BL6-U Parallel Integrated Controller Quick Commissioning User Manual

18

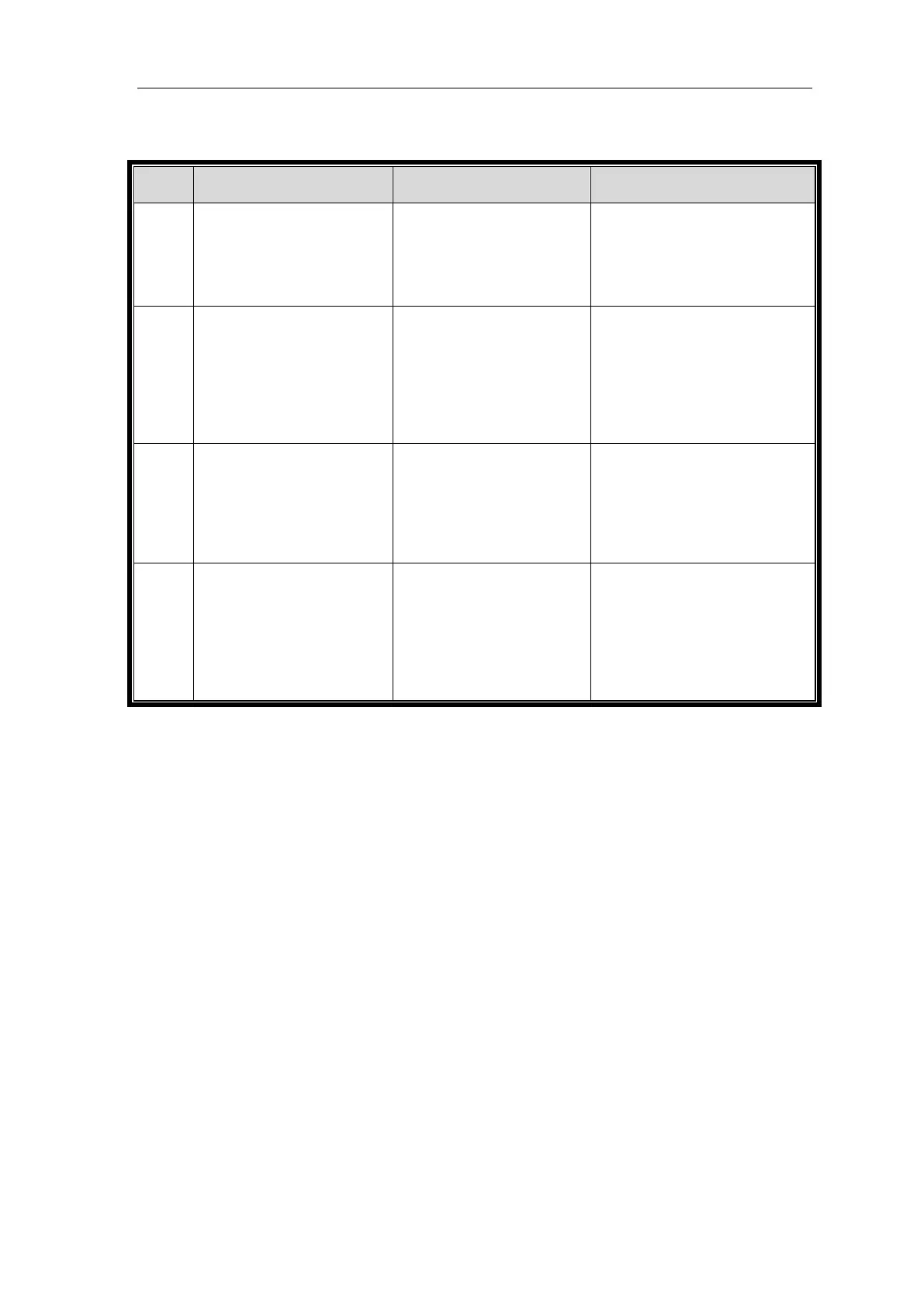

Chart 5.2 Motor initial Angle tuning with load (attach steel ropes) error code (Cont'd)

Motor moved while static

angle calculation

When the motor angle position

is inferred static, the motor

cannot rotate to obtain the

determined current position.

1. Brake open or brake force

is not enough;

2. Bad encoder wire or

interference in encoder.

1. Ensure brake is closed;

2. Check encoder A, B signals,

remove interference

Detection current is too small

In the Initial angle static tuning

process, the output current

value is lower than the lower

limit, and the tuning condition

is not satisfied.

1. The rated current of the

motor may not be in

conformity with the actual

motor;

2. Motor/Controller

connection is incorrect.

(Break circuit or phase

lost)

1. Check motor/controller

connection;

2. Check rated current and rated

power of motor.

