11

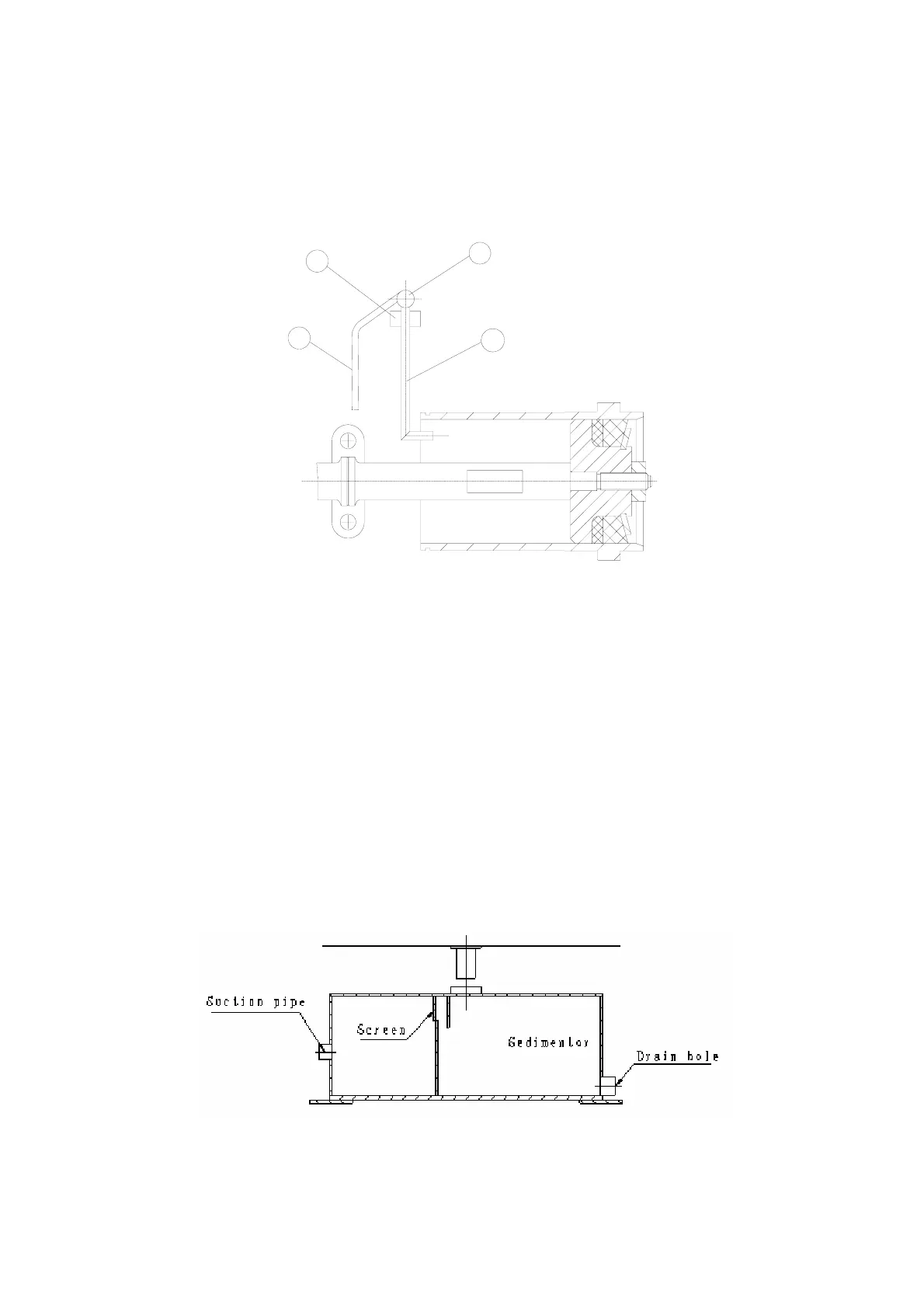

Stationary spray pipes have been used on F-series pumps Ref. Fig 5. It consists of a fixture frame (1), steel

pipe (2) and spray nozzle (3), it makes cooling fluid spray to piston and liner. Adjust cooling water supply

to the manifold and inspect spray nozzle operation very often to make sure the nozzle is pointed directly at

the piston.

Fig. 5

(1) Fixing frame (2) Steel pipe (3) Spray Nozzle (4) Soft pipe

Cooling fluid is transfused from spray pump (No.3 in Fig .7) through Water tank (No.5. in Fig. 7) to the

manifold on left/right wall plate of the frame. Adjust regulating valve (No.4 in Fig .7) to supply as

much water as possible to the liners without splashing back on the crosshead extension rods. Avoid

some water will work back into the power end to contaminate the lubrication oil.

