Maintenance and service

C 950/C 1050 (Pro TL 175 C/199 C) – 6 720 805 440 (2019/10)

60

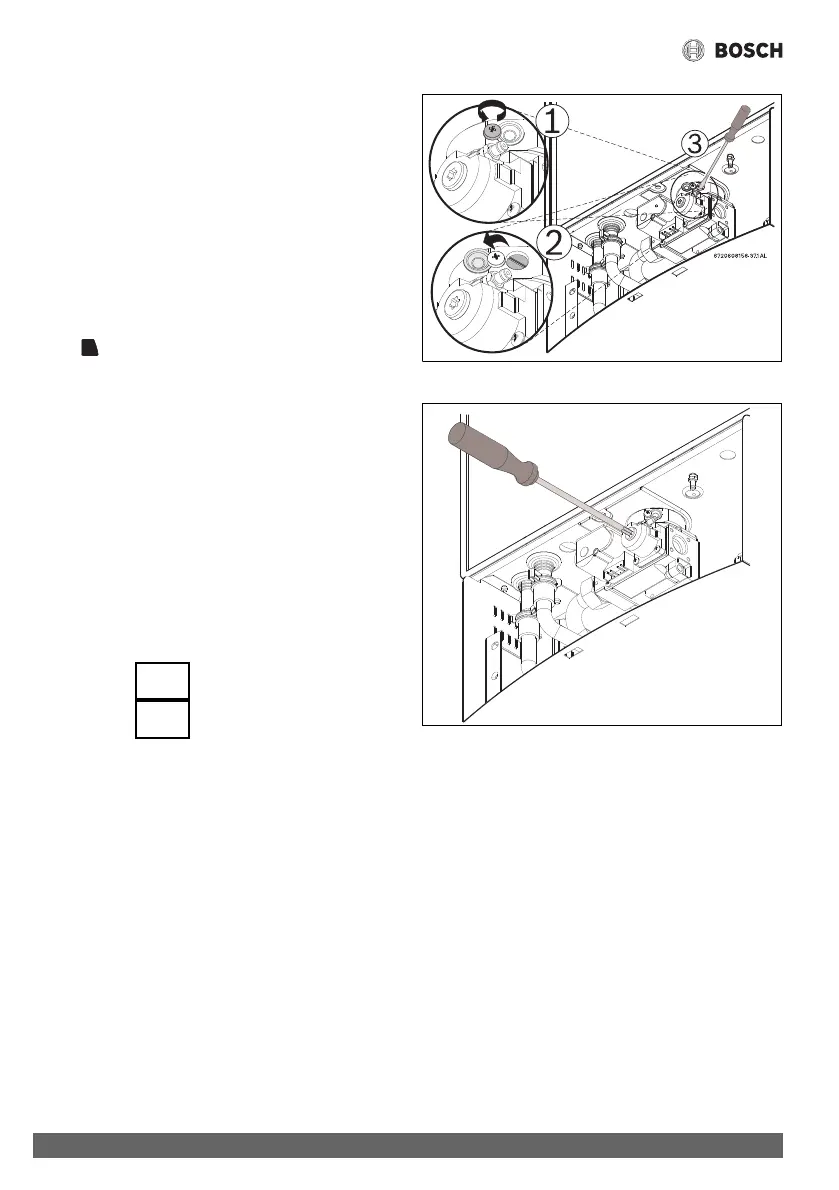

C. Adjusting CO

2

:

Note: P1 adjustment will change the P2 reading. Confirm

the P1 value BEFORE adjusting the P2 level.

1. If P1 CO

2

level is off:

▶ Loosen yellow painted Phillips screw (1) and cover should

rotate down (2) revealing a recessed brass slotted screw.

fig. 74.

▶ Turning the slotted screw counter clockwise will raise P1

CO

2

levels and clockwise will lower P1 CO

2

levels.

Adjustments to the slotted screw will also change P2 CO

2

levels.

▶ After bringing the P1 CO2 readings in proper range, press

the button to enter the P2 mode. Verify CO

2

readings in

P2 mode.

