BL6-U Parallel Integrated Controller Quick Commissioning User Manual

19

6 Asynchronous Motor Adjustment

Asynchronous motor does not need angle tuning. But compared with synchronous motor,

NO-Load Current (F5-9) and Rated Slip (F5-10) should be adjusted. The parameters and information

below should be confirmed as well (parameters below are different with synchronous motor).

6.1 Motor Parameters Confirmation

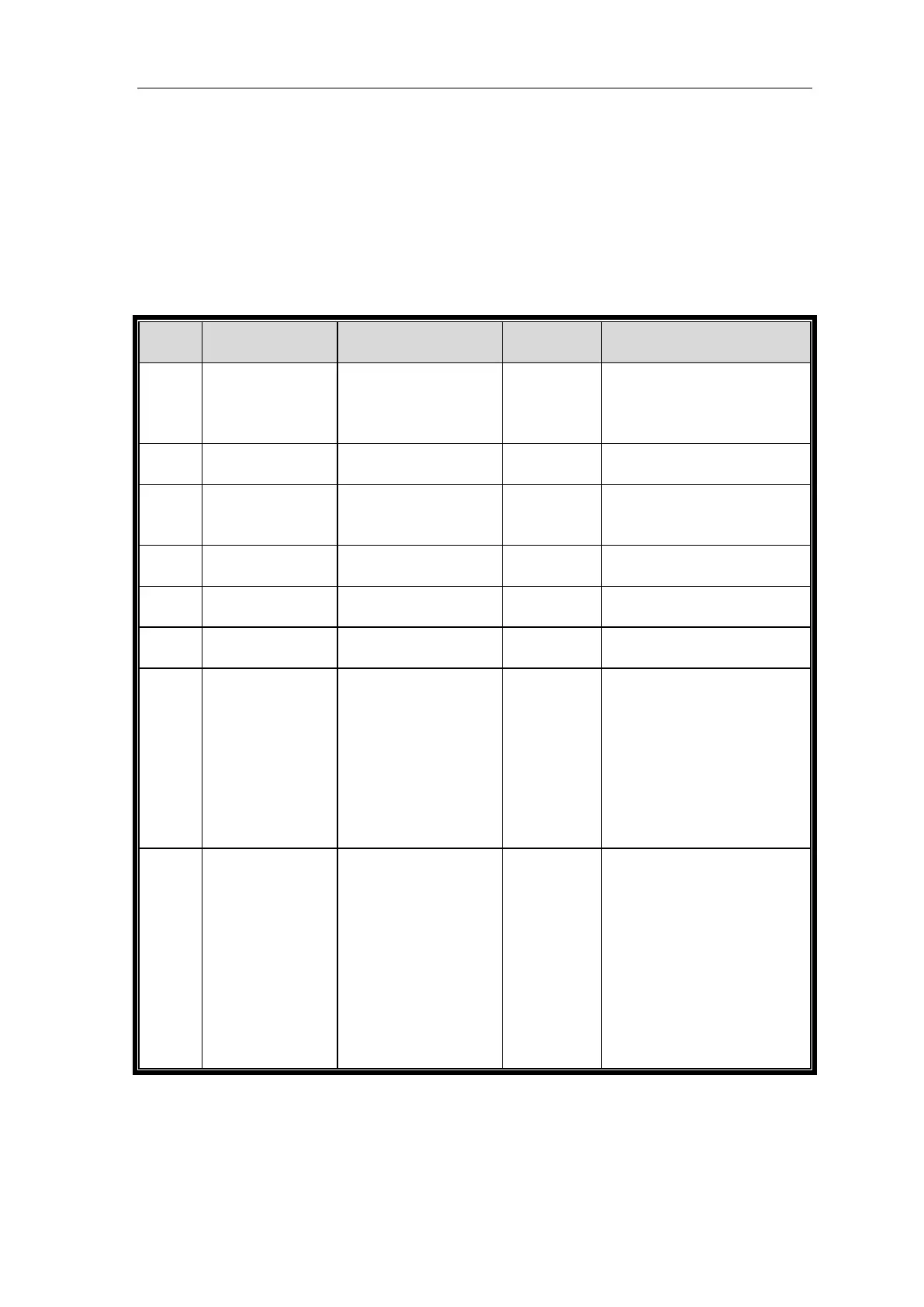

Chart 6.1 Motor Parameters Confirmation

Parameter setting

requirements

Set motor type

0: sync- outer rotor,

1: async machine,

2: sync-inner rotor

Fill in according to actual

motor parameters

Motor synchronous

frequency

(Nameplate)

Fill in according to actual

motor parameters

Motor rated power

(Nameplate)

Fill in according to actual

motor parameters

Motor rated speed

(Nameplate)

Fill in according to actual

motor parameters

Motor rated current.