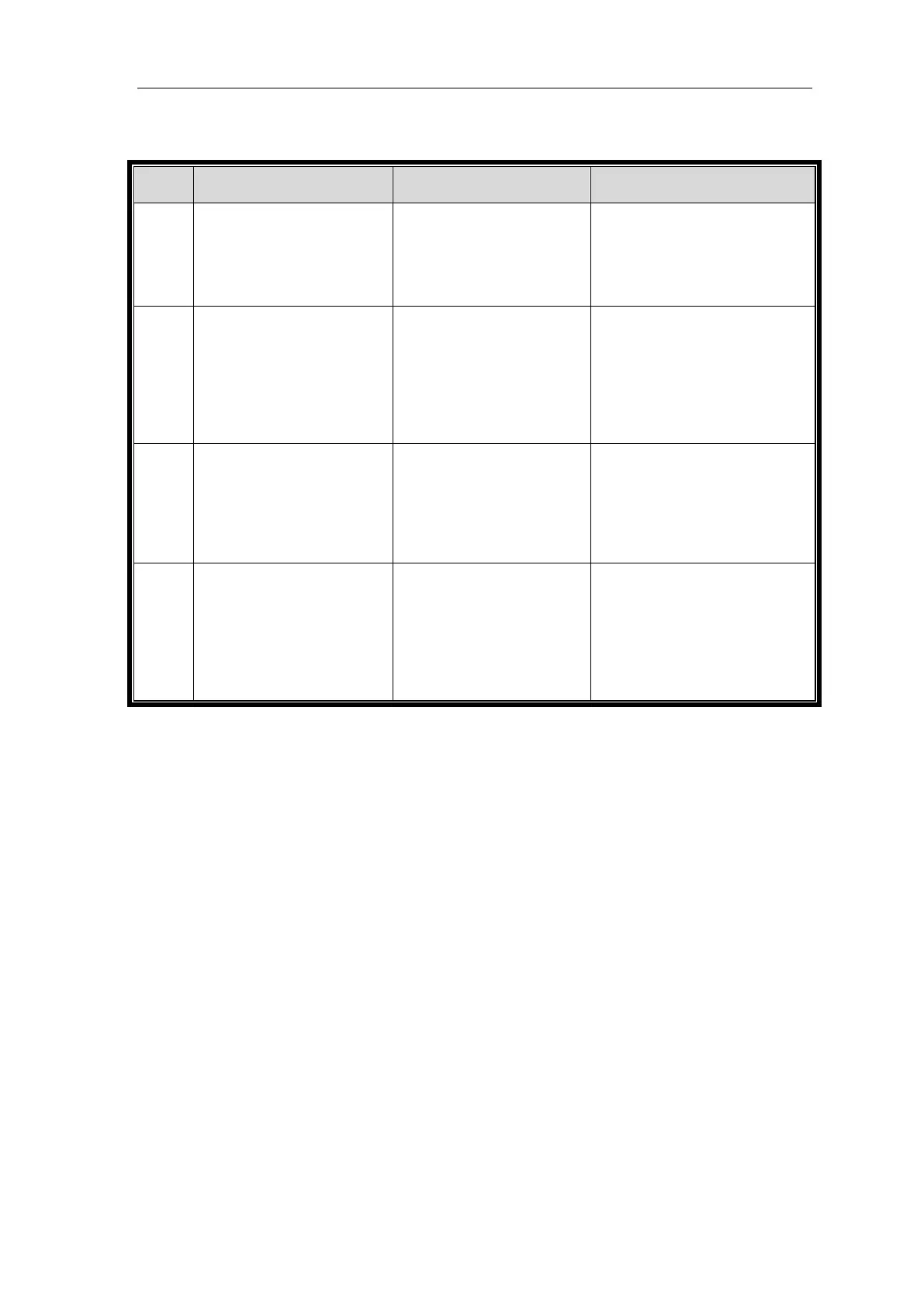

Encoder R pulse signal lost

No encoder R pulse signal

detected after motor tuning for

10s

1. Interference in R pulse

signal;

2. A & B signals connection

error;

3. Inspection elevator speed

setting is too low.

1. Check the encoder wiring;

2. Remove the encoder

interference;

3. Ensure the normal operation of

the motor;

4. Inspection elevator speed

setting is too low.

While static angle tuning,

motor speed is over proof

During static angle tuning, after

initial location, motor need to

rotate for 3 rounds. During

rotating, system give out speed

but receive no feedback and

the lasting time of this status

has been over limit. Then

system announce error.

1. Check if there is feedback from

SIN/COS encoder;

2. Check the phase of power

input.

Note:

1. Above description is for SIN/COS encoder;

2. For increment encoder, RF231 correspond to UVW signals, RF234 and RF239

correspond to Z pulse. The solution is same, and other faults are same too.

Loading...

Loading...