6

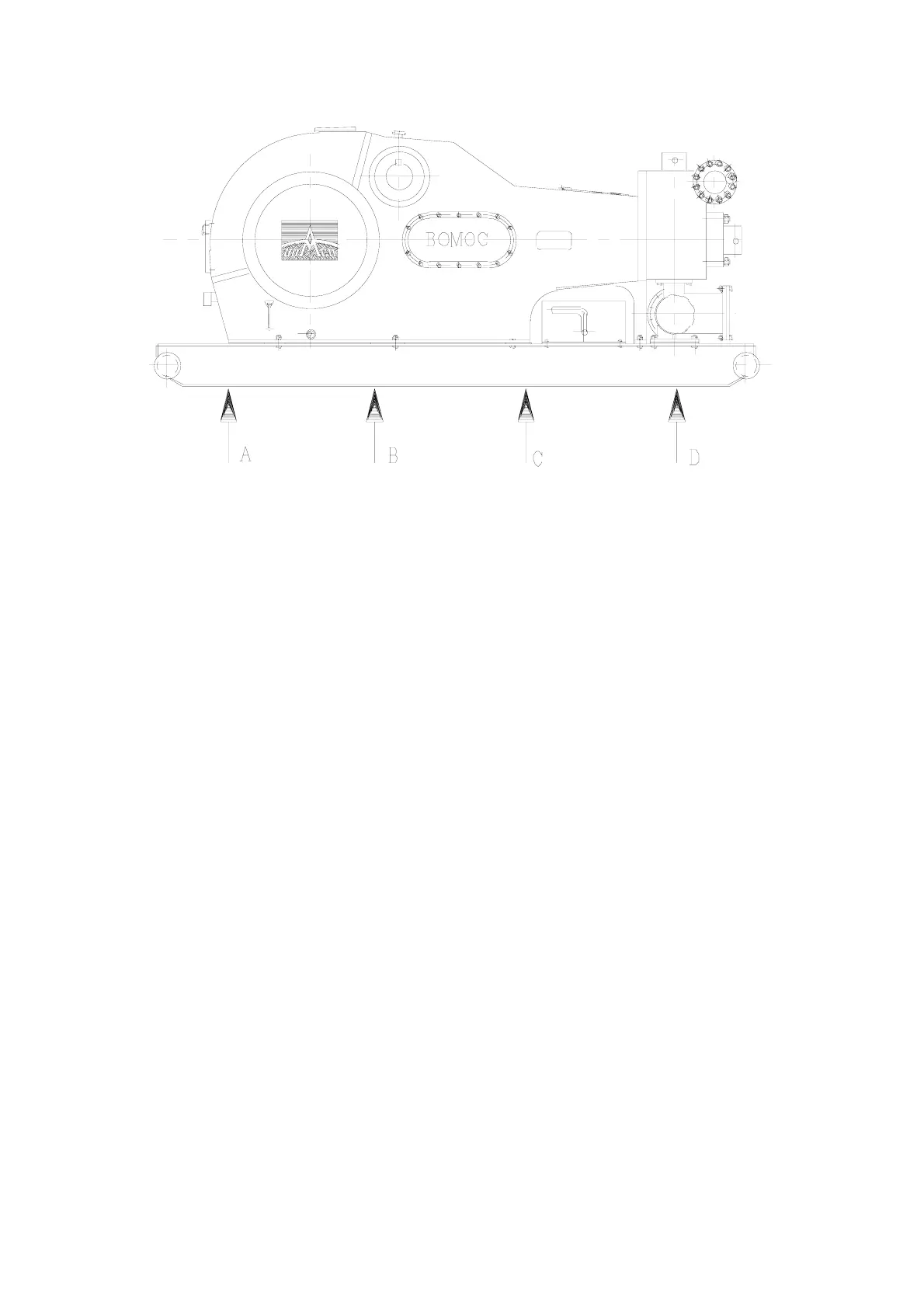

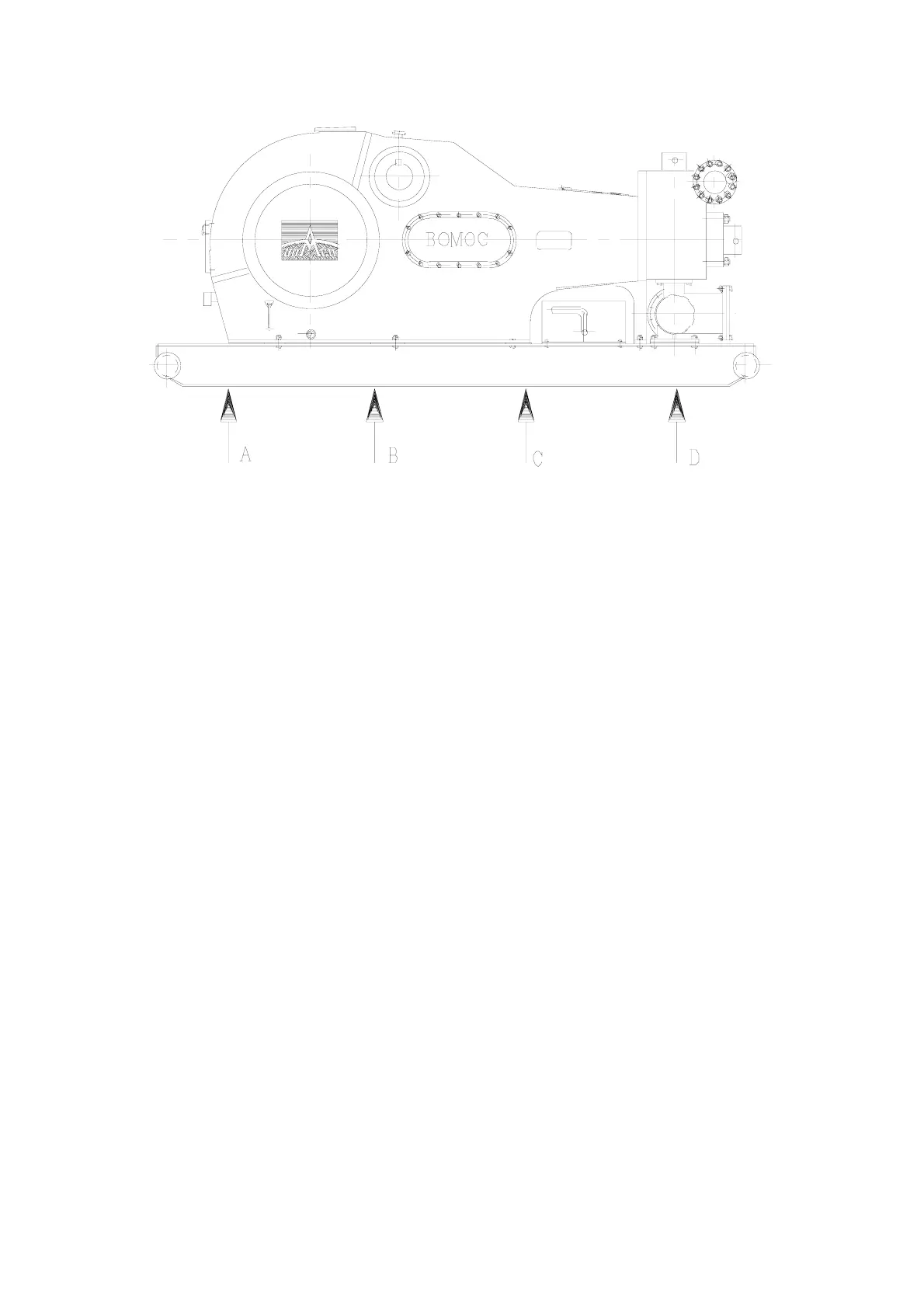

Fig. 2

1.2.1. Ground Installation

When ground installation is going on, 8 pieces of 76mm×305mm boards is cushioned in the direction

of pump skid, as indicated in Fig.2. The base of boards should be 300mm wider than that of pump

skid beam. In the wet or moist circumstance, need solider base.

1.2.2. Permanent Installation

When installing mud pump on the structural base or concrete slab of drilling barge and platform, fix

pump skid with bolts, it is essential that the skid should be properly shimmed to prevent possibility of

twisting or distorting the power frame. The pump skids must sit solid on all shim points with bolts

loose.

On barge installations, the pump skids are generally bolted down to T-beams. Install shims at points

shown in Fig, 2 and 3 and observe caution of proper shimming to prevent twist or distortion. The

shims on all installations should extend the full width of the skid beam flanges and have a minimum

length of 12″ (305mm).

When prime mover, drive device are installed integrally with the pump skids, the preferred installation

would be to set the pump package on the T-beam skids and provide retention blocks rather than bolts

to hold it in place. This will allow the pump to “float” and minimize the transfer of barge deck or

platform distortion into the frame.

Loading...

Loading...