Instruction Manual for F1300/1600 Mud Pump

37

5) Check the bottom plug (Item2) situation, and assure every edge is smooth. Putting the new one

vertically when change the pierced or worn-out bladder; the shrink range is 0.076~0.152mm(0.003~

0.006").

6) Assembly new bladder.

Compressing it flat and rolling up like a screw, and then put it into through the top hole. Release and

adjust in order to match with the shell; Seat neck seal of bladder on shell port; meantime coat grease

on neck inside.

7) Assembly the cover (Item 5).

8) Tighten nuts (Item R2) with the torque 1625-2170N.m (1200-1600ft.lbs).

9) Charge following Item1.7.2.

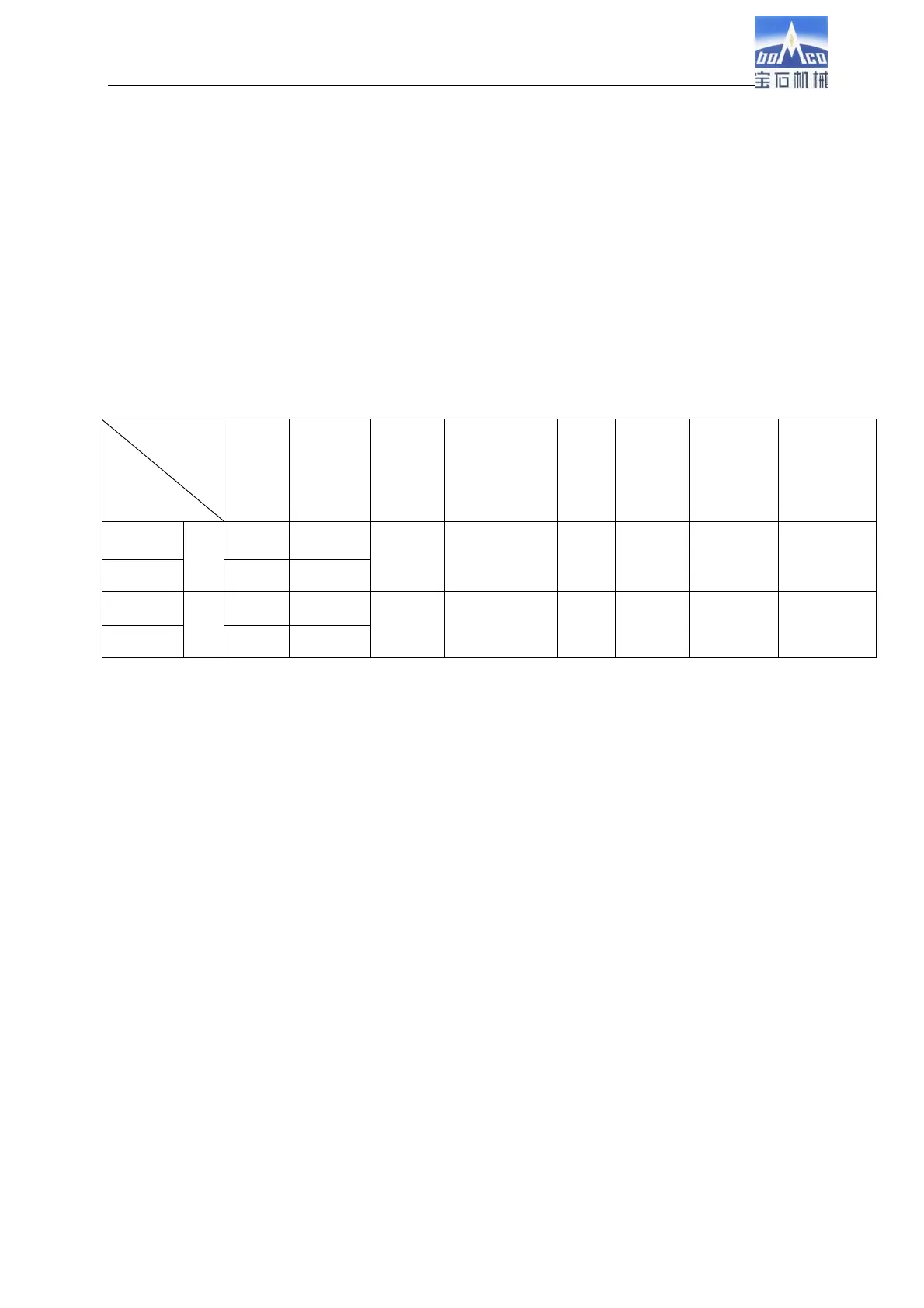

3.13 Approximate Weights of F-1300/1600 Pump Assemblies

Note: each pump includes three fluid cylinders and 1/3 fluid end is any one of them.

4. Maintenance of Pump

Proper maintenance of the pump in time is the necessary measure to assure the pump working and

prolong the service life. For using any pump, maintenance should be paid more attention to.

4.1 Daily Maintenance

1) After stopping the pump, check the oil level of power end, at least once a day. If chain drive is

used, the oil level of chain box should be checked.

2) Check the change of lubricating oil pump. If the pressure is very low ( less than 0.035MPa) or zero,

check if there is any block in suction manifold and discharge filter in time.

3) Check that suction dampener works normally.

4) Check if the pressure of discharge pulsation dampener meets the requirements.

5) Check the reliability of relief valves, if necessary, they should be changed.

6) Check the working situation of liner and piston, it’s normal that a little mud is taken out with piston.

If there is leakage, the piston should be changed. Check the abrasion of liner inner bore, if the

abrasion is severe, the liner should be changed in time.

7) Check the front compartment of the frame, clean thoroughly if there is a lot of mud, oil dirt setting.

8) Check water tank of spray pump; clean the tank, refill water in time, change water contaminated.

NAME

UNIT

Pinion

shaft

assy.

Crank

shaft

assy.

Cross-

head

Crosshead

pin and guide

Rear

cover

Suction

pipe

Discharge

pipe

1/3 Fluid

end

connection

part

F-1300

2,356 14,564

F-1600

lbs

2,374 15,179

431 201 379 704 740 2,724

F-1300

1,069 6,606

F-1600

Kg

1,077 6,885

196 91 172 319 336 1,236

Loading...

Loading...