English | 35

Bosch Power Tools 1 609 929 T11 | (18.1.10)

The vibration emission level given in this infor-

mation sheet has been measured in accordance

with a standardised test given in EN 61029 and

may be used to compare one tool with another.

It may be used for a preliminary assessment of

exposure.

The declared vibration emission level repre-

sents the main applications of the tool. However

if the tool is used for different applications, with

different accessories or poorly maintained, the

vibration emission may differ. This may signifi-

cantly increase the exposure level over the total

working period.

An estimation of the level of exposure to vibra-

tion should also take into account the times

when the tool is switched off or when it is run-

ning but not actually doing the job. This may sig-

nificantly reduce the exposure level over the to-

tal working period.

Identify additional safety measures to protect

the operator from the effects of vibration such

as: maintain the tool and the accessories, keep

the hands warm, organisation of work patterns.

Declaration of Conformity

We declare under our sole responsibility that

the product described under “Technical Data” is

in conformity with the following standards or

standardization documents: EN 61029 accord-

ing to the provisions of the directives

2004/108/EC, 2006/42/EC.

Technical file at:

Robert Bosch GmbH, Dept. PT/ESC,

D-70745 Leinfelden-Echterdingen

Robert Bosch GmbH, Power Tools Division

D-70745 Leinfelden-Echterdingen

Leinfelden, 18.01.2010

Assembly

f Avoid unintentional starting of the ma-

chine. During assembly and for all work on

the machine, the power plug must not be

connected to the mains supply.

Delivery Scope

Carefully remove all parts included in the deliv-

ery from their packaging.

Remove all packaging material from the machine

and the accessories provided.

Before starting the operation of the machine for

the first time, check if all parts listed below have

been supplied:

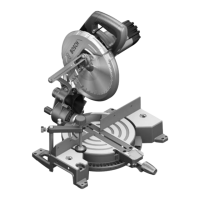

– Chop and mitre saw with mounted saw blade

– Locking knob 12

– Dust bag 27

– Quick-action clamp 7

– Allen key/Phillips screwdriver 21

– Ring spanner 35

Note: Check the power tool for possible dam-

age.

Before further use of the machine, check that all

protective devices are fully functional. Any light-

ly damaged parts must be carefully checked to

ensure flawless operation of the tool. All parts

must be properly mounted and all conditions

fulfilled that ensure faultless operation.

Damaged protective devices and parts must be

immediately replaced by an authorised service

centre.

Mounting the Locking Knob

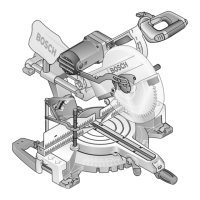

(see figure A)

– Screw the locking knob 12 into the corre-

sponding drill hole above the lever 13.

f Always tighten the locking knob 12 firmly

before sawing. Otherwise the saw blade can

become wedged in the workpiece.

Dr. Egbert Schneider

Senior Vice President

Engineering

Dr. Eckerhard Strötgen

Head of Product

Certification

OBJ_BUCH-1040-001.book Page 35 Monday, January 18, 2010 12:35 PM

Loading...

Loading...