English–121 609 929 E91 • (04.10) PS

Checking and Adjusting Basic Adjustment

Before all work on the machine, pull the power

plug.

To ensure precise cuts, the basic adjustment must be

checked and adjusted as necessary after intensive us

age.

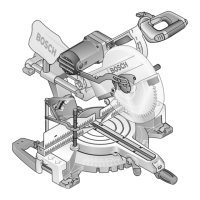

Bevel Angle 33,9° (Vertical)

Place the machine in the working position.

Rotate the saw table 15 to the detent 14 for 0°. Loos

en the clamping lever 30 and pull the fence extension

22 completely out.

Loosen the clamping handle 32 and press the setting

knob 31 completely in. Swing the tool arm with the

handle 1 until the pin 24 rests against the stop bolt 23.

Checking: (see Figure

)

Place a combination square set to 33,9° on the saw

table 15. The leg of the square must be flush with the

saw blade over its entire length.

Adjusting: (see Figure )

Loosen the locking nut of the stop bolt 23 with the

openended wrench 36 (12 mm) provided. Turn the

stop bolt either in or out until the leg of the square is

flush with the saw blade over its entire length.

Retighten the clamping handle 32. Then retighten the

locking nut of the stop screw 23.

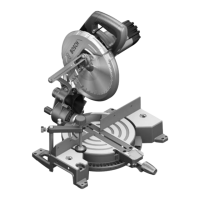

Fence

Place the electrotool in the transport position.

Rotate the saw table 15 to the detent 14 for 0°. Loos

en the clamping lever 30 and pull the fence extension

22 completely out.

Checking: (see Figure

)

Set the combination square to 90° and place it on the

saw table 15. The square must be flush with the fence

6 over its entire length.

Adjusting: (see Figure

)

Loosen all three sockethead screws 35 with the Allen

key 21 (6 mm) provided. Rotate the fence 6 until the

square is flush with the fence over its entire length. Re

tighten the sockethead screws.

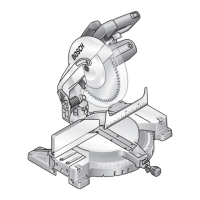

5 MAINTENANCE AND SERVICE

Maintenance

Before all work on the machine, pull the power

plug.

Always keep the machine and the ventilation slits clean

for efficient and safe working.

The swinging guard must always be able to move free

ly and close by itself. Therefore, always keep the area

around the swinging guard clean.

Remove dust and chips by blowing out with com

pressed air or with a brush.

Clean the roller 25 regularly.

Should the tool fail in spite of careful manufacturing

and testing procedures, have the repairs performed by

an authorized customer service location for Bosch

ElectroTools.

For inquiries and spare parts ordering, please include

the 10digit order number on the nameplate of the

tool.

Accessories

Saw blade 254 x 30 mm, 40 teeth. . . 2 608 640 438

Saw blade 254 x 25,4 mm, 40 teeth . 2 608 640 459

Saw blade 254 x 16 mm, 40 teeth. . . 2 608 640 466

Saw blade 254 x 25,4 mm, 120 teeth 2 608 640 465

Quick action clamp . . . . . . . . . . . . . . 2 608 040 205

Table insert . . . . . . . . . . . . . . . . . . . . 2 607 960 014

Dust bag . . . . . . . . . . . . . . . . . . . . . . 2 605 411 187

Extension hoop (356 mm) . . . . . . . . . 2 607 001 911

Angle adapter for dust bag . . . . . . . . 2 608 601 171

Vacuuming adapter for 35 mm hose . 2 605 702 022

Carrying bag . . . . . . . . . . . . . . . . . . . 2 605 435 019

Disposal

Tool, accessories and packaging should be sorted for

environmentfriendly recycling.

The plastic components are labeled for categorized re

cycling.

S1

S2

T1

T2

Loading...

Loading...