11

3. Preparation & adjustment

3.1 Assembly

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from

power source before installing and removing accessories, before adjusting or

changing set- ups or when making repairs. Be sure all switches are in the OFF

position. An accidental start-up can cause injury.

FITTING THE FEED HANDLES

1. Fit each of the three feed handles by screwing them into the hub in clockwise

directions;

2. Tighten firmly by hand.

The handles are supposed to face slightly outward. Be careful not to cross-thread any of the

components.

MOUNTING THE DRILL GUARD

The guard protecting against chippings and accidental contact must always be mounted

during operation.

1. Hold the guard in front of the magnet, aligning the slots in the guard with the holes in

the magnet;

2. Fit the screws into the hole located in the side of the magnet.

WARNING: Always use the safety guard.

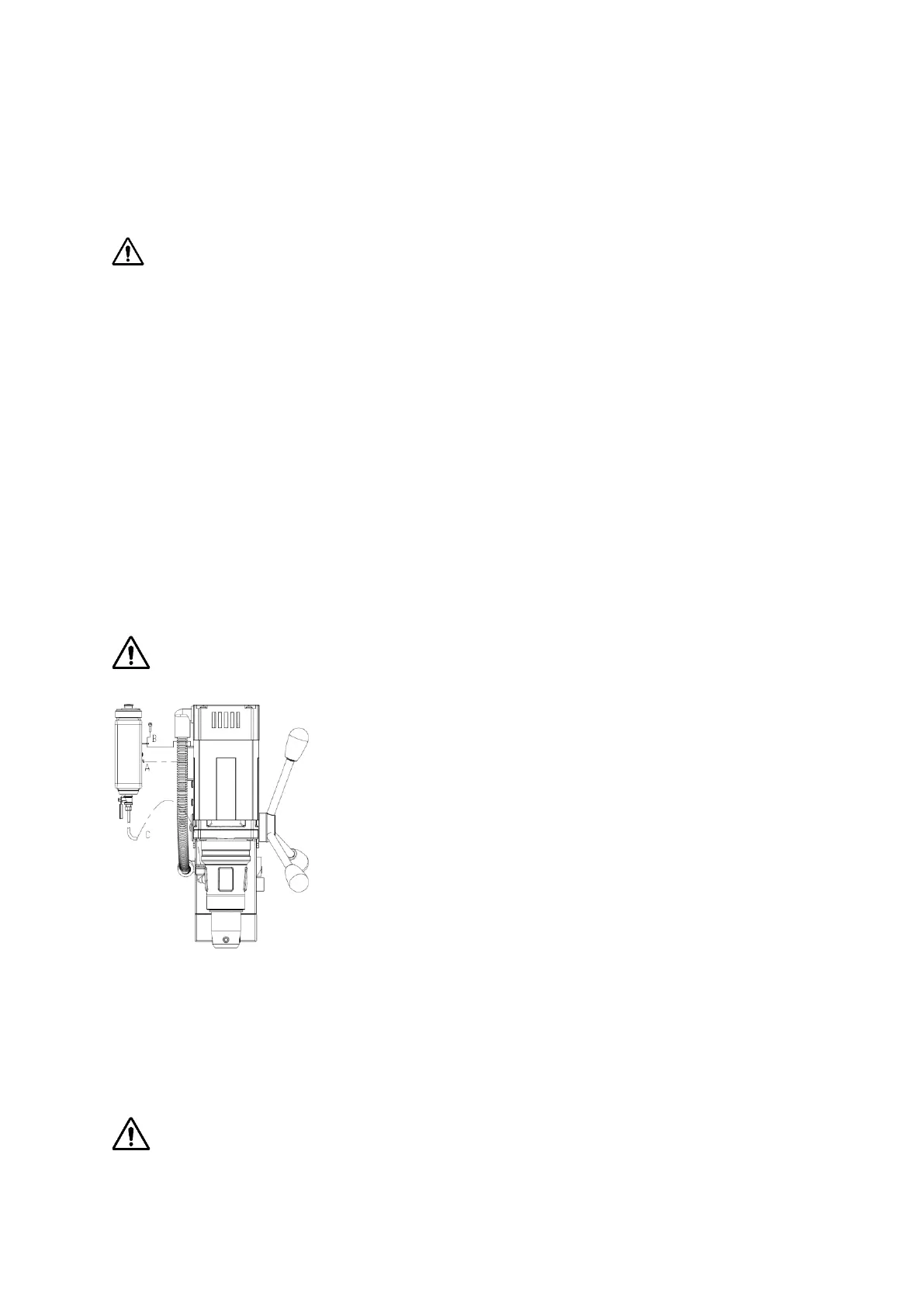

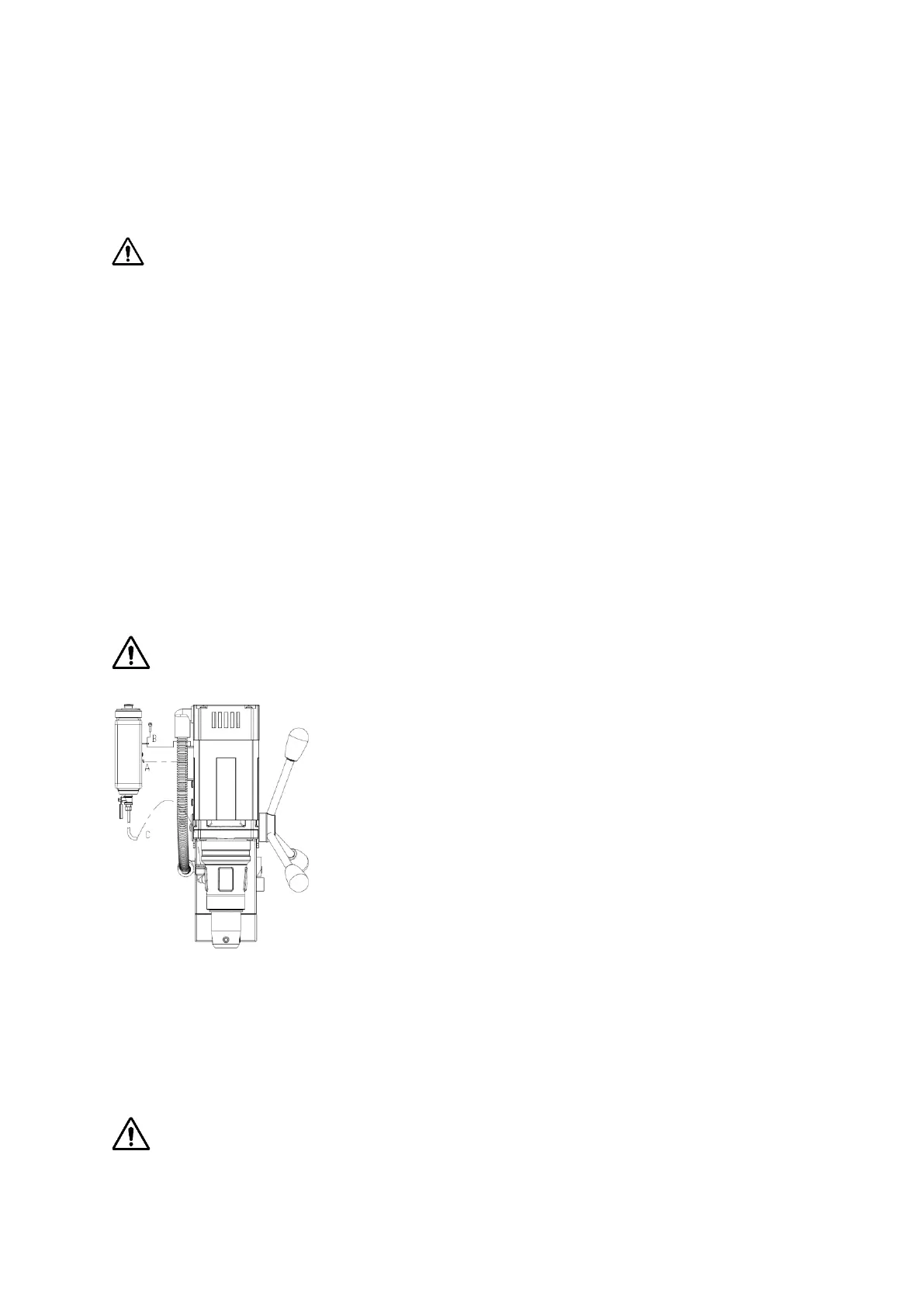

FITTING THE LUBRICATION SYSTEM

The lubrication system can be used for horizontal drilling

applications (the drill being used vertically).

1. Hang the tank (A) on the tank holder

2. Position and tighten the attachment pin (B)

3. Connect the hose (C) to the fitting on the gearbox. Make

sure the hose is connected fully and tightly.

4. To disconnect the hose, press the blue ring on the

connection and gently pull out the hose

[image 3-1]

FITTING THE SAFETY CHAIN

1. Wrap the chain around the work piece and machine frame handle

2. Ensure the chain is taut

3. Securely close the chain using the lock

WARNING: Always use the safety chain when using machine vertically. For safety

reasons we advise against using the machine upside-down in overhead applications

Loading...

Loading...