached the

limit and stops the output,

indicating that the current

is out of limit.

1. Incorrect parameters of

motor or encoder;

2. The difference between

the actual parameters of

the motor and the

estimated parameters of

the driver is too large;

3. Power matching

imbalance between motor

and driver (The motor

power is far more than the

drive).

1. Check parameters of motor and

encoder;

2. Increase F5-08 to complete tuning,

then recover F5-08;

3. Check if the power of inverter is

adapted to motor, refer 2.

ESC input

During the tuning process,

ESC input is effective, and

self-tuning is cancelled.

The hand operator triggers the

ESC button to cancel angle

tuning.

Angle tuning interruption, failure to

complete, please do angle tuning again.

Over time at zero speed

In the process of tuning,

when the rotor is

positioned, the feedback

speed is not zero for a

long time, and it cannot

locate accurately.

1. Motor carrying partial

load;

2. Bad feedback speed of

encoder.

1. Ensure brake is off;

2. Remove interference of encoder.

CD signals of encoder is

abnormal

In the process of tuning, it

is found that CD feedback

position value is

abnormal, and it is

impossible to identify the

CD line sequence.

1. Parameters of motor or

encoder have been

wrongly input;

2. Interference in encoder;

3. Error input of motor or

encoder;

4. Wrong PG type set.

1. Check CD signals wiring;

2. Remove interference;

3. Verify parameters of motor and

encoder;

4. Check PG type set.

Motor does not rotate

In the process of tuning,

the driver cannot control

the normal rotation of the

motor.

1. Encoder connection fault,

no feedback speed;

2. Motor has load or brake

close;

3. The power difference

between the motor and

the driver is too large and

does not match.

1. Check encoder A&B signal

connection, elimination of encoder

signal interference;

2. Make sure motor has no load &

brake open;

3. Check the parameters of the

number of the motor and the

number of the encoder;

4. Detect of power matching of motor

and driver controller, reduce the

rated current [F5-08], and resume

F5-08 after tuning.

Motor rotates in wrong

direction

In the process of tuning,

the direction of the motor

is not consistent with the

control direction, and

there is a reverse rotation.

Motor phase sequences does

not match encoder.

1. Adjust motor phase sequence;

2. Adjust encoder A-, A+ or B-, B+.

Encoder R pulse signal

error

R pulse signal was not

detected for a long time in

the process of tuning.

1. No detection of R pulse

signal;

2. Interference of encoder

signal;

3. Error input of motor or

encoder;

4. In the course of tuning,

the motor is rotated in

distress.

1. Check wiring for R pulse signal;

2. Elimination of encoder signal

interference;

3. Verifying the number of motor

poles and the number of encoder

lines;

4. Open or close the brake in the

process of self-learning.

Loading...

Loading...