English | 17

Bosch Power Tools 1 609 929 W96 | (10/5/10)

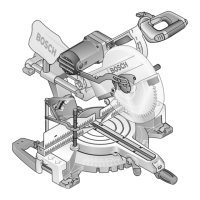

Mounting the Extension Bars

(see figure G)

Long workpieces must be underlaid or support-

ed at their free end.

To extend the saw table additionally, extension

bars can be mounted both to the left or right of

the power tool.

– Insert the extension bars 38 on both sides of

the power tool to the stop in the drill holes

16 intended for this purpose.

– Tighten the screws for securing the exten-

sion bars.

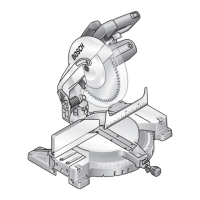

Clamping the Workpiece (see figure H)

To ensure optimum working safety, the work-

piece must always be firmly clamped.

Do not saw workpieces that are too small to

clamp.

– Press the workpiece firmly against the

fence 5.

– Insert the material clamp 17 provided into

one of the holes 14 intended for it.

– Loosen the wing bolt 39 and adapt the mate-

rial clamp to the workpiece. Tighten the wing

bolt again.

– Firmly clamp the workpiece by turning the

threaded rod 40 in clockwise direction.

Loosening the Workpiece

– To release the material clamp, turn the

threaded rod 40 in anticlockwise direction.

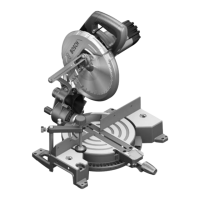

Adjusting the Cutting Angle

f Before any work on the machine itself, pull

the mains plug.

To ensure precise cuts, the basic adjustment of

the machine must be checked and adjusted as

necessary after intensive use (see “Checking

and Adjusting the Basic Adjustment”, page 20).

f Always tighten the locking knob 8 firmly be-

fore sawing. Otherwise the saw blade can

become wedged in the workpiece.

Adjusting Horizontal Mitre Angles

(see figure I)

The horizontal mitre angle can be set in the

range from 47° (left side) to 47° (right side).

– Loosen the locking knob 8 in case it is tight-

ened.

– Pull the lever 9 and turn the saw table 6 until

the desired mitre angle is indicated on the

angle indicator 10.

– Tighten the locking knob 8 again.

For quick and precise setting of often used mi-

tre angles, detents 11 are provided on the saw

table:

– Loosen the locking knob 8 in case it is tight-

ened.

– Pull lever 9 and rotate the saw table 6 left or

right to the requested detent.

– Release the lever again. The lever must be

felt to engage in the detent.

– Tighten the locking knob 8 again.

Adjusting Vertical Bevel Angles (see figure J)

The vertical bevel angle can be set in the range

from –2° to 47°.

– Loosen the clamping lever 19.

– Tilt the tool arm by the handle 2 until the an-

gle indicator 41 indicates the desired bevel

angle.

– Hold the tool arm in this position and retight-

en the clamping lever 19.

For quick and precise setting of the standard

angles 0° and 45°, factory-set stop screws (27

and 18) have been provided for.

– Loosen the clamping lever 19.

– For this, tilt the tool arm by the handle 2 to

the stop toward the right (0°) or to the stop

toward the left (45°).

– Retighten the clamping lever 19 again.

Left Right

0°

15°; 22.5°;

30°; 45°

15°; 22.5°;

30°; 45°

OBJ_BUCH-1247-001.book Page 17 Monday, May 10, 2010 10:21 AM

Loading...

Loading...