14

4.2 Electromagnet

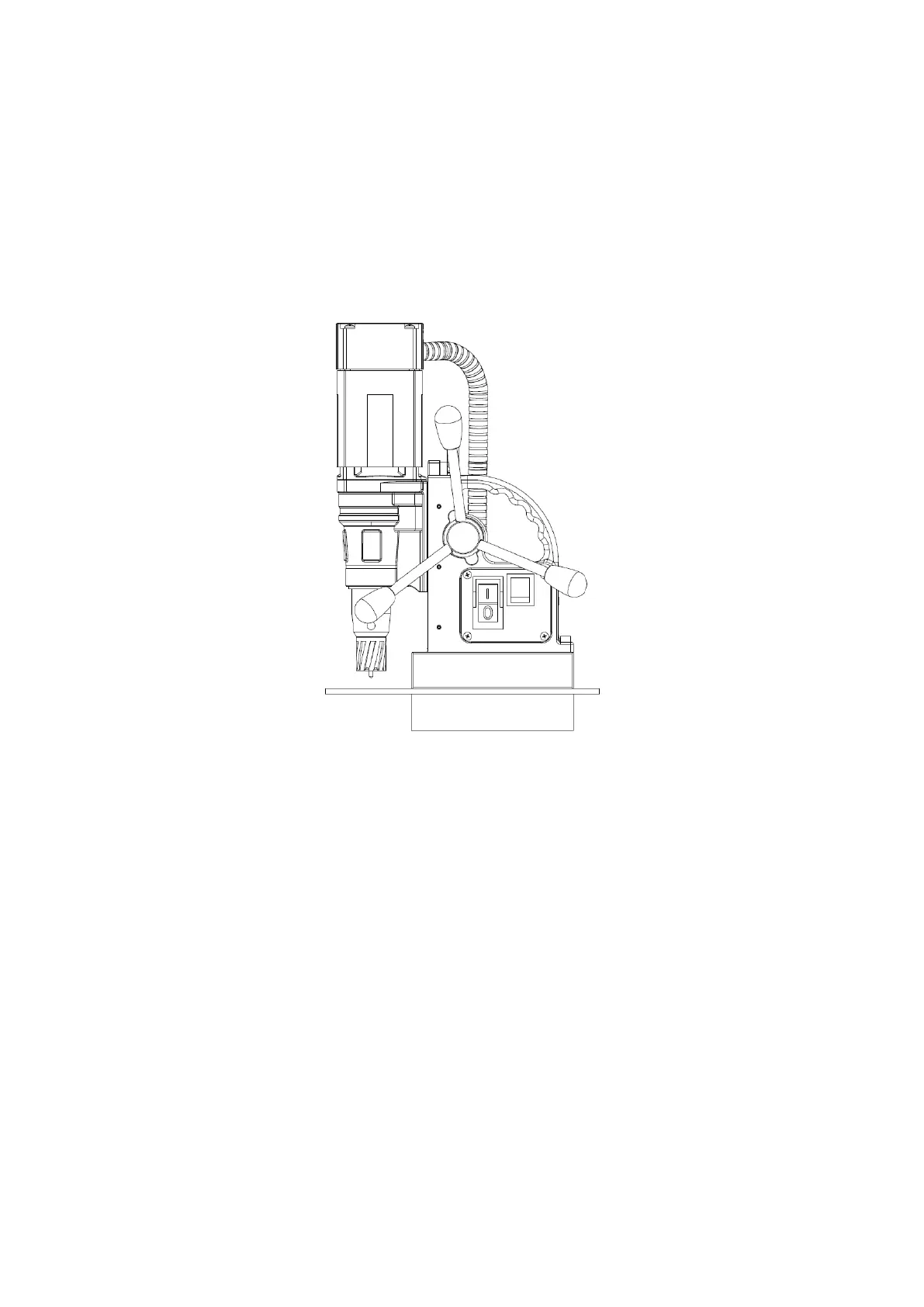

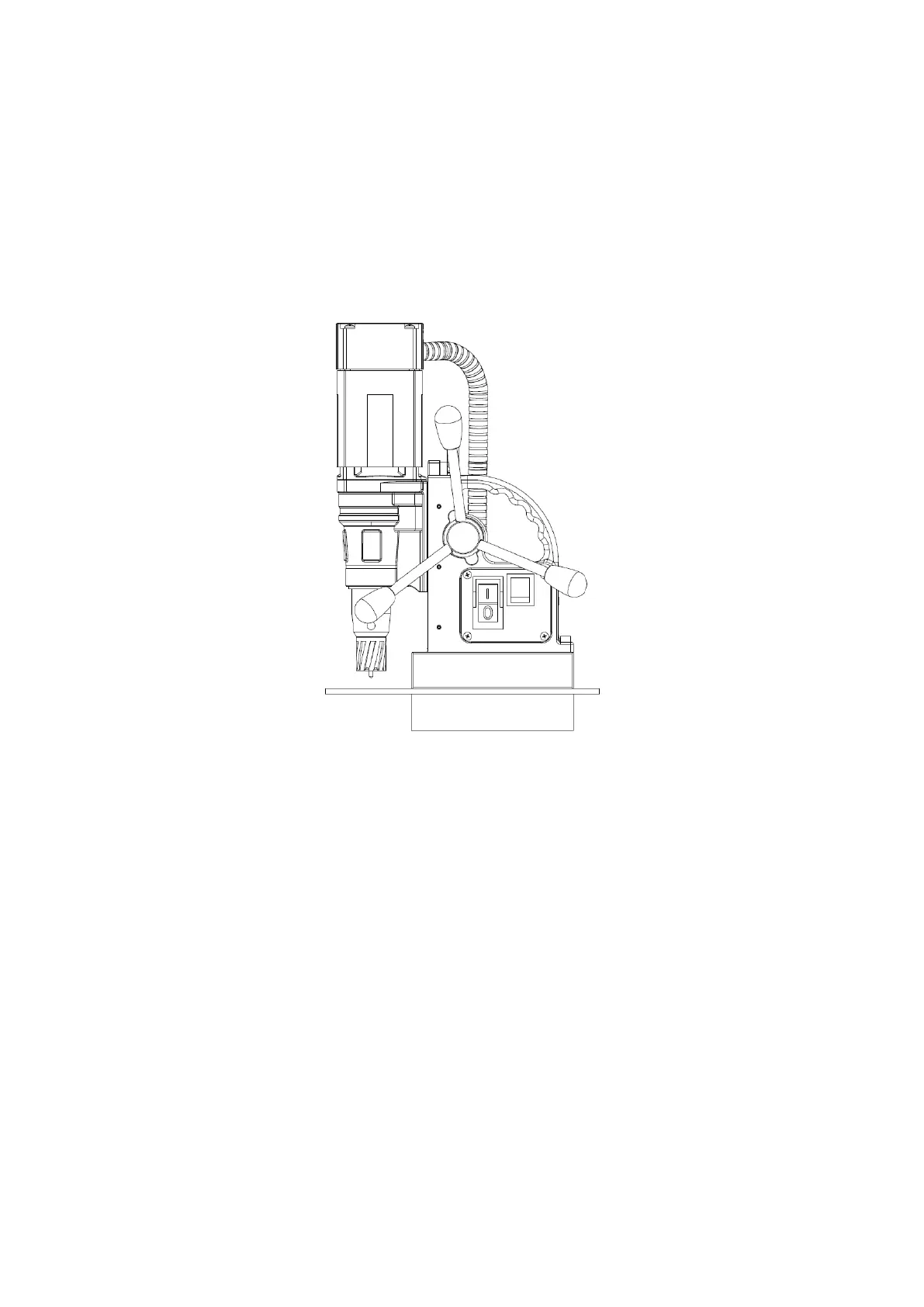

Make sure the magnetic drilling machine is placed on a smooth, clean, level and solid

surface without any objects or debris in between to guarantee maximum adhesion.

The workpiece must be at least 6 mm (1/4") thick for the magnet to stick, but minimal 3 mm

(1/8") thick to hold the weight of the machine and to drill safely. In case the workpiece is

between 3 mm (1/8") and 6 mm (1/4"), make sure to make a proper base to create a good

magnetic field as shown below.

[image 4-2]

The electromagnet will work best on surfaces of at least 10 mm (3/8") thickness.

The electromagnet may not be able to create a good enough magnetic field. Causes may be:

- Surface not flat

- Workpiece not magnetisable (e.g. aluminium or stainless steel)

- Workpiece coated or painted

- Workpiece not thick enough

Make sure to solve any of these matters before proceeding in any way and creating unsafe

situations.

1. Connect the machine to the mains/work piece;

2. To activate the magnet, press the red magnet switch. It will be lit;

3. To deactivate the magnet, press the same switch again.

It is not a certainly that the magnet will not release from the material. We accept no

liability in case the magnet does not function or functions poorly.

Loading...

Loading...