BL6-U Parallel Integrated Controller Quick Commissioning User Manual

16

Note:

1. Above description is for SIN/COS encoder;

2. For increment encoder, RF231 correspond to UVW signals, RF234 correspond to Z

pulse. The solution is same, and other faults are same too.

5.2 Motor Initial Angle Tuning with load

For this tuning method, tuning can be carried out with steel rope attached, but please make

sure the following procedures are finished correctly before tuning:

1) Wiring in control cabinet is completely correct, and system under inspection state;

2) Set running parameter(F1), motor parameter(F5), encoder parameter(F8) correctly;

3) All mechanical faults in hoistway are eliminated!

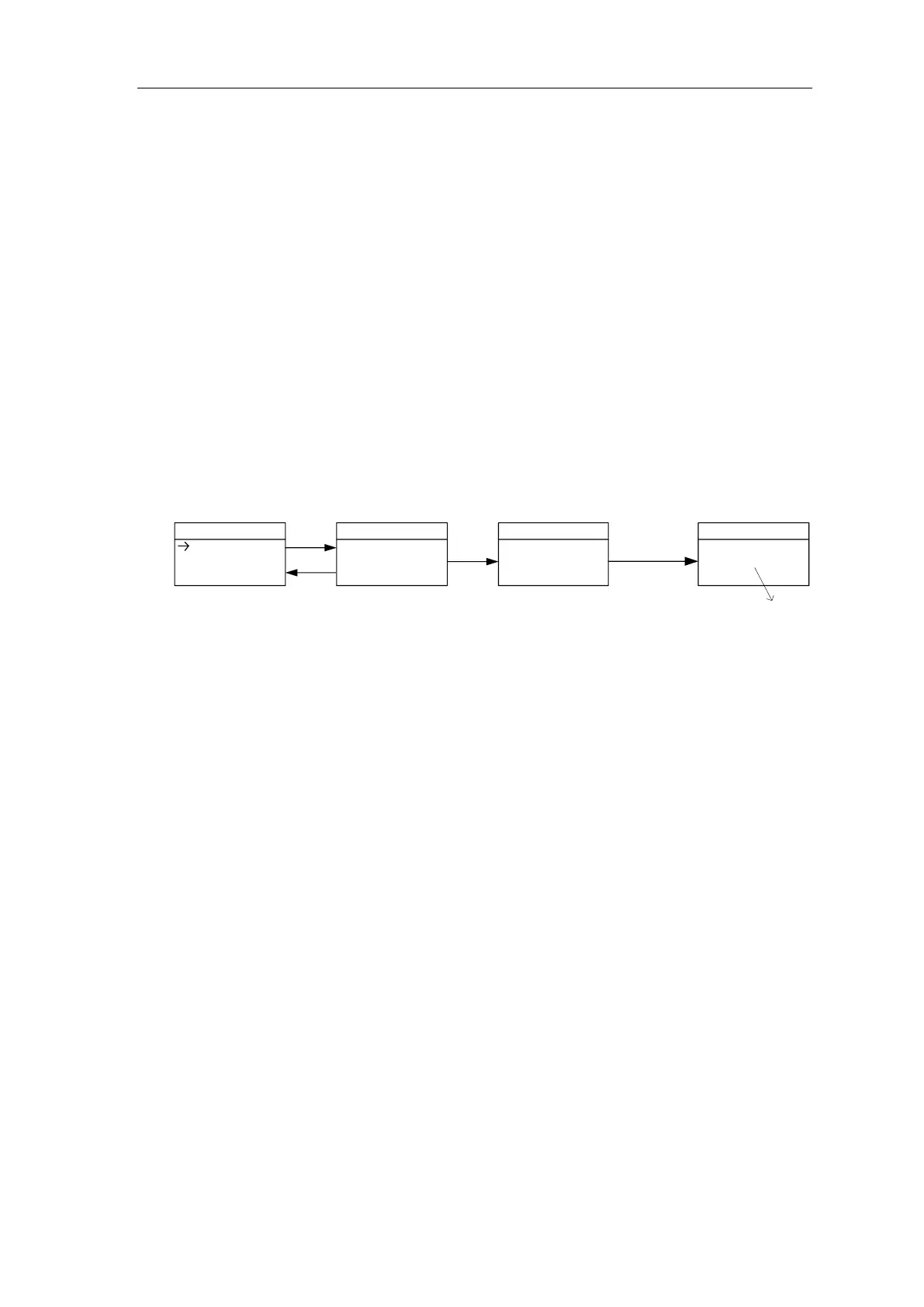

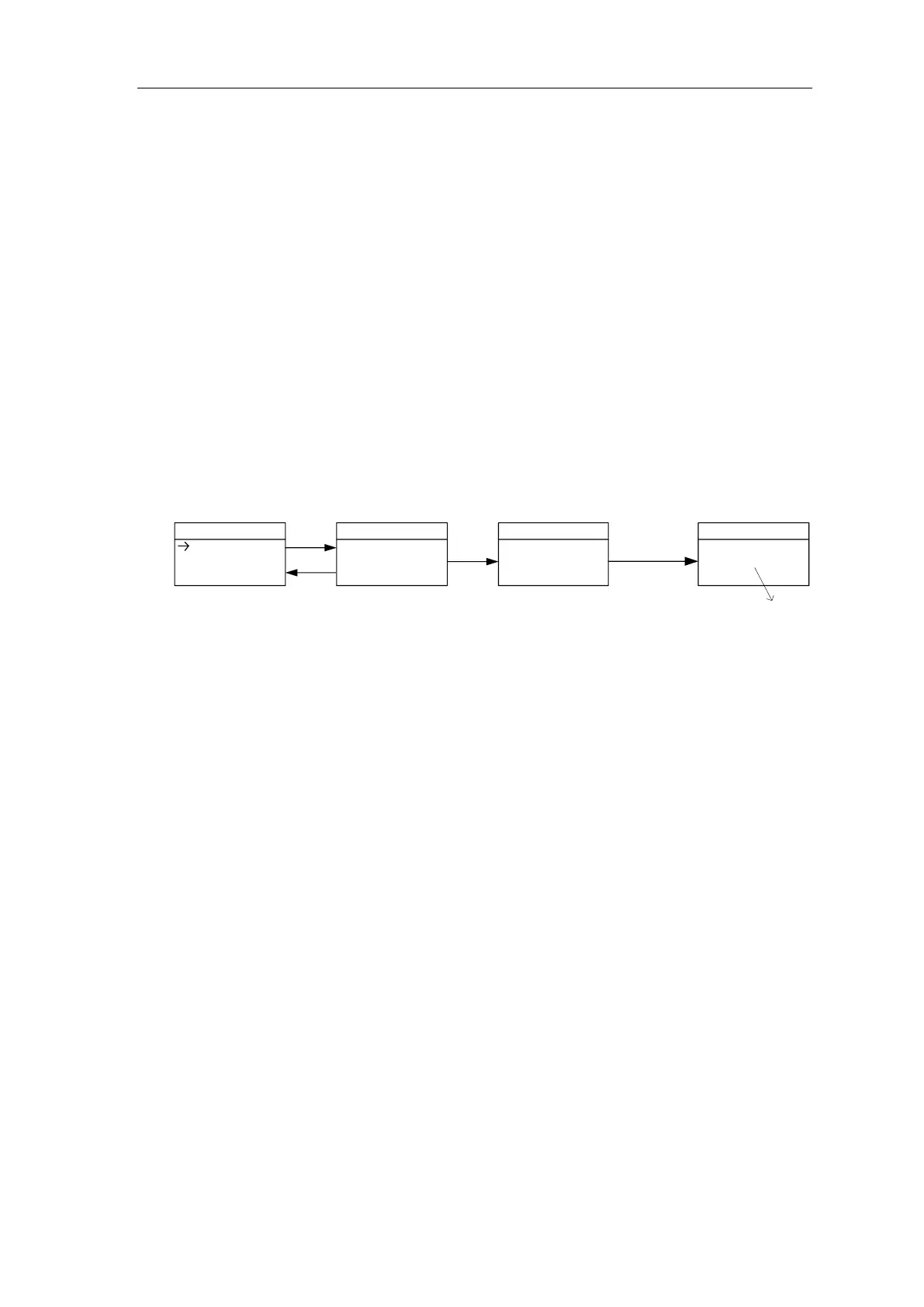

5.2.1 Motor Initial Angle Tuning with Digital Operator

Correctly set PG type F8-02 on digital operator, set tuning method parameter (FC-13) to “1”

(default setting is 1 in BL Series Integrated Controller), perform motor initial angle tuning based on

following procedures shown below:

Angle Tune ( X0)

Para Tune ( X1)

Angle Tune ( X0)

Tune start?

[ENTER]to start

Angle Tune ( X0)

Tune start

Waiting

Angle Tune ( X0)

Tune End

Success

Display:success

or error code

[ENTER]

[ENTER]

[ESC]

Press Up or

Down button

Motor Tune

FIGURE 5.2 Motor initial tuning with load (attach steel ropes) sketch

After pressing “Enter”, tuning starts. When digital operator indicates “waiting” , press jog up or

down button , contactor KDY closes, motor will vibrate a little and give a noise, the duration depends

on motor rated power and rated current, but no longer than 5 seconds, this is static tuning

period.(Motor keep still in this procedure.);(Make sure jog up or down button is pressed constantly,

DO NOT release the button during this period.)Motor will then start and run in inspection speed, jog

up or down, until digital operator indicates success, this is a test running period. Finally, release the

jog up or down button and finish the tuning procedure.

5.2.2 Motor Initial Angle Tuning With digital tubes and operation keys on the upper left of main

board

Prefer to contents of appendix VII.

5.2.3 Please note the following items at Motor initial Angle tuning with load (attach steel ropes):

1) To ensure safety, during tuning process, people are not allowed to stay in car/hoistway.

2) Press jog up or down button can base on the current cabin position;

3) The whole tuning procedures can be divided into two steps: static tuning and motor test run,

make sure there is no gap between two steps. If no fault happens, before digital operator

indicates success, press the jog up or down button constantly (Except fault or error exists!);

4) If car running direction is opposite to inspection run button, correct this through F6-03.0:

traction sheaves counterclockwise rotation & car run down;1: traction sheaves clockwise

rotation & car run up (facing to traction sheaves). Set according to actual situation.

Loading...

Loading...