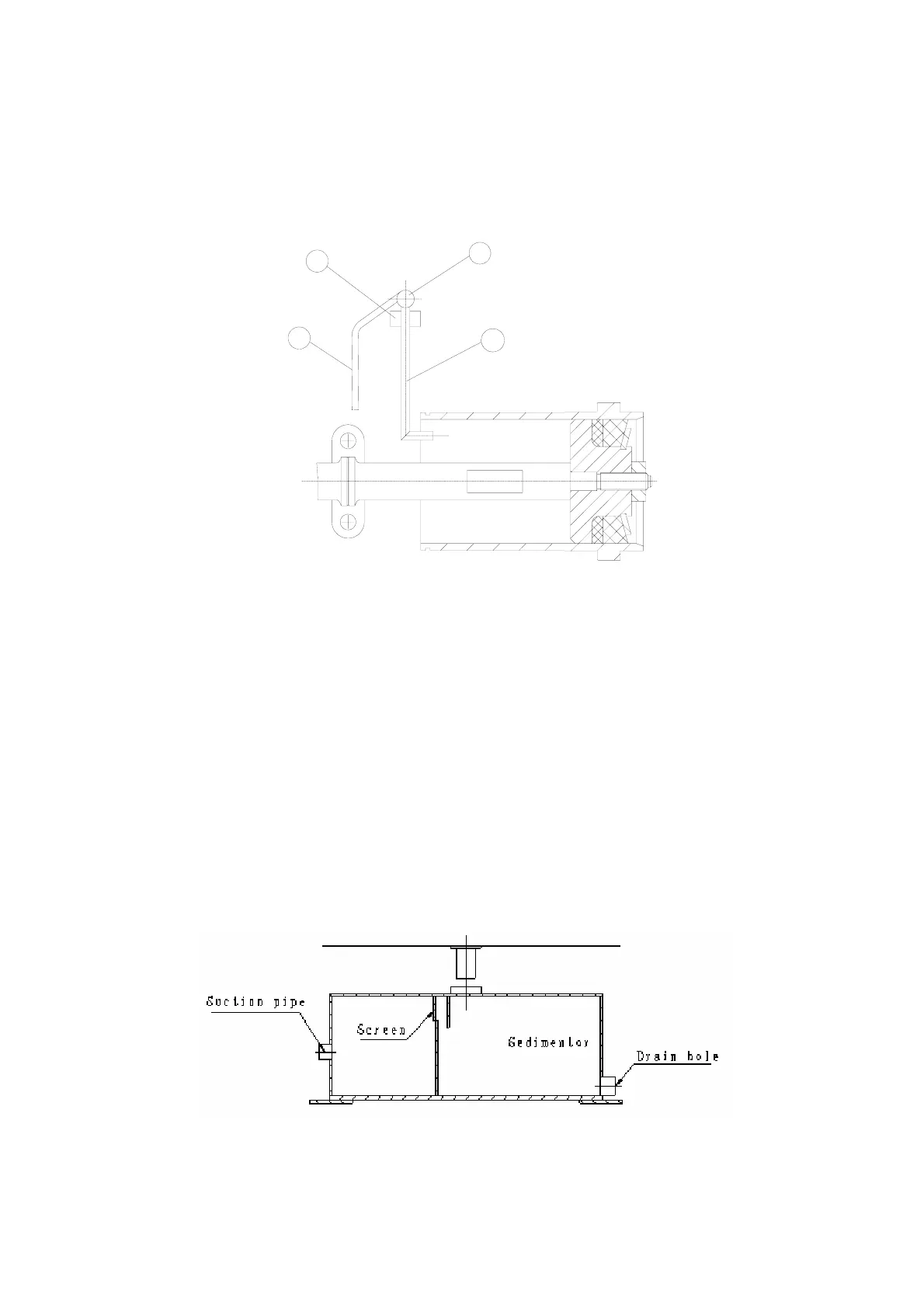

The cooling fluid returns to the setting chamber from the crosshead extension rod compartment, and

as the fluid overflows through the filter screen between the two sections of the tank, the solids are

allowed to settle out. The filter screen will catch much of the foreign material in the fluid. Refer to

Fig .6.

Check cleanliness of the cooling fluid at frequent intervals and CLEAN and FLUSH reservoir and

replace the cooling fluid as required. Increasing sand grain in contaminated fluid will cause premature

abrasion of liner and piston or stoppage of the spray nozzle or spray tube.

Fig. 6

2

1

4

3

Loading...

Loading...