BL6-U Parallel Integrated Controller Quick Commissioning User Manual

17

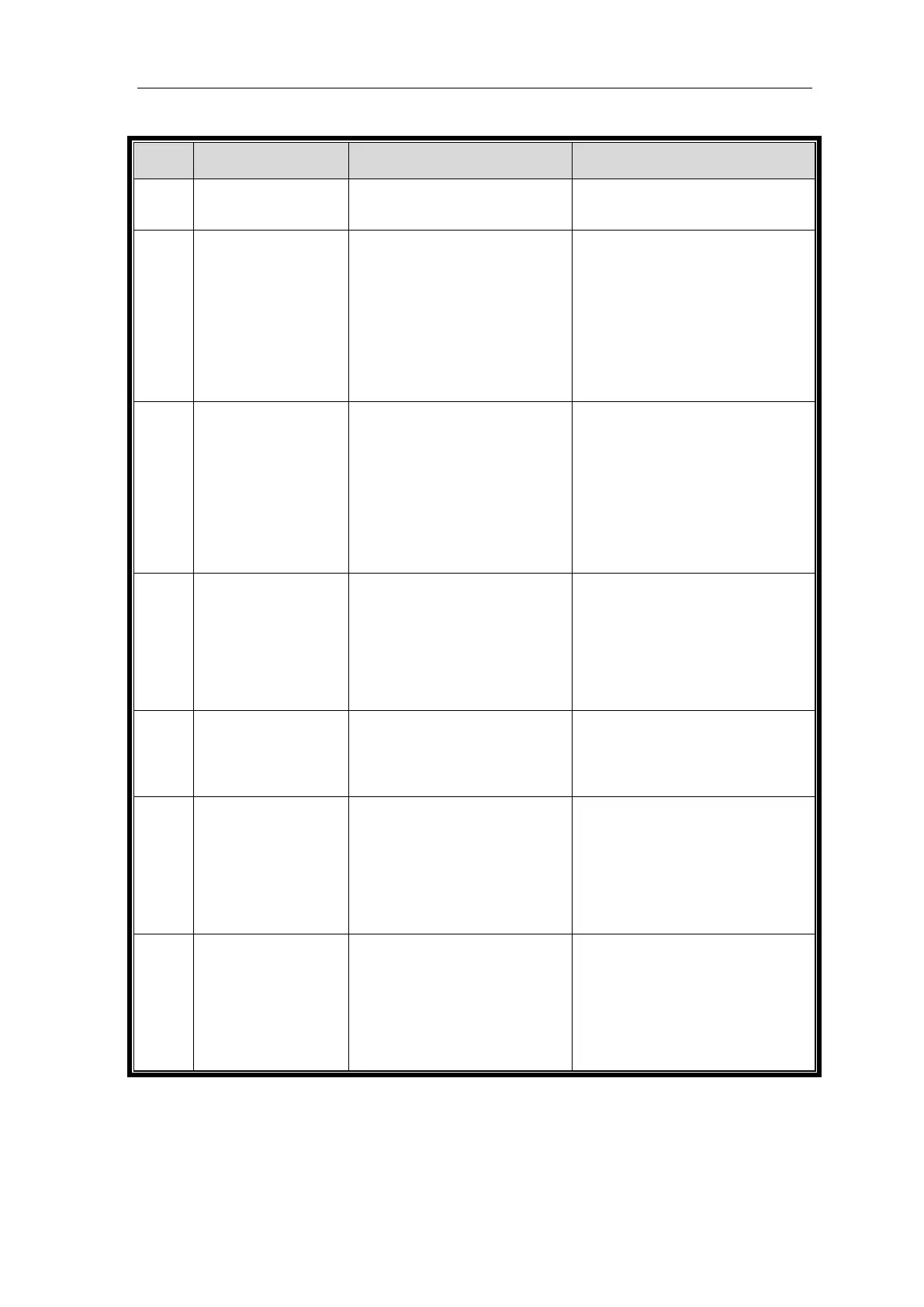

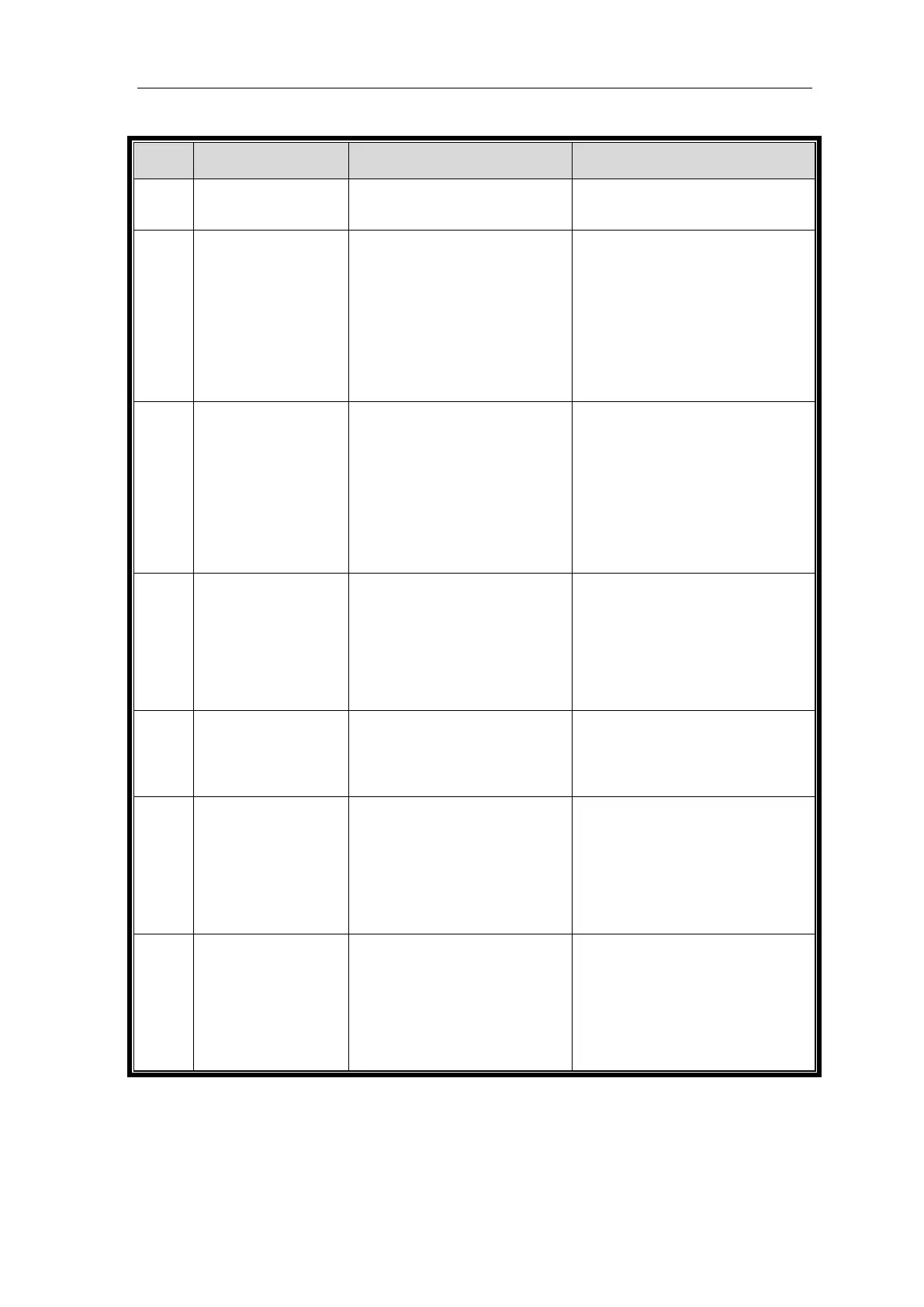

Chart 5.2 Motor initial Angle tuning with load (attach steel ropes) error code

Controller fault

The drive has fault and

cannot do tuning.

First solve fault according to error code,

then angle tuning again. Refer to Chart

VI Driver Fault List.

Give voltage limit

Already give limit force

during angle tuning, but

feedback current

cannot reach least

requirement.

1. Incorrect parameters of motor

or encoder;

2. The difference between the

actual parameters of the motor

and the estimated parameters

of the driver is too large;

3. Power matching imbalance

between motor and driver (The

motor power is far less than

the drive).

1. Check parameters of motor and

encoder;

2. Decrease F5-08 to complete

tuning, then recover F5-08;

3. Check if the power of inverter is

adapted to motor, refer 2.

Output current over

limit

During the tuning

process, the driver

controller detects that

the output current has

reached the limit and

stops the output,

indicating that the

current is out of limit.

1. Incorrect parameters of motor

or encoder;

2. The difference between the

actual parameters of the motor

and the estimated parameters

of the driver is too large;

3. Power matching imbalance

between motor and driver (The

motor power is far more than

the drive).

1. Check parameters of motor and

encoder;

2. Increase F5-08 to complete tuning,

then recover F5-08;

3. Check if the power of inverter is

adapted to motor, refer 2.

ESC input