(Nameplate)

Fill in according to actual

motor parameters

For asynchronous

machine, no-load

excitation current.

Fill in according to 30% rated

current, adjustable in 20% to

40%;

If rated current is set too

small, motor will run with

howling sound; If set too

large, fluctuation feeling will

be obvious in steady speed

period.

For asynchronous

machine rated slip.

(Nameplate)

Rated Slip=rated freq-(Rated

Speed× pole pairs/60)

If rated Slip is set too small,

motor speed could not keep

pace during acceleration--OE

fault.

If set too large, motor could

not keep pace with

acceleration Ref in steady

period or indicate

overcurrent fault.

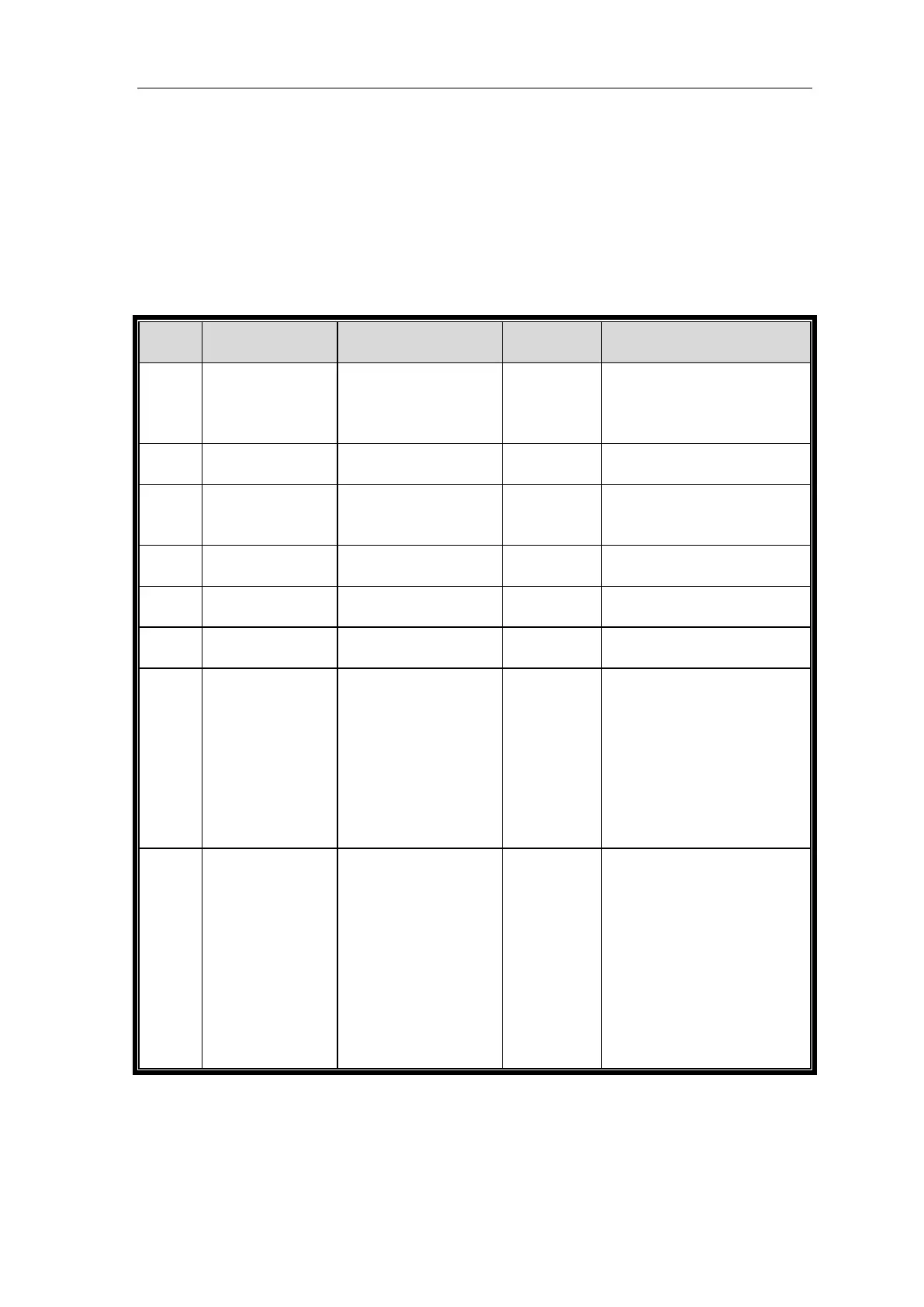

6.2 Encoder Parameters Confirmation

Loading...

Loading...