BOGE Operating instructions for C 10 L...C 20 L series screw compressors Page 39

Maintenance 5.3 Regular maintenance work

– Close ball valve at the compressed air outlet.

– Vent the compressor (as described in the beginning of the chapter).

– Wait approx. 3 minutes to permit the oil to settle.

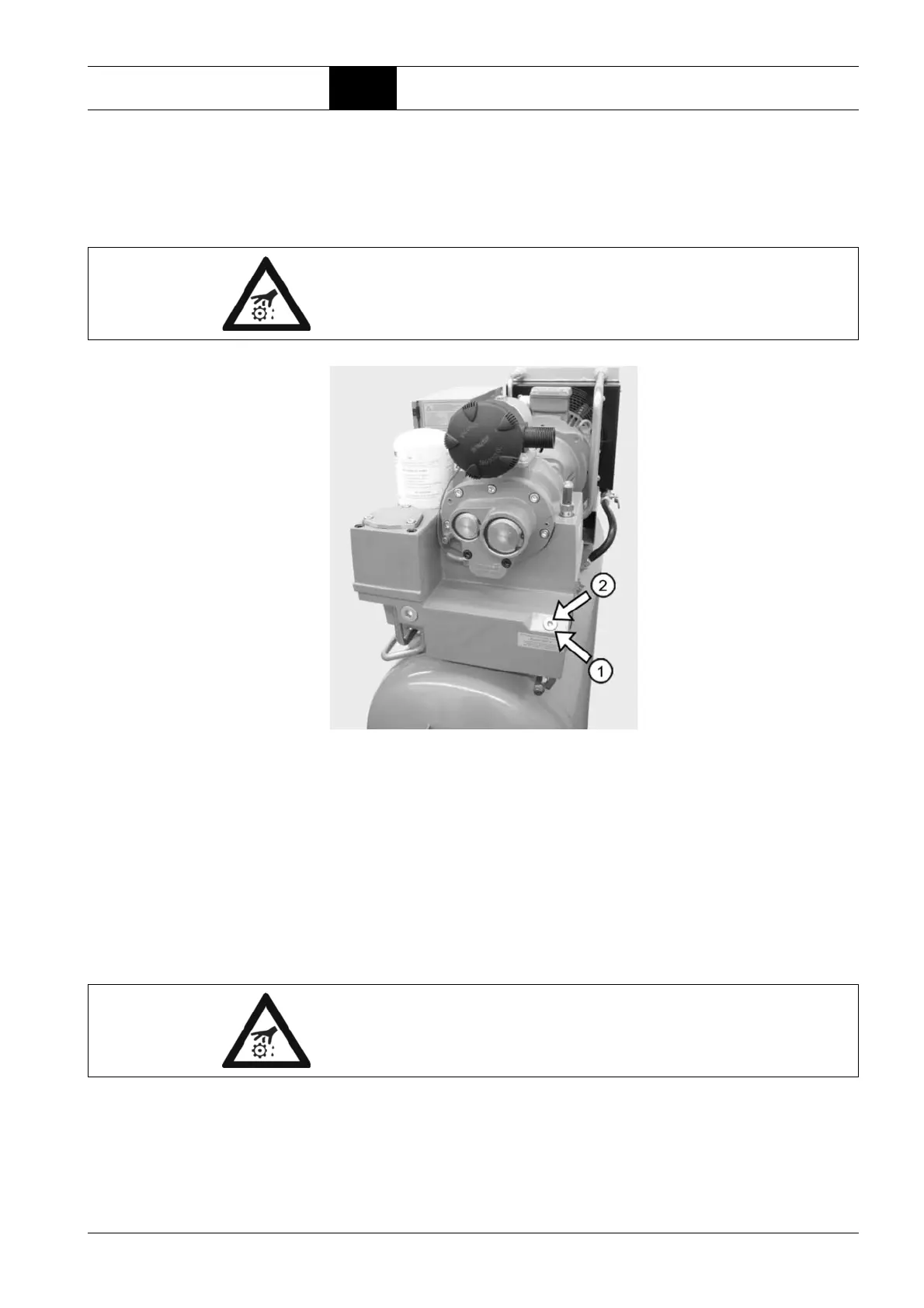

Fig. 5.3: Checking the oil level, topping up with oil

Changing the oil filter

Change:

– If mineral or food-suited oils are to be used,

please be advised that the oil filter must be replaced after the first 500

operating hours.

– After 3,000 operating hours, however, no later than after one year.

– With each oil change!

– Switch off the compressor using the OFF button.

Caution: Risk of injury!

Danger of burning due to hot oil!

Always wear safety gloves!

– Remove plug (2) of oil fill-

ing socket(1).

– Check oil level.

The oil level must not

drop to a level more than

0.8 inch below the bottom

edge of the thread.

– If necessary, top up with

oil to the lower edge of the

thread ("max." mark) on

the oil filling socket.

– Screw plug (2) back in.

– Open ball valve at the

compressed air outlet.

Caution: Risk of injury!

Press Emergency Stop button, open mains disconnection device and secure

against unintentional switch on by means of a padlock.

Loading...

Loading...