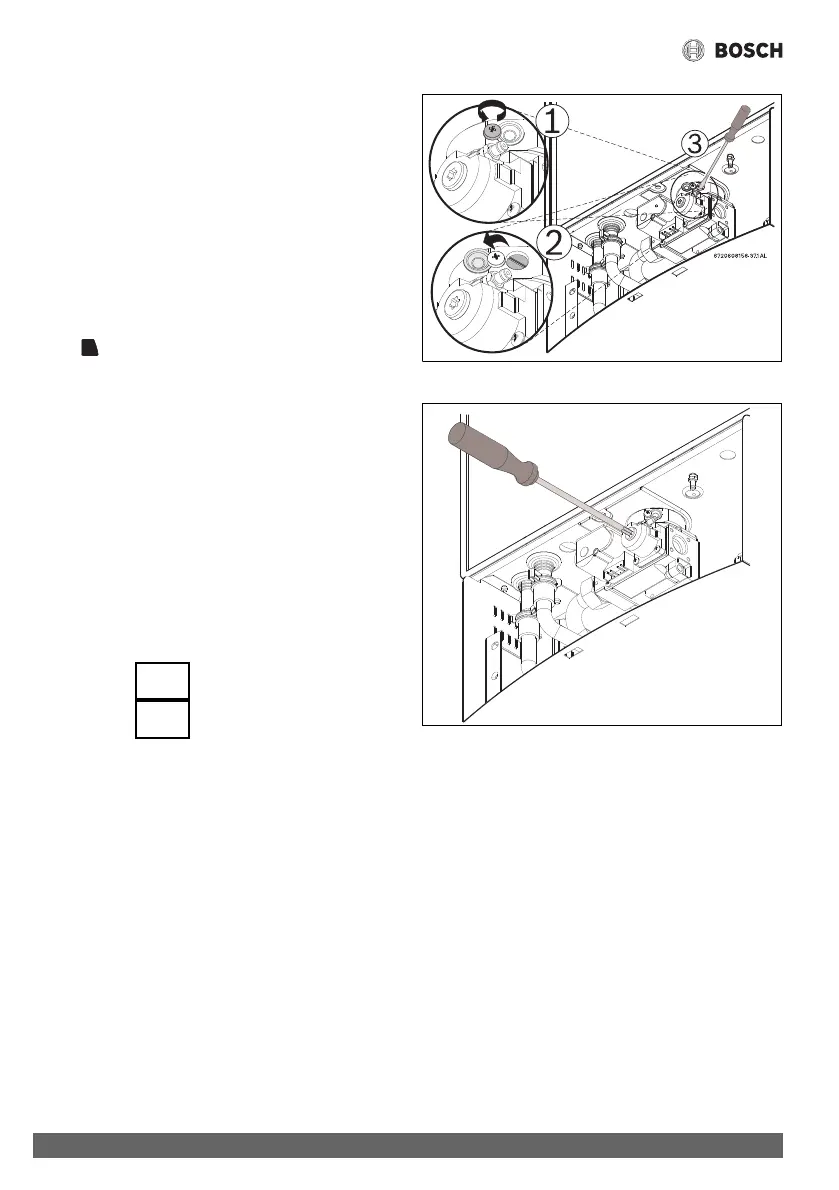

2. If P2 CO

2

level is off:

▶ Remove yellow painted #40 Torx cover from the front of the

gas valve. (fig. 75) A plastic #40 Torx screw will be

revealed.

▶ Turning the plastic #40 Torx screw counter clockwise will

lower P2 CO

2

levels and clockwise will raise P2 CO

2

levels.

Note: This screw adjustment is very sensitive and should be

made in small increments. It may take several minutes for

readings to stabilize.

3. Verify both P1 and P2 CO

2

readings are within the ranges

specified in table 48. Repeat steps 1 and 2 as necessary until

CO

2

values are within the specified ranges.

Final Readings

P1 CO

2

Reading: % CO

2

P2 CO

2

Reading: % CO

2

D. Returning to Service:

1. Return slotted screw cover to original position.

2. Reinstall Torx cover.

3. Remove CO

2

analyzer probe and reinstall flathead screw

with gasket in exhaust collar.

4. Press ON/OFF button to turn OFF the heater and then turn

ON the heater.

5. Heater is ready for normal operation.

Fig. 74 Adjusting P1 CO

2

level

Fig. 75 Adjusting P2 CO

2

level

Loading...

Loading...