During the tuning

process, ESC input is

effective, and

self-tuning is cancelled.

1. Release Up or Down button

while tuning;

2. Fault occurs during angle

tuning.

1. Angle tuning interruption, failure

to complete, please do angle

tuning again. Do not forced to run,

there is a danger of losing control.

2. Check whether there is elevator

logic fault, resulting in stop tuning.

Refer to Chart V Elevator System

Faults List.

Over time at zero speed

Over time at zero speed

Before start, feedback

speed is not zero for a

long time

1. Brake open or brake force is

not enough;

2. There’s interference in encoder.

1. Ensure brake is off;

2. Remove interference of encoder.

Current detection error

During the tuning

process, the feedback

current value

ultra-lower limit and

the self-tuning

condition is not

satisfied.

1. Broken circuit at load side or

lack of phase;

2. Imbalance phase of motor side

or rated current wrongly set;

3. Inverter cannot adapt to motor.

(Motor capacity is highly lower

than inverter)

1. Ensure 3-phase connection to

motor;

2. Ensure motor parameters setting;

3. Ensure motor should adapt to

inverter.

CD signals of encoder is

abnormal

In the process of tuning,

it is found that CD

feedback position value

is abnormal, and it is

impossible to identify

the CD line sequence.

1. Parameters of motor or

encoder have been wrongly

input;

2. Interference in encoder;

3. Error input of motor or

encoder;

4. Wrong PG type set.

1. Check CD signals wiring;

2. Remove interference;

3. Verify parameters of motor and

encoder;

4. Check PG type set.

Loading...

Loading...